In a world where manufacturing demands are shifting toward speed, customization, and sustainability, a Silicon Valley innovator has taken a significant step forward with a major financial boost. Carbon, a trailblazer in additive manufacturing, has recently raised $60 million in funding, marking a transformative moment for the 3D printing industry. This substantial investment, backed by heavyweights such as Sequoia Capital, Silver Lake, adidas, Baillie Gifford, Madrone, and Northgate, signals strong confidence in Carbon’s ability to redefine how products are designed and produced. The focus of this funding is to ramp up production capabilities and steer the company toward cash flow-positive status, solidifying its role as a leader in digital manufacturing. With industries increasingly seeking flexible and localized production solutions, Carbon’s approach offers a timely answer to long-standing challenges in scaling high-performance polymer components. This development not only highlights the company’s potential but also underscores a broader shift in how global markets approach industrial innovation.

Driving Innovation in Additive Manufacturing

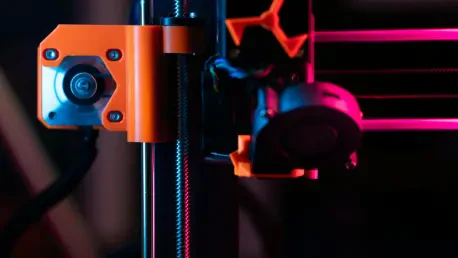

Carbon’s mission centers on overcoming the historical hurdles of additive manufacturing by enabling large-scale production of high-quality polymer parts. Since its inception, the company has built a comprehensive platform that combines cutting-edge hardware, over a dozen proprietary materials, and advanced software solutions. This integrated system allows for the creation of end-use parts across a variety of sectors, from consumer goods to medical applications. The versatility of Carbon’s technology addresses a critical need for efficient production methods that can adapt to specific industry demands. As markets prioritize resilience through localized manufacturing, Carbon’s innovations stand out as a catalyst for change, offering tools that empower businesses to meet modern challenges with agility. The recent funding will further enhance these capabilities, ensuring that the company can scale operations to match growing global interest in sustainable and customizable production.

The impact of Carbon’s technology is evident in its ability to serve diverse industries with tailored solutions. Unlike traditional manufacturing, which often struggles with flexibility, Carbon’s platform facilitates rapid prototyping and production at scale, reducing both time and cost. This is particularly significant in a landscape where supply chain disruptions have exposed vulnerabilities in conventional systems. By focusing on digital manufacturing, Carbon provides a pathway for companies to localize their production, minimizing reliance on overseas supply chains. The $60 million investment will accelerate these efforts, allowing Carbon to expand its reach and refine its offerings. Moreover, the company’s commitment to developing proprietary materials ensures that the parts produced meet stringent performance standards, setting a benchmark for quality in the additive manufacturing space. This strategic focus positions Carbon as a key player in shaping the future of industrial production.

Transforming Industries through Strategic Partnerships

One of Carbon’s standout achievements lies in its collaborations with industry giants, which demonstrate the real-world applications of its technology. A notable partnership with adidas, spanning several years, has led to the production of millions of components, including the innovative Climacool footwear line designed for optimal comfort and airflow. Beyond consumer goods, Carbon’s influence extends to sports protection, where its technology has been pivotal in creating football helmets for brands like Riddell, consistently topping safety rankings in NFL and NFLPA tests. The cycling industry also benefits, with high-performance saddles from brands such as Fizik, Selle Italia, and Trek being used by top athletes in major competitions. These partnerships highlight how Carbon’s solutions are not just theoretical but deliver measurable outcomes across varied markets, reinforcing the value of its platform.

Another critical area of impact is the dental sector, where Carbon has become a leading force in producing customized parts on a massive scale. Weekly outputs of millions of dental components showcase the company’s capacity to meet high-volume demands with precision. Collaborations, such as the one with Keystone Industries for flexible partial dentures, further illustrate Carbon’s role in driving innovation in medical applications. These achievements are underpinned by a robust network of partners who trust Carbon’s technology to deliver cutting-edge solutions. The recent $60 million funding round will enable deeper customer relationships, allowing Carbon to expand its footprint in existing markets while exploring new opportunities. By bridging the gap between advanced technology and practical application, Carbon continues to set itself apart as a transformative force in manufacturing, catering to evolving needs with unmatched expertise.

Shaping the Future of Digital Manufacturing

Stakeholder confidence in Carbon’s vision is reflected in the optimistic outlook shared by key figures associated with the company. Co-founder Phil DeSimone has emphasized the strength of Carbon’s portfolio and its trusted partnerships, noting that the new funding opens doors to broader possibilities in digital manufacturing. Similarly, Jim Goetz of Sequoia Capital has praised the unique blend of print technology, proprietary resins, and design expertise that positions Carbon at the forefront of industry innovation. This alignment of vision and resources underscores a collective belief in Carbon’s potential to redefine production standards in the United States and beyond. The investment serves as a catalyst for accelerating momentum, ensuring that Carbon can meet rising demand while maintaining its commitment to quality and sustainability in manufacturing processes.

Looking back, the journey following the $60 million funding round marked a defining chapter for Carbon as it tackled historical challenges in additive manufacturing with groundbreaking solutions. The investment enabled the company to scale production and strengthen ties with key industries, from sports to medical applications. Reflecting on this period, it became clear that Carbon had laid a solid foundation for future growth. Moving forward, the focus should be on leveraging this momentum to explore untapped markets and refine technologies that address emerging needs. Stakeholders and industry observers alike should watch how Carbon continues to innovate, potentially setting new benchmarks for localized, technology-driven production. The path ahead offers opportunities to build on past successes, ensuring that digital manufacturing evolves to meet global demands with efficiency and foresight.