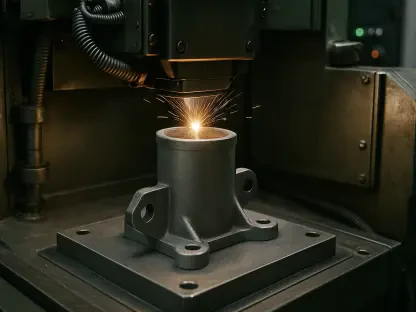

In an era where technology is reshaping industries at an unprecedented pace, a remarkable development has emerged from Hangzhou, China, where Guozi Robotics has unleashed nearly 200 advanced robots to fully automate excavator production at TZ Group’s cutting-edge factory. Often described as “steel giants building steel beasts,” this groundbreaking initiative highlights the transformative power of robotics and artificial intelligence (AI) in the construction-machinery sector. Far from being just a local achievement, this milestone reflects a broader shift toward smarter, more efficient manufacturing systems that minimize human intervention while maximizing precision. The implications of such automation extend across global industries, promising to redefine how heavy machinery is produced. As this technology takes root, it offers a compelling vision of a future where machines handle complex tasks with unparalleled accuracy, setting the stage for a deeper exploration of its impact on production, logistics, and the workforce.

Cutting-Edge Technology Driving Automation

The foundation of Guozi Robotics’ success lies in the sophisticated technology powering their robotic systems, which are designed to handle the rigors of heavy-duty manufacturing. These robots are equipped to manage high-mix production environments, seamlessly switching between diverse tasks without the delays typically caused by re-tooling. Integrated with advanced control and execution systems, they maintain a continuous flow of real-time data across the factory floor, ensuring every process is optimized for speed and accuracy. Contact-free power systems further enhance their efficiency by enabling uninterrupted operation, eliminating the need for frequent downtime. This technological synergy not only boosts productivity but also sets a new standard for what automation can achieve in industrial settings, pushing the boundaries of traditional manufacturing methods.

Equally impressive is the adaptability of these robotic systems to the complex demands of excavator production. Unlike conventional machinery that often requires extensive reconfiguration, Guozi’s robots demonstrate remarkable flexibility, tackling intricate assembly processes with precision. Their ability to coordinate multiple tasks simultaneously ensures that production lines remain fluid, even under high-pressure conditions. This level of innovation represents a significant leap forward, as it reduces errors and enhances output quality, delivering excavators that meet stringent industry standards. By integrating such advanced capabilities, Guozi Robotics showcases how technology can transform even the most labor-intensive sectors into models of efficiency, offering valuable insights into the potential for broader industrial applications.

Transforming Logistics with AI Innovation

Beyond the factory floor, Guozi Robotics is redefining logistics through the power of AI-driven systems that orchestrate operations with astonishing precision. Automated Guided Vehicles (AGVs) navigate the supply chain with centimeter-level accuracy, ensuring materials move from warehouse to workstation without a hitch. These systems dynamically manage storage and execute smart picking for a wide array of components, categorized by size and type, to streamline the entire process. By reducing bottlenecks and minimizing manual intervention, this approach creates a synchronized workflow that enhances visibility across the supply chain. The result is a dramatic improvement in operational speed, allowing industries to meet tight deadlines without compromising on accuracy or reliability.

Another critical aspect of this logistics revolution is the way it addresses the inefficiencies that have long plagued industrial supply chains. Traditional methods often rely heavily on human labor, leading to errors and delays that can disrupt production schedules. In contrast, Guozi’s AI systems anticipate needs in real-time, adjusting storage allocations and delivery routes to prevent shortages or overstocking. This proactive management not only cuts costs but also ensures that resources are utilized effectively, supporting a leaner and more responsive operation. As these technologies gain traction, they highlight the potential for automation to solve longstanding challenges in logistics, paving the way for more agile and resilient industrial ecosystems that can adapt to fluctuating demands.

Global Influence and Strategic Collaborations

Guozi Robotics’ impact is not confined to a single region; their innovations resonate across more than 20 countries, with over 1,000 customer installations worldwide. This expansive reach underscores the universal appeal of their automation solutions, which cater to a variety of industrial needs. Strategic partnerships with major corporations such as Staples, Zoomlion, XCMG, and Sany further amplify their influence, demonstrating the practical value of their technology in real-world applications. Some of these collaborations, spanning nearly a decade, reflect a deep trust in Guozi’s ability to deliver results, helping industries meet the escalating demand for automated solutions on a global scale.

The significance of these partnerships extends beyond mere numbers, illustrating how Guozi Robotics is shaping the future of manufacturing through collaborative innovation. By working closely with industry leaders, the company gains insights into diverse operational challenges, allowing for the refinement of their robotic systems to address specific needs. This synergy fosters the development of tailored solutions that enhance productivity across different sectors, from construction to logistics. Moreover, the global adoption of their technology signals a growing consensus on the necessity of automation to remain competitive in today’s fast-paced markets. As Guozi continues to expand its footprint, it plays a pivotal role in driving the worldwide transition toward smarter, more efficient industrial practices.

Navigating the Challenges of Automation

While the advantages of automation are clear, the rapid integration of robotics into industries raises important concerns that cannot be overlooked. One of the most pressing issues is the potential for job displacement, as machines take over tasks traditionally performed by human workers. This shift, while beneficial for efficiency and cost reduction, poses a risk to livelihoods, particularly in sectors heavily reliant on manual labor. Addressing this challenge requires a delicate balance, ensuring that technological progress does not come at the expense of workforce stability. Guozi Robotics’ advancements highlight the urgency of developing strategies to mitigate these impacts, prompting a broader discussion on the role of automation in society.

Equally important is the need for workforce adaptation to keep pace with these technological changes. As robots become integral to production and logistics, employees must acquire new skills to operate alongside advanced systems or transition to roles that complement automation. This necessitates investment in training programs and education to prepare workers for a transformed industrial landscape. The dual nature of Guozi’s innovation—offering immense potential for progress while presenting significant societal challenges—serves as a reminder that automation must be approached with foresight. By prioritizing reskilling initiatives and fostering dialogue between industry stakeholders, there is an opportunity to create a future where technology and human labor coexist harmoniously, ensuring sustainable growth for all.

Reflecting on a Robotic Revolution

Looking back, the deployment of nearly 200 robots by Guozi Robotics at TZ Group’s factory stood as a defining moment in the evolution of industrial automation. This ambitious project demonstrated how far technology has come in revolutionizing excavator production, achieving levels of efficiency and precision that were once unimaginable. Their AI-driven systems not only transformed manufacturing processes but also redefined logistics with unmatched accuracy, impacting industries across more than 20 countries. Strategic alliances with global giants further solidified their role as a leader in this space. Yet, the journey also illuminated critical challenges, particularly around job displacement and the need for workforce adaptation. Moving forward, the focus should shift to actionable solutions—investing in reskilling programs and fostering policies that balance technological advancement with social responsibility. This approach ensures that the benefits of automation are shared widely, shaping an industrial future that values both innovation and humanity.