The Carvera Air by Makera is a versatile desktop CNC (Computer Numerical Control) machine designed for hobbyists and small-scale manufacturers. This detailed article explores the machine’s features, setup process, software requirements, and practical applications. Through thorough analysis, key themes and consensus viewpoints are identified, providing a comprehensive understanding of the Carvera Air’s capabilities and potential challenges.

Introduction to the Carvera Air CNC Machine

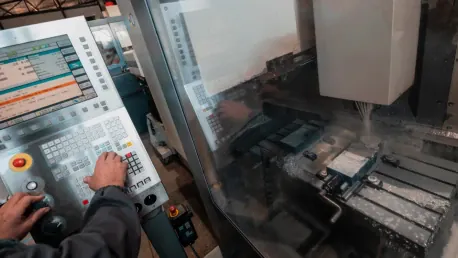

The Carvera Air is a compact and sophisticated CNC machine that can perform tasks typically carried out by large, industrial CNC machines but on a smaller scale. It uses a computer-guided system to control drills, lathes, laser cutters, engravers, and mills to create various intricate designs on different materials, including wood, metal, and plastic. This capability makes it ideal for hobbyists who want to produce professional-quality work at home and for small manufacturers who need a reliable and versatile machine for low-volume production.

Key Features of the Carvera Air

The Carvera Air boasts several key features that make it a standout in the desktop CNC market. First and foremost, its versatility allows it to handle a wide range of tasks, from routing to engraving and 3D carving. This makes it a highly adaptable machine suitable for various projects, from simple hobbyist endeavors to more complex manufacturing tasks. Furthermore, the user-friendly design includes a quick-change mechanism for tools and a slightly reduced build platform compared to its flagship counterpart, the Carvera. This ensures that users can quickly switch between different tools, minimizing downtime and maximizing productivity.

Another significant feature is the automatic probing, which creates a digital model of the workpiece surface for more accurate tooling. This feature not only enhances the precision of the machine but also reduces the margin for error, ensuring consistent and high-quality results. Additionally, the Carvera Air offers flexible control options through desktop applications or mobile apps via Wi-Fi or USB. This flexibility allows users to control the machine from various devices, making it more convenient to operate. The machine’s solid die-cast frame signals high-quality engineering, ensuring durability and reliability over long periods of use.

Setup and Assembly

Setting up the Carvera Air is relatively straightforward compared to other desktop CNC machines. Traditional CNC or 3D printers often require extensive tinkering with hex wrenches and assembling aluminum rails, but the Carvera Air simplifies this process significantly. Upon unboxing, users must install software on their computer and power on the machine. One initial hurdle may arise from setting the correct voltage (115 volts for American power mains), but once this is addressed, the machine is ready to connect to the Wi-Fi. This streamlined setup process minimizes the time and effort typically associated with assembling CNC machines, allowing users to focus on their projects more quickly.

Accessories and bits, such as bolts, clamps, and saws, are included and need to be organized, a task made manageable by the machine’s straightforward design. The included items ensure that users have all the necessary components to start their projects immediately. Additionally, the user-friendly design of the Carvera Air minimizes the need for extensive manual adjustments, further simplifying the setup process. This emphasis on ease of use makes the Carvera Air an attractive option for both beginners and experienced CNC users who appreciate a more hassle-free experience.

Software Integration

The Carvera Air’s control software, Carvera Air Controller, is available across several operating systems, including Windows, Mac, Linux, and Android, with a pending iOS version. Users intending to move beyond basic operations may need additional software for vector creation and 3D modeling, such as Inkscape, Autodesk Fusion, VCarve Desktop, and LightBurn. The process can be somewhat complex, involving multiple software applications to achieve a finished product: CAM (computer-aided manufacturing) software translates 3D models into toolpaths for CNC, a complicated task requiring familiarity with the machine’s specifications and capabilities.

Specifically noted is the absence of specific profiles for the Carvera Air initially, requiring users to modify existing profiles or await official releases. This can be a minor inconvenience for new users, but for experienced operators, modifying existing software profiles is a manageable task. The complexity of software integration highlights the need for users to have a basic understanding of CNC software and the various applications involved in creating toolpaths. Despite these challenges, the advanced capabilities and flexibility offered by the Carvera Air make the effort worthwhile, enabling users to achieve precise and intricate designs.

Practical Applications and Projects

Creating an LED Light

One of the first projects suitable for the Carvera Air is creating a desktop LED light with a touch switch that lights up a carving in clear acrylic. This project demonstrates the machine’s capability to handle various materials and produce precisely milled parts and printed circuit boards. The included PCB facility is particularly attractive for creating single- and double-sided solder-masked PCBs, a feature that hobbyists and small manufacturers will find particularly useful.

However, users might face challenges with inconsistent terminology and vague instructions within the provided manuals. This uncertainty can slow progress, particularly for new users unfamiliar with CNC milling. Despite these minor frustrations, the end product is likely rewarding and displays the machine’s multifunctionality. This project not only showcases the Carvera Air’s precision but also highlights its ability to execute complex designs that require intricate detailing and accurate milling.

Carving a Three-Axis Relief

The next project involves carving a 3D relief image into a board. It highlights the importance of using a vacuum to manage dust collection, as the milling process can be quite messy. This step shows the Carvera Air’s ability to handle material with precision, creating detailed reliefs once the waste material is properly cleaned off. The precision and accuracy required for this project demonstrate the Carvera Air’s capabilities, allowing users to produce professional-quality relief carvings.

For this project, users must consider the type of material being used and the appropriate milling tools to achieve the desired results. The Carvera Air’s versatility in handling different materials ensures that users can experiment with various types of boards, plastics, and more. By mastering the techniques involved in three-axis relief carving, users can expand their repertoire of CNC projects and achieve increasingly complex designs.

Fourth-Axis Projects

For advanced users, the rotary attachment or 4th-axis capability adds another layer of versatility, allowing the machine to function as a lathe. The setup may appear daunting initially, but the well-designed bolt patterns and the machine’s precision make the process manageable. The rotary module is particularly robust, reflecting the Carvera Air’s overall high build quality. Executing fourth-axis projects requires a good understanding of the machine’s capabilities and the additional software needed to design and execute these projects.

When starting with fourth-axis projects, initial attempts may result in the failure of the workpiece or inaccuracies in time estimation. Software updates and firmware improvements are essential to correct these issues, ensuring a smoother process and high-quality output. Users who invest time in mastering the fourth-axis capabilities will find a wealth of new applications and creative possibilities. Whether creating complex cylindrical designs or intricate lathe projects, the Carvera Air’s advanced features enable users to push the boundaries of desktop CNC machining.

Consensus Viewpoints and Trends

Ease of Use vs. Technical Expertise

The Carvera Air simplifies many aspects of CNC machining, making it more accessible than older models. However, it remains a tool best suited for users with some level of technical expertise and experience with CNC or 3D printing technology. While beginners can navigate the basic functions with ease, advanced projects and precise work require a deeper understanding of CNC operations.

The learning curve associated with using the Carvera Air is softened by its user-friendly design, but familiarity with multiple software tools is still necessary to fully exploit its capabilities. This highlights a balance between ease of use and the technical knowledge required, making the Carvera Air an excellent choice for those willing to invest time in learning the intricacies of CNC machining.

High-Quality Build

Across different reviews, there is a consensus on the machine’s solid construction and robust design. The die-cast frame and sturdy components give an impression of durability and reliability, essential for consistent performance in various tasks. This high-quality build ensures that the Carvera Air can withstand the rigors of regular use, making it a reliable tool for both hobbyists and small manufacturers.

The machine’s robust design also suggests a long lifespan, providing users with a sense of value and longevity. This quality construction is a significant selling point for the Carvera Air, as it promises sustained performance without frequent breakdowns or maintenance issues. This reliability is crucial for users who need a dependable machine for their creative and manufacturing projects.

Final Assessment

The Carvera Air by Makera is an adaptable desktop CNC (Computer Numerical Control) machine crafted for hobbyists and small-scale manufacturers. This in-depth examination highlights the machine’s features, setup process, software requirements, and practical applications. Offering an all-encompassing insight, the article identifies significant themes and gathers consensus viewpoints to shed light on the Carvera Air’s capabilities and potential hurdles.

The Carvera Air stands out for its user-friendly design and efficient operation. Its compact size makes it suitable for home workshops, while its powerful functionality meets various manufacturing needs. Setting up the machine is straightforward, tailored to beginners yet versatile enough for seasoned users.

When it comes to software, the Carvera Air is compatible with a range of CAD and CAM programs, providing flexibility in design and execution. Practical applications include engraving, cutting, and even 3D carving, enabling users to create intricate and precise pieces.

Despite its many strengths, users should be aware of potential challenges such as the learning curve associated with CNC programming and the need for regular maintenance to ensure long-term performance. Nonetheless, the Carvera Air by Makera offers a balanced mix of accessibility and advanced features, making it an appealing choice for those engaged in detailed production work on a smaller scale.