In a significant strategic maneuver aimed at reshaping the manufacturing landscape, the recent appointment of Dave Evans, co-founder of Fictiv, to the presidency of Misumi Americas has set the stage for a monumental integration effort. This leadership transition, coming just nine months after Misumi Group, Inc.’s acquisition of Fictiv in April 2025, is the cornerstone of an ambitious initiative to forge a single, AI-driven digital platform. The mission is to seamlessly merge Misumi’s extensive portfolio of standard and configurable mechanical components with Fictiv’s advanced digital network for custom parts. This fusion represents a direct challenge to the fragmented and often inefficient supply chains that plague modern product development, signaling a deliberate shift toward a deeply integrated, data-centric ecosystem. With Evans continuing to oversee Fictiv while leading Misumi Americas, the plan ensures a cohesive alignment of operations and strategy, heralding a new era of unified manufacturing for customers across the Americas.

A Vision for the Augmented Engineer

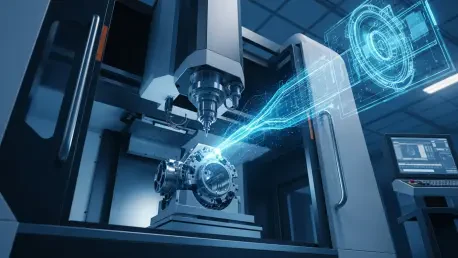

The core philosophy driving this integration is not to replace human ingenuity with artificial intelligence but to augment it, empowering engineers with unprecedented clarity and foresight. This new vision centers on a unified digital platform designed to provide critical, real-time manufacturing context directly within the design phase—a stage where decisions have the most significant impact on cost, quality, and time to market. By embedding sophisticated AI capable of analyzing factors like geometric tolerances, material properties, lead times, and complex supply chain constraints, the platform aims to proactively identify and resolve potential manufacturability issues. This approach allows engineers to make more informed choices earlier in the development cycle, ensuring that innovative designs are also inherently producible, scalable, and resilient. The ultimate objective is a dramatic acceleration of the innovation cycle, enabling companies to transition from an initial concept to full-scale production with remarkable speed and efficiency, fundamentally changing the economics of product development.

This strategic direction moves beyond simple automation to create a symbiotic relationship between the designer and the digital manufacturing ecosystem. The platform will serve as an intelligent co-pilot, leveraging vast datasets to offer predictive insights and design recommendations. For instance, an engineer could receive instant feedback on how a minor design modification might impact production costs or which material offers the best balance of performance and availability for their specific application. This continuous feedback loop, powered by AI, promises to break down the traditional silos that separate design, sourcing, and production. The retirement of Nobuyuki Ashida, who successfully guided Misumi USA through a decade of growth, underscores the significance of this shift. His endorsement of Evans highlights a deliberate pivot toward a leader with a proven track record in digital innovation, signaling that the future of manufacturing lies in the intelligent application of data to overcome long-standing industry challenges.

The Technological and Data-Driven Bedrock

Fueling this ambitious platform is one of the world’s most extensive and rapidly growing manufacturing design datasets, which serves as the technological bedrock for the entire initiative. With Misumi’s digital services currently processing an estimated 10,000 CAD file submissions each day, the company is amassing a rich repository of design and manufacturing information. This immense volume of data is the essential fuel for the platform’s AI engine, enabling it to perform complex functions with remarkable accuracy, from generating automated quotes in seconds to conducting sophisticated Design for Manufacturability (DFM) analyses. Fictiv’s legacy, built by Evans, provides the other critical half of the equation: a pioneering digital marketplace model and a robust, cloud-based infrastructure. This brings invaluable expertise in managing a globally distributed network of vetted manufacturing partners and simplifying the complex logistics of sourcing custom mechanical parts, which will now be integrated into the larger Misumi ecosystem to create a truly end-to-end solution.

The convergence of these two technological powerhouses is designed to accelerate Misumi’s ongoing transformation into a fully digital business. The integration extends the digitization of the entire process—from initial quote to final order placement—across standard, custom, and even mass-production components. By applying machine learning algorithms to the combined dataset, the platform will continuously optimize its processes, improving the accuracy of its manufacturability feedback and refining its supply chain management. This data-driven approach not only enhances efficiency for customers but also builds a more resilient and agile manufacturing network. The system can intelligently route orders to the best-suited manufacturing partner based on capacity, capability, and geographic location, mitigating risks associated with supply chain disruptions. This technological foundation is not merely an upgrade but a complete reimagining of how manufacturing services are delivered, positioning the unified entity to meet the demands of an increasingly fast-paced and technologically advanced market.

A Strategic Focus on Growth and Innovation

The newly consolidated entity has set its sights on a diverse range of high-growth and technologically advanced sectors, strategically positioning itself as an essential partner for innovators at the forefront of modern industry. Key industries targeted for this enhanced service offering include climate tech, robotics, medtech, electric vehicles (EVs), aerospace, and factory automation. This focus reflects a clear understanding that companies in these fields require not only high-precision components but also incredible speed and agility in their development and production cycles. By providing a single, streamlined platform for both standard and custom parts, the unified company aims to become indispensable to engineers and supply chain managers working on next-generation technologies. Geographically, this initiative is anchored in the Americas, a region identified by MISUMI Group Inc.’s President, Ryusei Ono, as one of the company’s most critical growth markets, with an ambitious goal to significantly expand the business by 2030.

This expansion strategy is built on a “fusion” model, combining what the company describes as “Japanese precision and quality with American digital innovation.” To effectively execute this East-West growth plan, Misumi Americas will operate from two distinct but interconnected strategic hubs. The San Francisco Bay Area in California, where Evans will be based, is designated as the center for innovation, AI, and software development, leveraging the region’s rich talent pool in technology. Meanwhile, the Chicago/Schaumburg area in Illinois will serve as the operational core, managing logistics and customer operations and capitalizing on its strategic position as a hub for Midwest manufacturing. This dual-hub approach is designed to connect customers in the United States and Mexico to Misumi’s vast global network, which already serves over 323,000 companies and processes more than 200,000 shipments daily, creating a powerful and responsive supply chain infrastructure to support its growth targets.

The Realized Impact on Product Development

The strategic decisions that led to this integration culminated in a fundamentally redesigned customer experience, transforming how engineers and procurement managers approached product development. The creation of a single-source platform eliminated the friction and delays that previously characterized the process of sourcing both standard and custom components. By providing unified access to millions of Misumi’s configurable parts alongside Fictiv’s rapid manufacturing services, the platform removed the need for juggling multiple vendors and disparate systems. This consolidation delivered a powerful value proposition where development timelines were dramatically accelerated through features like instant digital quoting and AI-powered DFM feedback, which became standard practice. The initiative successfully merged high-precision manufacturing standards with a rigorously vetted and globally distributed supply chain, establishing a new benchmark for quality and resilience that served a wide spectrum of companies, from agile startups to established global original equipment manufacturers (OEMs).