The construction industry is undergoing a significant transformation, driven by technological advancements and an increasing need for efficiency. Central to this evolution is the groundbreaking work of Bedrock Robotics, a company that has emerged as a leader in autonomous systems specifically designed for construction. With the infusion of $80 million in funding and a focus on upgrading existing machinery to incorporate autonomous technology, Bedrock Robotics addresses many of the challenges the industry faces today. As the global construction market continues to expand, reaching a valuation of $13 trillion, the need for innovative solutions to combat labor shortages and meet rising demand becomes more urgent. This article explores how Bedrock Robotics is positioned to revolutionize construction through automation, partnerships, and strategic initiatives, painting a vivid picture of the industry’s future.

Bedrock Robotics’ Revolutionary Approach

Redefining Automation in Construction

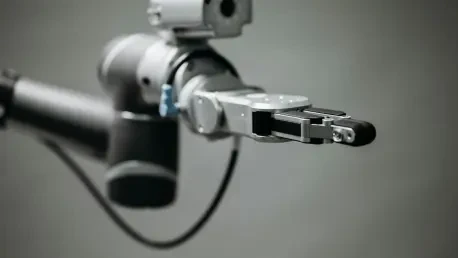

Bedrock Robotics stands at the forefront of a technological revolution within the construction sector, leveraging artificial intelligence to transform traditional building methods. The company’s groundbreaking approach centers on the automation of heavy equipment, which is designed to alleviate the challenges posed by labor shortages and the relentless demand for new infrastructure. The ability of Bedrock Robotics to merge cutting-edge autonomous technology with existing machinery marks a significant departure from conventional business models that often necessitate the design and sale of brand-new equipment at substantial costs. The core innovation lies in Bedrock’s ability to retrofit heavy machinery with reversible hardware and software systems, enabling swift deployment and operational autonomy within just one day.

In an industry experiencing a decrease of 500,000 workers, coupled with an expectation of further shrinkage as a significant portion of the workforce nears retirement, automation offers a lifeline. By upgrading existing equipment rather than replacing it, Bedrock efficiently extends the working life of machinery, which is crucial for meeting the growing demand for construction projects. This approach not only optimizes resources but also cuts down on initial expenditures, making it a more accessible solution for construction firms of all sizes. The adoption of autonomous systems is not merely a reaction to labor shortages but a proactive strategy to enhance productivity, safety, and efficiency across building sites globally.

Enhancing Efficiency through Strategic Collaborations

Strategic collaborations play a crucial role in the successful deployment and continued improvement of Bedrock Robotics’ autonomous systems. Through partnerships with influential industry players such as Sundt Construction and various Texas-based firms, Bedrock ensures its technology undergoes rigorous field testing, which is essential for refinement and adaptation to different construction environments. These alliances foster a collaborative approach to innovation, leveraging expertise from both the construction and technology sectors to address common industry challenges effectively.

The participation of established construction firms in the development and testing of Bedrock’s technology adds a level of credibility and reassurance for potential adopters. It demonstrates that these autonomous systems can be seamlessly integrated into existing workflows, complementing traditional construction processes rather than disrupting them. By aligning with partners who are industry veterans, Bedrock can fine-tune its offerings to meet real-world demands, thereby accelerating the pace of adoption across the industry. As these collaborations expand, they set a benchmark for future technological innovations, indicating that partnerships are vital for achieving scalable solutions in construction automation.

The Growing Impact of Automation

Shaping the Future of Construction

The integration of automation into the construction industry is a significant aspect of broader economic and industrial trends. In recent years, the movement towards reindustrialization has gained momentum, with the U.S. witnessing a record $238 billion investment in manufacturing facilities. Automation in construction is not merely an isolated trend but a critical component in aligning infrastructure development with economic growth and market demands. As the industry progresses, the integration of sophisticated automation tools becomes increasingly indispensable, enabling construction firms to execute projects more efficiently and safely.

Stakeholders in the construction sector widely recognize the transformative potential of automation. By automating labor-intensive tasks, these technologies are pivotal in reducing project costs, optimizing schedules, and achieving higher safety standards on construction sites. Furthermore, the deployment of automation systems enhances predictive capabilities, allowing companies to better forecast project outcomes and risks, thus improving overall decision-making processes. This comprehensive approach ensures that automation technologies are viewed not just as a temporary solution to labor shortages but as a permanent fixture in future-proofing the industry.

Benefits and Challenges of Industry Integration

While the advantages of automation in construction are numerous, the integration of such technology is not without its challenges. One of the significant benefits lies in the cost-effectiveness and scalability of upgrading existing equipment through companies like Bedrock Robotics. This approach offers a smooth integration path, reducing the need for companies to engage in costly and lengthy acquisition processes for new machinery. By building upon the existing infrastructure, automation can be seamlessly incorporated into current practices, driving incremental value without significant disruption.

However, the success of automation in construction hinges heavily on overcoming obstacles related to technology adaptation and workforce transition. Ensuring that current employees are effectively trained and reskilled for working alongside autonomous systems is vital for the harmonious coexistence of human and robotic operations. In addition, addressing cybersecurity concerns related to the deployment of AI-driven systems on job sites is paramount to preserving operational integrity and data security. Despite these challenges, the industry consensus is clear: the benefits of automation far outweigh the potential drawbacks, positioning it as a linchpin in the construction industry’s evolution.

Conclusion: Pioneering a New Construction Era

Bedrock Robotics is leading a significant technological shift in the construction industry by harnessing artificial intelligence to innovate building methods. Their pioneering strategy involves automating heavy equipment to counter labor shortages and meet the growing demand for infrastructure. Unlike traditional models that require purchasing new, costly machinery, Bedrock Robotics focuses on integrating advanced autonomous technologies with existing equipment. This novel approach allows for the retrofitting of heavy machinery with reversible hardware and software, enabling rapid deployment and achieving operational autonomy within a day.

In the face of a workforce reduction by 500,000 and an impending decline as many workers approach retirement, automation emerges as a critical solution. Bedrock Robotics promotes the longevity of current machinery by upgrading instead of replacing it, a strategy vital for fulfilling the increasing need for construction projects. This method not only maximizes available resources but also reduces upfront costs, providing a viable option for construction companies of any size. Implementing autonomous systems transcends a mere response to labor shortages; it is an insightful approach to boost productivity, safety, and operational efficiency on construction sites worldwide. Bedrock’s vision marks a potential turning point in how construction adapts to pressing global challenges.