The world of additive manufacturing, with its breakneck speed and single-button simplicity, often stands in stark contrast to the traditional, labor-intensive processes of subtractive manufacturing. For decades, turning a digital 3D model into a precision-milled metal component has remained a craft reliant on years of human expertise, where project timelines are measured in weeks, not hours. This frustrating reality is what confronted Theo Saville, a mechanical engineering graduate inspired by the rapid prototyping capabilities of 3D printers. Upon entering the professional world, the transition from producing plastic parts in 24 hours to being quoted ten weeks for complex metal components seemed utterly illogical. This led to a pivotal question posed in front of a Computer Numerical Control (CNC) machine: Why couldn’t this process be as automated and accessible as 3D printing? This query, born from a desire to bridge the efficiency gap between different manufacturing paradigms, became the foundational spark for a technological revolution in precision machining.

1. A Mission Forged in Frustration

The journey to simplify CNC machining began in earnest when Theo Saville met his co-founder, Chief Scientist Chris Emery, at a UK incubator program that pairs entrepreneurs. Both shared a background in additive manufacturing startups and a common frustration with the limitations of traditional subtractive methods. They immediately began speaking with manufacturers to understand the core bottlenecks and pain points of the industry. Armed with direct feedback and initial seed capital raised from family and friends, they established CloudNC. The mission they outlined in their original investor deck a decade ago has remained remarkably consistent: to empower CNC users to machine a component with just a few clicks and commands, rather than the hundreds of manual inputs typically required. The goal was to create a system where a relatively inexperienced operator could achieve the same high-quality results as a programmer with ten years of experience, effectively democratizing the production of precision metal parts and breaking down the barriers of esoteric knowledge.

This steadfast vision was not merely about creating a new tool but about fundamentally rethinking the entire workflow from design to finished part. The co-founders understood that the primary obstacle was the sheer complexity of CAM (Computer-Aided Manufacturing) programming, a process that had seen little fundamental change in decades. It remained a highly manual, repetitive, and error-prone task that depended heavily on the intuition and experience of the programmer. Their mission targeted this specific chokepoint, aiming to automate the decision-making process that programmers undertake for every single feature of a part. By translating the implicit knowledge of seasoned machinists into explicit, repeatable software logic, CloudNC set out to build a platform that could analyze a component’s geometry and autonomously generate an optimal, efficient, and reliable machining strategy. This would not only accelerate production but also address the growing skills gap in the manufacturing sector by amplifying the capabilities of existing talent.

2. The Long Road of Development

Achieving this ambitious goal proved to be an immense technological undertaking, far more complex than initially anticipated. The team quickly discovered that automating precision manufacturing was not a singular problem but a collection of thousands of disparate challenges. A key hurdle was the nearly infinite combination of potential solutions for machining any given part; choosing the right tools, toolpaths, speeds, and feeds involves a staggering number of variables. Furthermore, the physical environment of machining—with its intense forces, vibrations, and material variations—presented a chaotic and unpredictable system that the software had to model and control with precision. Overcoming these obstacles required years of dedicated development and the creation of a massive, proprietary codebase that could encapsulate the vast and nuanced knowledge required to solve each part of the complex puzzle, from geometry analysis to physics-based cutting simulations.

The development process was as practical as it was theoretical, with the company making the strategic decision to build and operate its own full-scale production factory. This facility was not just a laboratory for testing software builds; it became a real-world manufacturing business producing components for major industries. Operating their own machines day in and day out provided the engineering team with an invaluable, continuous feedback loop. They experienced the same pressures and challenges as their future customers, allowing them to refine the software based on tangible production data and real-world scenarios. This hands-on approach ensured that the technology was not developed in a vacuum but was forged in the fires of a working machine shop. This deep, practical understanding of the business of machinery would later become a cornerstone of the company’s credibility and a key differentiator in the market, proving that their solution was built by machinists, for machinists.

3. The Arrival of CAM Assist

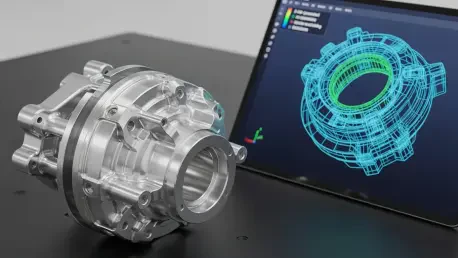

After eight years of intensive development and real-world validation, CloudNC launched CAM Assist in July 2023, marking a significant milestone in the quest for automated machining. The AI-powered software integrates directly into existing, popular CAM packages, acting as a co-pilot for CNC programmers. The workflow is designed for simplicity and speed. A user begins by uploading a 3D CAD model of their part directly within their familiar CAM environment. They then define the specific parameters of the job, such as the available cutting tools, the material being used, the workholding setup, and the specifications of the CNC machine. With the context established, the user activates CAM Assist. The system’s advanced AI and computational geometry algorithms then perform a comprehensive analysis of the entire part, meticulously measuring and mapping every feature, from simple holes and pockets to complex, free-form surfaces, to understand the most efficient way to machine it from a solid block.

This deep analysis enables the software to autonomously generate a complete and detailed machining plan in a matter of minutes. This plan includes not just the optimal toolpaths but also the ideal cutting directions, step-overs, and an initial set of recommended speeds and feeds. Critically, the process does not remove the human expert from the loop but rather empowers them. The programmer can review the entire strategy proposed by the AI, making any desired edits or adjustments to align with specific shop practices or unique job requirements. Once the user approves the plan, the software translates it into the final G-code that the CNC machine executes. By completing an estimated 80 percent of the CAM programming workload automatically, CAM Assist condenses hours or even days of tedious manual work into a few moments, representing a paradigm shift in manufacturing productivity and workflow efficiency.

4. Unlocking Human and Machine Potential

The implementation of CAM Assist offers manufacturers immediate and profound benefits that extend beyond mere time savings. By drastically reducing programming time, machine shops can achieve greater throughput from both their machines and their personnel. This heightened efficiency allows them to deliver parts to customers faster, respond to quote requests more quickly, and ultimately increase revenue and profitability. The technology also directly addresses one of the most pressing issues facing the modern manufacturing industry: the critical shortage of skilled CAD/CAM programmers. Instead of searching for increasingly scarce talent, companies can now significantly boost the productivity of their existing programmers. The software empowers a single programmer to manage the workload that previously might have required several, effectively multiplying the impact of their expertise across the shop floor.

Furthermore, the impact of this automation is felt on a human level, transforming the nature of the programmer’s role. By automating the monotonous and repetitive aspects of the job, such as defining routine toolpaths for standard features, the software liberates skilled professionals to focus on more complex, higher-value work. They can now dedicate their time to process optimization, tackling challenging geometries, improving surface finishes, or developing innovative manufacturing strategies that drive the business forward. This shift elevates their role from that of a technician performing basic calculations to that of a strategic problem-solver. As one user noted, the time saved by the software has tangible lifestyle benefits, allowing them to go home and have dinner with their children. This blend of enhanced business performance and improved quality of life underscores the transformative potential of applying AI thoughtfully within the manufacturing environment.

5. Evolving With User Control

CloudNC continued its rapid pace of innovation by launching CAM Assist 2.0 in September of the same year, a major upgrade that further refined the collaboration between human expertise and artificial intelligence. This new version retains the core speed and automation of the original while introducing critical elements of oversight, feedback, and shared intelligence. These additions were designed specifically to give machine shops the confidence and control needed to fully embrace AI in their high-stakes production environments. A key feature of the upgrade is the ability for users to see and influence the AI’s strategic decisions as they happen in real-time. Instead of presenting a finished plan as a “black box” solution, the new interface breaks out the AI’s decision-making stages, allowing programmers to assess the logic and intervene or adjust strategies on the fly.

This enhanced version now operates on a dedicated web-based CAM automation application that launches from within the user’s primary CAM package, providing a more robust and interactive experience. As the files are being computed, control over strategic editing is passed to the user, creating a truly collaborative programming environment. The platform continues to support both 3-axis and more complex 3+2 machining operations, ensuring its applicability to a wide range of parts. Recognizing the importance of seamless integration into existing workflows, CAM Assist 2.0 is available to all customers across industry-leading platforms, including Autodesk Fusion, Mastercam, and Siemens NX. The company has also signaled that further integrations with other major CAM systems are expected to be announced soon, demonstrating a clear commitment to making its revolutionary technology accessible to the broadest possible segment of the manufacturing industry.

6. Industry Validation and Global Reach

The response from the manufacturing industry to CAM Assist has been overwhelmingly positive, with many users expressing a sentiment that the technology feels like something that should have always existed. This intuitive fit within the modern machine shop has led to rapid adoption and a wave of gratitude from programmers who see it as a solution to long-standing workflow frustrations. A significant factor in this positive reception is CloudNC’s credibility as an industry insider. Because the company operates its own factory and produces metal parts for commercial clients, it is not viewed as an outsider software firm with no practical understanding of the industry’s needs. Instead, it is seen as a peer that has experienced the same challenges and has built a solution born from that shared experience. This deep domain knowledge, earned through running their own machinery business, has fostered a strong sense of trust and partnership with their customers.

As of this year, this trust has translated into significant market penetration, with CAM Assist now being used by over 1,000 machine shops and individual machinists worldwide. The software’s versatility has allowed it to be deployed across a host of demanding sectors, including the aerospace and defense industries, although its utility is universal for any company that needs to produce precision metal components. Interestingly, a large portion of the company’s current clientele is located in the United States. This strong presence is attributed not only to the technological innovation of American manufacturers but also to their cultural willingness to take a chance on new, disruptive technologies that promise a competitive edge. This global adoption serves as powerful validation that CloudNC’s solution is not merely a theoretical breakthrough but a practical, proven tool that is actively revolutionizing CNC machining on a worldwide scale.

7. A Vision Beyond Automation

Reflecting on the journey, the founders acknowledged the enormous challenges they had overcome during nine years of tackling what often seemed like impossible technology while simultaneously trying to raise the necessary capital to keep the business alive. The path was paved with technical hurdles and financial pressures, but the core mission had provided a constant direction. With the technology now proven and adopted in the market, the focus had shifted toward new challenges: aggressively entering new global markets and building the next, significantly larger iterations of the AI platform. The ultimate vision extended far beyond just automating basic CAM programming. It was hoped that in the near future, the practice of manually programming simple features would become entirely obsolete, allowing manufacturers to output four or five times more components per employee and per CAD program. The goal was to support much more complicated machine types and enable the efficient production of larger, more complex parts. As this future state materialized, it was believed they would be nearing mission-accomplished territory, though it was clear this was only the beginning of a much longer technological revolution.