In an era where manufacturing faces relentless pressure to adapt to rapid product changes and complex tasks, a groundbreaking solution has emerged to redefine automation on factory floors. CarbonSix Inc., based in Wilmington, Delaware, has introduced an innovative toolkit that promises to transform how industries approach robotic learning and efficiency. Designed for sectors like electronics, automotive components, and food and beverage, this new system leverages artificial intelligence to enable robots to tackle non-standardized tasks with unprecedented adaptability. By addressing the historical challenges of automation in unstructured environments, where frequent shifts in production demands have often outpaced traditional robotic capabilities, CarbonSix offers a glimpse into a future of seamless integration between human expertise and machine precision. This development marks a significant milestone in physical AI for manufacturing, sparking curiosity about how such technology could reshape industrial processes across the globe.

Revolutionizing Automation with Imitation Learning

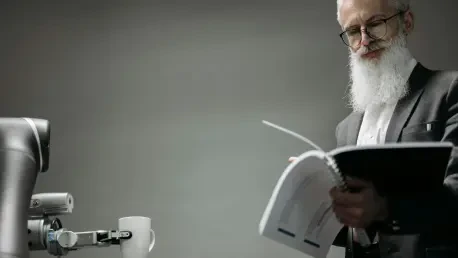

The cornerstone of CarbonSix’s latest offering lies in its adoption of imitation learning, a cutting-edge method that allows robots to mimic human actions directly through demonstrations. Unlike conventional programming, which often falters when faced with non-routine or intricate processes, this approach equips robots to handle delicate operations such as film attachment, assembly, and cable fastening with remarkable finesse. The toolkit integrates sophisticated AI algorithms, precision grippers, and sensor modules to facilitate adaptive recognition, enabling the system to learn from repeated human-guided tasks. Manufacturers can create a robust training dataset by demonstrating actions, with the system capable of generating actionable models in under a day for certain applications. This rapid learning curve reduces downtime and eliminates the need for extensive technical expertise, positioning the technology as a game-changer for industries seeking to streamline complex workflows without sacrificing flexibility or accuracy.

Beyond the technical innovation, the practical implications of this imitation-based system are profound for factory environments characterized by high variability. The ability to filter and review training data ensures that the resulting robotic skills are both efficient and reliable, tailored to specific operational needs. Tasks that once required constant human intervention or cumbersome system adjustments can now be automated with minimal setup, freeing up valuable manpower for strategic roles. CarbonSix’s focus on user-friendly teaching tools further democratizes access to advanced robotics, allowing even non-specialized staff to contribute to the training process. Early feedback from industry stakeholders highlights a growing recognition of this toolkit as a scalable solution, particularly in sectors where adaptability is paramount. As manufacturing continues to evolve, such advancements underscore a shift toward smarter systems that bridge the gap between human intuition and robotic execution.

Industry Impact and Market Potential

A notable aspect of CarbonSix’s innovation is its status as a pioneering commercial solution for industrial robot AI rooted in imitation learning, setting it apart from existing automation technologies. Designed to address the persistent barriers to full automation, the toolkit offers a practical answer for manufacturers grappling with frequent product changes and unstructured tasks. Co-CEO Jehyuk Kim, who spearheaded the development, has emphasized its versatility across diverse industries, from batteries to materials processing. Initial market interest, evidenced by sales inquiries and proof-of-concept projects with leading global manufacturers, suggests a strong demand for such flexible systems. This traction reflects a broader industry trend toward integrating AI to overcome the limitations of traditional robotics, paving the way for more responsive and efficient production lines that can adapt on the fly to new challenges without requiring constant recalibration.

Equally compelling is the expertise behind this technological leap, with CarbonSix’s leadership team bringing a wealth of knowledge from prestigious institutions like MIT and Yale, as well as proven industry experience. This credibility bolsters confidence in the toolkit’s potential to deliver on its promises, particularly as companies seek reliable solutions to enhance operational efficiency. The system’s ability to eliminate the need for ongoing manual configurations positions it as a cost-effective alternative to conventional methods, appealing to businesses aiming to balance innovation with practicality. As automation becomes increasingly critical in competitive markets, the early adoption and pilot projects signal a readiness among manufacturers to embrace AI-driven tools. This momentum hints at a transformative impact, where the fusion of advanced software and intuitive hardware could redefine standards for productivity and adaptability in industrial settings.

Shaping the Future of Manufacturing Efficiency

Reflecting on the strides made by CarbonSix, it becomes evident that their toolkit has already begun to address critical gaps in manufacturing automation through a novel approach to robotic learning. By enabling machines to learn directly from human demonstrations, the system has offered a scalable way to automate intricate tasks that once demanded significant human oversight. The integration of tailored AI and hardware has proven effective in enhancing precision and flexibility on factory floors, setting a new benchmark for industrial robotics.

Looking ahead, the focus shifts to actionable next steps for industries eager to capitalize on this innovation. Manufacturers are encouraged to explore pilot implementations to assess how such technology can integrate with existing workflows, while policymakers and industry leaders can consider frameworks to support wider adoption of AI-driven automation. The ongoing collaboration with global partners in proof-of-concept initiatives points to a future where adaptable robotic systems might become the norm, driving efficiency and redefining production capabilities across sectors.