The proliferation of desktop 3D printing has brought incredible creative power to hobbyists and professionals alike, but it has also generated a growing mountain of plastic waste from failed prints, support structures, and discarded prototypes. For years, the community has dreamed of a “closed-loop” system, an accessible way to transform this plastic scrap back into usable material, and now, a major industry player is testing the waters with a potential solution. Creality is currently gauging public interest in a new, two-part desktop system designed to shred, dry, and extrude waste plastic into a fresh spool of filament. Showcased as a functional prototype on a company-branded crowdfunding site, this project represents a significant step toward making home-based filament recycling a practical option. The company is actively soliciting feedback through surveys to understand user needs and price expectations, indicating that the future of this ambitious device hinges directly on the community’s response to its promise of a more sustainable printing workflow.

A Glimpse into the Mechanics

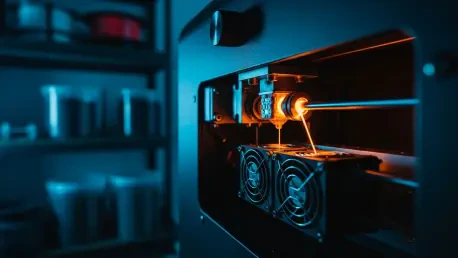

The proposed system is composed of two distinct but complementary machines, the Shredder R1 and the Filament Maker M1, which together occupy a footprint just under a meter long and stand at a height comparable to that of a large Core XY 3D printer. The process begins with the user feeding plastic waste into the Shredder R1, which grinds the material into uniform particles of 4mm or less while also incorporating a drying function to remove moisture—a critical step for ensuring print quality. Once processed, these particles must be manually transferred from the shredder’s collection bin to the hopper of the Filament Maker M1. From there, the machine takes over, melting the plastic and extruding it into a continuous strand. A carriage moving along a set of rails gently pulls this newly formed filament across cooling points to help it solidify and stabilize before it is wound onto a spool. The initial setup appears to require some manual intervention, as the user must thread the filament onto the spool to begin the winding process, a hands-on approach for a semi-automated system.

Beyond its primary function of recycling, the system is engineered to be a versatile tool for material experimentation, empowering users to become small-scale filament manufacturers in their own right. The design allows for the combination of recycled plastic with virgin pellets, providing a way to extend material life and maintain a higher level of consistency. More excitingly, it opens the door to creating custom filaments by introducing additives. Users could potentially mix in natural fillers like coffee grounds or wood dust for unique textures, add scented materials for aromatic prints, or blend different colored plastics to produce custom shades and even unique rainbow-gradient filaments. The system is reported to be compatible with a wide array of eight common 3D printing materials, including PLA, PETG, ABS, ASA, PA, PC, TPU, and PET. This broad compatibility underscores the machine’s potential to move beyond simple waste reduction and become a platform for innovation and personalization, giving creators unprecedented control over the very medium they print with.

Performance and Practical Hurdles

Creality has put forward some ambitious performance claims for its prototype, stating that the Filament Maker M1 can produce a full one-kilogram spool of filament in just one hour. While this production speed is impressive for a desktop unit, the ultimate success of any filament rests on its dimensional accuracy. For filament made from 100% virgin pellets, the system reportedly achieves a tolerance of ±0.05mm, which is in line with the standards of many professional filament brands and should ensure reliable, high-quality prints. However, the tolerance widens to ±0.1mm when using recycled material. This level of variation, while potentially workable on a well-calibrated and robust 3D printer, introduces a significant risk of printing artifacts, inconsistent extrusion, and even nozzle clogs. For context, premium filament manufacturers like Prusa Research pride themselves on a much tighter tolerance of ±0.02mm. The discrepancy highlights a fundamental challenge: maintaining precision while working with the inherent inconsistencies of recycled plastics.

The most significant obstacle standing between the dream of home recycling and its practical implementation has always been material contamination. The chemistry of 3D printing plastics is precise, and even a minuscule amount of a foreign polymer can compromise an entire batch of filament. For instance, a single stray piece of ABS mixed into a batch of PLA can fail to melt correctly, leading to a clogged print head and a ruined project. This sensitivity is why industrial recycling facilities often refuse to process consumer-sourced 3D printing scrap, as the risk of cross-contamination is too high without rigorous, large-scale sorting and purification processes. A desktop system, by its very nature, shifts the burden of ensuring material purity entirely onto the user. To be successful, operators of this machine would need to maintain strict discipline in sorting their plastic waste by type, a challenge that could prove to be a significant barrier to widespread adoption and a critical factor in the quality of the final recycled filament.

The Path to Market

The development of this recycling system was clearly positioned in an exploratory engineering phase, with Creality utilizing its crowdfunding platform not for funding, but as a barometer for market demand. By presenting a functional prototype without a firm price point or release schedule, the company effectively initiated a conversation with its user base. This strategy allowed for the collection of invaluable feedback through a linked survey, probing potential customers on their pain points with 3D printing waste and, crucially, their price expectations for a viable solution. This cautious approach suggested an acknowledgment of the inherent risks and challenges in bringing such a novel product to the consumer market. The project’s ultimate fate—whether it would proceed to mass production or be relegated to the annals of interesting experiments—depended heavily on the community’s demonstrated willingness to embrace the responsibilities and costs associated with at-home filament production, a decision that would shape the future of sustainable desktop manufacturing.