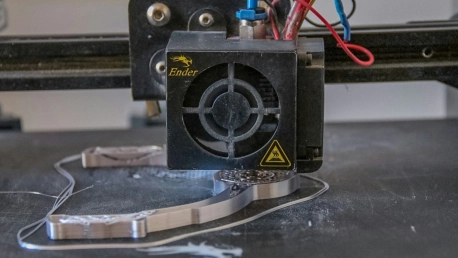

In recent years, the manufacturing sector has witnessed transformative innovations, particularly in the realm of 3D printing. Mantle, a leader in metal 3D printing technology for precision tooling, has made headlines by raising $20 million in a Series C funding round. This development signals a promising shift for American manufacturing, highlighting the potential of 3D printing to overcome longstanding challenges. From addressing labor shortages to reshoring manufacturing processes, Mantle’s cutting-edge technology is poised to make a significant impact. The influx of funds positions Mantle to expand its market reach, boost manufacturing capacity, and push the boundaries of what is possible in precision tooling. The company’s groundbreaking work reflects broader trends in technology and manufacturing, offering solutions that could redefine industry standards.

Financial Milestone and Strategic Vision

Mantle’s recent accomplishment in raising $20 million has undeniably bolstered its position within the industry. This influx of capital elevates its total funding to over $61.5 million, confirming investor confidence in the company’s vision. The investment was led by Schooner Capital and strongly supported by existing investors like Fine Structure Ventures, Foundation Capital, Corazon Capital, 11.2 Capital, and Build Collective. Such robust financial backing underscores the significant trust that stakeholders place in Mantle’s groundbreaking technology and its potential to reshape the manufacturing landscape.The financial backing will facilitate Mantle’s efforts to enhance its market presence and manufacturing capabilities. It also promises the development of innovative capabilities and new materials, further solidifying Mantle’s technological edge. This strategic vision will enable the company to meet the growing demand for precision tooling, particularly within the United States. The funds will not only accelerate the adoption of their TrueShape platform but also ensure the continuous development of advanced materials and capabilities that align with market needs. Mantle’s strategic focus on enhancing its technological prowess indicates a clear pathway toward setting new standards in the metal 3D printing space, making American manufacturing more competitive on a global scale.

The Impact of 3D Printing on Tooling Industry

Metal 3D printing, especially Mantle’s advanced TrueShape platform, is set to revolutionize the tooling industry. The TrueShape technology stands out for its unparalleled speed and cost savings, addressing vital needs in the sector. As traditional methods struggle to keep pace with modern demands, 3D printing offers an efficient alternative to outdated practices. TrueShape’s precision and efficiency translate into significant cost reductions and faster production cycles, setting a new benchmark in the production of tools. This innovation is not just about making production more cost-effective; it also enhances the quality and durability of tools. For manufacturers grappling with high production costs and limited tool life, Mantle’s technology provides a viable solution that delivers superior outcomes.The company’s technology significantly reduces the time required to produce high-quality molds and dies, offering a level of precision and finish that traditional methods cannot match. This translates to substantial savings, both in terms of cost and time, enabling companies to get their products to market more quickly. The efficiency and precision of Mantle’s 3D printing technology also mean that tools last longer, offering a better return on investment. These benefits make Mantle’s technology not just a cost-saving measure but also a strategic asset that can enhance a company’s competitive edge in the market. The TrueShape platform is thus a game-changer, providing a seamless and efficient alternative to labor-intensive and time-consuming traditional methods.

Reshoring Manufacturing to the United States

The global supply chain has shown vulnerabilities, prompting a surge in reshoring manufacturing to the U.S. Mantle’s 3D printing technology emerges as a critical enabler in this transition. By bringing production back home, companies can mitigate risks associated with overseas dependencies and lengthy supply chains. Reshoring provides an opportunity for the U.S. manufacturing sector to leverage advanced technologies, thereby boosting domestic capabilities and enhancing responsiveness to market demands. Mantle’s 3D printing solutions play a pivotal role in this context, offering the means to produce high-quality tools efficiently and cost-effectively on American soil.Reshoring also aligns with the strategic interest of boosting domestic manufacturing capabilities. With advanced technologies like Mantle’s, the U.S. manufacturing sector can gain a competitive edge, ensuring quicker response times to market needs and enhancing overall industry resilience. This movement not only reinvigorates local industries but also promises to create new jobs and foster economic growth. By reducing dependence on international suppliers, U.S. manufacturers can better control quality and production timelines, leading to higher standards and greater reliability in final products. Mantle’s role in this reshoring trend is crucial, as its technology ensures that domestic production remains both feasible and competitive, setting the stage for sustained industrial growth.

Addressing Labor Shortages with Automation

One of the most pressing issues in American manufacturing is the shortage of skilled toolmakers. The aging workforce exacerbates this problem, leaving a gap that traditional training programs struggle to fill. Mantle’s 3D printing solution offers a compelling answer by automating significant aspects of the tooling production process. Automation through advanced manufacturing technologies like those developed by Mantle enhances labor productivity and reduces reliance on a limited skilled labor pool, making it a crucial tool for modern manufacturing.Automation in manufacturing through 3D printing enhances labor productivity, reducing reliance on a limited skilled labor pool. This technology democratizes the production process, enabling even smaller players to compete effectively. By automating tool production, Mantle helps manufacturers maintain high productivity levels despite workforce challenges. The ease of use and efficiency of Mantle’s TrueShape platform mean that less experienced workers can produce high-quality tools, bridging the skill gap and ensuring a steady flow of production. This level of automation enables companies to scale operations without being hampered by labor shortages, making it a pivotal factor in the future of manufacturing.

Success Stories and Industry Adoption

The practical benefits of Mantle’s technology are already evident through its adoption by industry players like Heyco Products. These companies have reported dramatic improvements in operational efficiency and time-to-market. By leveraging Mantle’s 3D printing capabilities, they can develop products more swiftly and at reduced costs. The success stories of Heyco and other early adopters serve as powerful testimonials to the transformative potential of Mantle’s technology. They highlight not only the cost savings but also the enhanced quality and performance of the tools produced using this innovative platform.Success stories serve as powerful testimonials for the transformative potential of Mantle’s technology. Companies using this advanced tooling method are not just witnessing cost savings but also achieving superior quality and performance in their products. These achievements reinforce the technology’s value proposition, making a strong case for wider industry adoption. The positive experiences of these firms underscore the tangible benefits of Mantle’s technology, paving the way for broader acceptance across the manufacturing sector. Mantle’s innovative solutions have proven their worth in real-world applications, demonstrating that 3D printing can deliver on its promises of efficiency and quality.

Enhancing Production and Cost Efficiency

Mantle’s technology is particularly adept at producing high-quality molds and dies. Traditional methods are time-consuming and expensive, but Mantle’s approach significantly cuts down both variables. The resulting precision, superior surface finishes, and reliable metal properties set a new standard for the industry. One of the key advantages is the substantial cost savings—up to 65 percent—coupled with development times reduced by 90 percent. This shift from producing parts to crafting specialized tools highlights Mantle’s focus on resolving core issues in mass production, making their technology indispensable for modern manufacturing needs.The efficiency gained from 3D printing translates to quicker development cycles and enhanced productivity across the board. Mantle’s technology enables manufacturers to bring products to market faster and with fewer resources, providing a competitive edge in a fast-paced industry. The precision and quality of the tools also mean that products are of higher quality, reducing the need for frequent replacements and maintenance. Mantle’s approach not only makes production more sustainable but also more profitable, as companies can get more from their investments. The emphasis on improving production efficiency and reducing costs underscores the transformative potential of Mantle’s 3D printing technology.

Real-World Impacts and Future Prospects

Metal 3D printing, particularly Mantle’s cutting-edge TrueShape platform, is poised to transform the tooling industry. TrueShape technology distinguishes itself with unmatched speed and cost-efficiency, addressing critical industry needs. As conventional methods lag behind modern demands, 3D printing offers a streamlined alternative to outdated techniques. TrueShape’s precision and efficiency lead to notable cost reductions and quicker production cycles, establishing a new standard for tool manufacturing. This innovation goes beyond cost-effectiveness; it also improves the quality and durability of tools. For manufacturers facing high production costs and short tool lifespans, Mantle’s technology is a viable solution that delivers superior results.The company’s technology dramatically cuts the time needed to create high-quality molds and dies, achieving a precision and finish that traditional methods can’t rival. This results in significant savings in both cost and time, helping companies bring products to market faster. The efficiency and precision of Mantle’s 3D printing also mean that tools have a longer lifespan, offering a better return on investment. These advantages make Mantle’s technology not just a cost-saving measure, but also a strategic asset that can enhance a company’s competitive position. The TrueShape platform is thus a game-changer, presenting a seamless and efficient alternative to labor-intensive, time-consuming traditional methods.