Every single gram shaved from an aircraft component translates into thousands of dollars in fuel savings over its operational lifespan, a compelling economic reality driving the aerospace industry toward revolutionary manufacturing. As designers pursue ever-lighter and more efficient aircraft, 3D printing has emerged as a technology with unparalleled potential to create these next-generation parts. Yet, for an industry built on absolute certainty, this powerful tool is held back by one fundamental barrier: a lack of standardized, verifiable trust in its output.

The Billion Dollar Question of Aircraft Weight

The aerospace industry’s obsession with weight is not arbitrary; it is a core principle of engineering and economics. Minor weight reductions, when scaled across a fleet of aircraft and decades of service, result in monumental savings in fuel consumption and a significant decrease in carbon emissions. This relentless pursuit of optimization has pushed traditional manufacturing methods like milling and casting to their absolute limits, where further gains are increasingly difficult and costly to achieve.

Additive manufacturing, or 3D printing, offers a way to break through this plateau. It enables the creation of intricate, organically shaped components with internal lattices and consolidated assemblies—designs that are not only lighter but often stronger than their traditionally made counterparts. However, realizing this potential requires more than just innovative designs; it demands a guarantee of quality that can withstand the extreme stresses of flight.

Bridging the Divide Between Potential and Proven Reliability

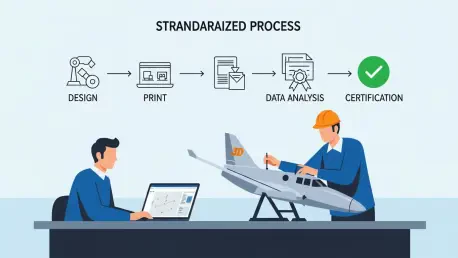

While the promise of additive manufacturing is immense, its adoption in critical aerospace applications has been cautious. The central challenge lies in the gap between the technology’s potential and the industry’s non-negotiable requirement for proven reliability. For a part to be flight-certified, manufacturers must be able to prove that the tenth, hundredth, and thousandth component produced is identical in its structural integrity and performance to the very first.

This is where the process variability of 3D printing becomes a hurdle. Factors like minute changes in laser power, powder quality, or thermal conditions can introduce microscopic defects that compromise a part’s integrity. Without a standardized framework to monitor, control, and verify every step of the manufacturing process, regulators and manufacturers cannot have the confidence needed to widely adopt these revolutionary components for safety-critical functions.

The SONRISA Project as a Blueprint for Trust

To address this challenge head-on, a consortium of industry leaders including Liebherr-Aerospace, Boeing, and MTU Aero Engines has initiated the SONRISA project. This collaborative effort aims to construct the very bridge of trust that the industry needs by developing a digitized and repeatable quality assurance system for a key 3D printing process: Laser Beam Powder Bed Fusion (PBF-LB). The project’s strategy is built on a foundation of comprehensive data-driven oversight.

The initiative focuses on integrating in-situ monitoring, which collects data during the printing process, with ex-situ analysis conducted after the part is complete. This holistic data is then subjected to rigorous statistical process control to ensure the PBF-LB method is stable and its results are consistently predictable. A robust data infrastructure underpins the entire framework, designed to manage and interpret the massive volumes of information generated, turning raw numbers into actionable proof of quality.

Turning Raw Data into Certified Aerospace Parts

At the heart of this digital transformation is the Belgian AM specialist Materialise, tasked with developing the intelligent software core of the quality assurance system. Their work involves creating a sophisticated concept for the automated, data-driven acceptance of finished aerospace components, effectively removing human subjectivity from the final quality assessment.

This is achieved by fusing and analyzing a multitude of diverse data streams—from thermal camera readings and layer-by-layer build images to post-production CT scans of a component’s internal structure. Advanced algorithms will assess this combined data to render a reliable go/no-go decision on a part’s airworthiness. Furthermore, Materialise is developing virtual feasibility testing workflows that allow engineers to validate a part’s manufacturability early in the design phase, drastically reducing development time and material waste.

Defining the Payoff for a Standardized Future

The ultimate vision for the SONRISA project extends beyond simply creating a new quality control process; it seeks to redefine the economics and certification pathways for aerospace manufacturing. By establishing this standardized, data-backed framework, the consortium’s efforts provided international regulatory bodies like the EASA and FAA with the verifiable evidence needed to accelerate the certification of 3D-printed parts.

This streamlined approval process significantly reduced the immense costs, time, and energy consumption traditionally associated with qualifying new components for flight. More importantly, the successful framework established by the project generated foundational confidence across the industry. It proved that additive manufacturing could consistently deliver the high-quality, dependable components that aviation demands, unlocking its full potential to shape a lighter and more sustainable future in the skies.