Japan is confronting a profound demographic shift that poses a direct threat to its long-held status as a global manufacturing titan, as a rapidly aging society and a shrinking workforce converge to create critical labor shortages across its industrial landscape. This pressing reality has catalyzed a nationwide pivot toward a technologically advanced future, positioning automation not merely as a tool for enhancing efficiency but as a strategic imperative for economic survival. The nation’s commitment is reflected in the staggering growth trajectory of its industrial automation components market, which was valued at USD 13.70 Billion in 2024 and is forecast to surge to an impressive USD 28.90 Billion by 2033. This monumental investment signals a fundamental re-engineering of Japan’s industrial base, a high-stakes endeavor to build a more resilient, productive, and competitive manufacturing sector capable of thriving in an era of unprecedented demographic change. The core of this transformation is a decisive move away from legacy systems toward sophisticated, interconnected, and intelligent ecosystems designed to compensate for a diminishing human workforce while simultaneously pushing the boundaries of innovation.

The Unavoidable Push Toward Automation

The primary force compelling Japan’s aggressive adoption of automation is a demographic reality that is both stark and irreversible. The nation’s aging population and declining birth rate have resulted in a persistent and intensifying labor shortage, particularly impacting the manufacturing sector that has long been the engine of its economy. This situation has moved automation from the category of operational upgrade to that of an essential utility, necessary for maintaining production levels, fulfilling orders, and ensuring economic stability. Companies are no longer asking if they should automate, but how quickly and comprehensively they can do so to bridge the widening gap left by a retiring generation of skilled workers. This demographic imperative creates a powerful, sustained demand for automated solutions, as manufacturers are compelled to invest in technology to perform tasks that a shrinking human workforce can no longer support, ensuring that factories remain operational and productive. This isn’t just about replacing labor; it’s about preserving the very capacity of the nation’s industrial heartland in the face of an unavoidable demographic winter.

This race to automate is further accelerated by the relentless pressure of global competition and the national imperative to uphold a reputation for unparalleled quality and productivity. In a fierce global marketplace, Japanese manufacturers must continually innovate to stay ahead of rivals, particularly those in regions with lower labor costs. Automation provides the primary pathway to achieving this, enabling a level of precision, speed, and consistency that manual processes cannot match. By minimizing human intervention, automated systems drastically reduce errors, optimize the use of resources, and increase throughput, allowing Japanese companies to compete on value and technological superiority rather than price alone. The Japanese government has recognized the strategic importance of this transition, acting as a powerful catalyst through targeted policy frameworks, substantial financial incentives, and the cultivation of public-private partnerships. This national strategy underscores a unified vision: embracing advanced manufacturing is not just a commercial decision for individual firms but a cornerstone of Japan’s long-term economic health and its continued leadership on the world stage.

The Dawn of the Smart Factory

At the core of Japan’s industrial evolution is the strategic pivot from traditional, isolated manufacturing processes to the integrated, data-driven paradigm of Industry 4.0, often termed the “smart factory.” This represents a fundamental shift in philosophy, envisioning a manufacturing environment where machines, robotics, enterprise systems, and human operators are seamlessly interconnected within a single, cohesive digital ecosystem. The goal is to achieve an unprecedented level of real-time operational visibility, agility, and control. This interconnectedness allows for advanced capabilities such as mass customization, where production lines can rapidly adapt to individual customer orders, and real-time decision-making, where data from the factory floor instantly informs business strategy. The move toward smart manufacturing is not an incremental improvement but a complete reimagining of the production process, designed to create factories that are not only more efficient but also more intelligent, responsive, and resilient to market changes. This transition is creating immense demand for a new generation of automation components capable of supporting these complex, data-rich environments.

This manufacturing revolution is being powered by the synergistic convergence of several transformative technologies, with the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics at the forefront. These technologies are no longer confined to research labs but are being actively deployed on factory floors, creating a virtuous cycle of continuous improvement. IoT sensors act as the nervous system of the smart factory, collecting vast amounts of granular data on everything from machine temperature and vibration to environmental conditions. This data is the fuel for AI and machine learning algorithms, which serve as the factory’s brain. AI-powered computer vision systems can perform quality inspections with superhuman speed and accuracy, identifying microscopic defects that would escape the human eye. Machine learning models analyze historical data to enable predictive maintenance, anticipating equipment failures before they occur. This shifts the maintenance paradigm from reactive to proactive, drastically reducing unplanned downtime and extending the lifespan of critical assets. This data-driven intelligence is then physically manifested through the deployment of advanced robotics, creating a powerful feedback loop where data informs intelligent action, and that action generates new data for further optimization.

Technology Transforming Key Industries

The widespread adoption of these advanced automation components is not a monolithic trend but is being strategically deployed to address the unique challenges and opportunities within Japan’s diverse and powerful industrial sectors. The automotive industry, a traditional cornerstone of the Japanese economy, stands as one of the largest consumers of automation. The escalating complexity of modern vehicles—from the intricate assembly of electric vehicle powertrains and batteries to the integration of sophisticated advanced driver-assistance systems (ADAS) and in-car electronics—demands a level of precision and flexibility that can only be achieved through highly automated production lines. Robotics and AI-driven quality control are essential for ensuring the safety and reliability of these complex systems, allowing manufacturers to innovate at a rapid pace while maintaining the highest standards of quality that consumers expect from Japanese brands. This sector’s heavy investment in automation is a clear indicator of the technology’s critical role in shaping the future of mobility.

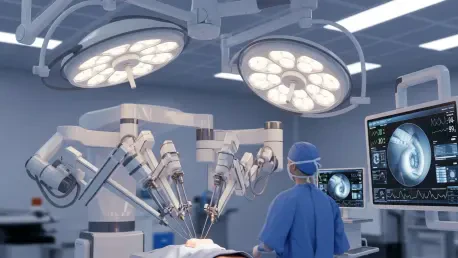

This transformative impact extends far beyond the automotive sector, permeating other critical industries. In the electronics and semiconductor sectors, manufacturing processes operate at the cutting edge of precision, often involving nanometer-level tolerances and the absolute necessity of pristine cleanroom environments. Here, extensive automation and robotics are not just beneficial but are an absolute requirement for production. Similarly, the pharmaceutical and healthcare sectors are rapidly embracing automation to navigate stringent regulatory compliance, guarantee product safety, and meet the demands of a growing and aging population. High-profile examples, such as AI-assisted surgical robots and fully automated pharmacy systems that manage everything from prescription scanning to medicine dispensing, showcase the high level of sophistication being implemented. Even traditionally labor-intensive sectors like food and beverage are turning to automation to overcome labor shortages while meeting consumer demands for greater product variety, stringent quality assurance, and enhanced traceability for food safety. Meanwhile, the logistics and warehousing sector has been completely reshaped by the e-commerce boom, where automated storage and retrieval systems (AS/RS) and autonomous mobile robots (AMRs) have become standard equipment in modern distribution centers, enabling them to handle immense order volumes at the relentless speed the digital marketplace demands.

Forging a Resilient Future

Looking ahead, the trajectory of Japan’s industrial automation market is set for sustained and robust expansion through 2033 and beyond. The primary forces propelling this growth are not temporary trends but deep structural shifts that will only intensify over time. The demographic pressures stemming from an aging and shrinking workforce are irreversible, ensuring a permanent, baseline demand for automation solutions as companies seek to maintain and expand their operational capacity. This guarantees that automation will remain a central pillar of the nation’s long-term industrial strategy. Concurrently, the core technologies driving this transformation, such as artificial intelligence and the Internet of Things, will continue to mature. As they become more powerful, accessible, and cost-effective, their adoption is expected to accelerate dramatically, particularly among the small and medium-sized enterprises (SMEs) that form the backbone of Japan’s economy but have historically been more cautious about large-scale technology investments. This democratization of advanced technology will broaden and deepen the impact of automation across the entire industrial landscape.

Ultimately, the projected growth of Japan’s industrial automation components market was the outcome of a powerful, multi-faceted national strategy. It stood as a decisive and necessary response to profound demographic shifts, a critical tactic for maintaining global manufacturing leadership, and a forward-looking embrace of the transformative potential of digital technology. This evolution successfully positioned Japan’s manufacturing sector to be more productive, sustainable, and competitive for the decades that followed. The journey from reacting to a crisis to proactively re-engineering the nation’s industrial foundation was a lesson learned from past economic challenges and global supply chain disruptions. This experience solidified a national commitment to technological self-reliance, ensuring that Japan not only navigated its demographic challenges but also emerged with a more resilient and innovative economic engine prepared for the future.