In a world where manufacturing faces mounting pressures to become more efficient and cost-effective, a groundbreaking startup has emerged with a bold vision to transform the industry through automation. MicroFactory, a robotics innovator, has recently captured attention by securing $1.5 million in pre-seed funding from notable investors, achieving a post-money valuation of $30 million. This capital injection is set to accelerate the development of a compact, AI-powered robotic system that promises to redefine how small and mid-sized businesses approach production. With affordability and versatility at its core, this technology could potentially bridge the gap between high-cost industrial automation and the needs of smaller enterprises, sparking curiosity about whether such a solution could indeed reshape the manufacturing landscape.

Breaking New Ground in Robotics

Unveiling a Compact Automation Solution

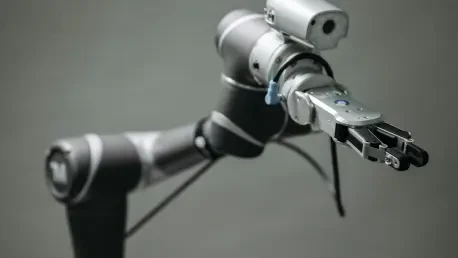

MicroFactory’s flagship offering is a desktop-sized, box-shaped robotic system that stands out for its simplicity and efficiency, priced at an accessible $5,000. Unlike more complex humanoid robots, this design forgoes unnecessary features like legs or intricate hand structures, focusing instead on dual robotic arms with interchangeable tools. The enclosed setup ensures consistent lighting and camera positioning, which not only enhances safety in both home and professional settings but also streamlines training and data handling. Capable of performing tasks such as precision soldering, pick-and-place operations, and even light food processing, the robot has already garnered over 100 paid reservations from industries ranging from electronics to textiles. With commercial units expected to ship by early 2026, this system is poised to offer a practical alternative to traditional automation, particularly for businesses seeking scalable solutions without breaking the bank.

Targeting Diverse Industrial Needs

The versatility of MicroFactory’s robotic system is a key factor in its early success, as it addresses a wide array of industrial applications with ease. From cable routing to peeling adhesive films, the robot’s capabilities extend across sectors like laboratory automation and food packaging, making it a valuable asset for varied production environments. This adaptability is especially significant for small and mid-sized enterprises that often lack the resources to invest in specialized machinery. By providing a single, multi-functional device, MicroFactory enables these businesses to automate repetitive tasks, thereby improving efficiency and reducing labor costs. The strategic focus on electronics assembly as an initial application further demonstrates the potential for self-sustaining production, where robots could eventually assemble more robots, hinting at a future of fully automated manufacturing lines within reach of smaller players in the market.

Shaping the Future of Manufacturing Automation

Simplifying Adoption Through Intuitive Design

One of the most compelling aspects of MicroFactory’s technology is its user-friendly approach to training and operation, which eliminates the need for complex programming skills. Instead, the system learns through human demonstration, significantly lowering the barrier to entry for businesses without dedicated technical staff. This design choice is particularly impactful for small and mid-sized companies, which form the primary target market for this innovation. A notable demonstration showcased the robot assembling a product previously manufactured overseas, proving its ability to support onshore production while maintaining affordability. CEO Igor Kulakov has emphasized that such tabletop automation does not require humanoid features, prioritizing practicality over flashy design. This focus on simplicity and safety could encourage wider adoption, potentially transforming how smaller manufacturers integrate automation into their workflows over the coming years.

Envisioning a Global Automation Network

Looking beyond immediate applications, MicroFactory harbors ambitious plans to deploy 100 million robots worldwide, aiming to automate a substantial portion of manual labor across industries. The long-term vision includes driving hardware costs below $1,000 per unit, making automation accessible to an even broader audience. By targeting smaller businesses initially, the company anticipates generating a diverse dataset from varied use cases, which will enhance the AI capabilities of its robots over time. This cycle of deployment, data collection, and improvement could accelerate innovation, positioning the technology as a cornerstone of future manufacturing. The emphasis on scalability aligns with a growing industry trend toward accessible automation solutions, suggesting that such advancements might not only disrupt traditional production models but also democratize access to cutting-edge tools, reshaping economic dynamics on a global scale.

Reflecting on a Transformative Journey

Reflecting on MicroFactory’s journey, the startup made significant strides with its successful funding round and the innovative design of its robotic system, which prioritized affordability and safety. The strategic focus on accessibility for smaller businesses carved a unique niche in a competitive field, while early demonstrations proved the practical value of bringing manufacturing back onshore. As the company laid the groundwork for widespread automation, its vision of deploying millions of robots worldwide offered a glimpse into a future where manual labor was redefined. Moving forward, stakeholders across industries should consider how such technologies could integrate into existing systems, exploring partnerships or pilot programs to test scalability. The path ahead involves not just technological refinement but also addressing regulatory and workforce implications, ensuring that this wave of automation enhances rather than displaces human potential in manufacturing ecosystems.