The intricate dance of precision machinery is setting the stage for a monumental shift in global manufacturing, with the Computer Numerical Control (CNC) drilling machine market poised for extraordinary expansion. A recent market analysis projects a significant escalation from its 2024 valuation of US$4.35 billion to an impressive US$9.62 billion by 2031, charting a robust compound annual growth rate (CAGR) of 12.0%. These automated systems are the bedrock of modern industrial production, delivering unparalleled accuracy, repeatability, and speed in creating holes across a vast array of materials, from metals and plastics to advanced composites. Their integral role is felt across a spectrum of critical sectors, including automotive, aerospace, electronics, and heavy construction, where their ability to execute complex drilling patterns far surpasses the limitations of conventional manual techniques, cementing their status as an indispensable asset in the contemporary manufacturing landscape.

Catalysts for Unprecedented Growth

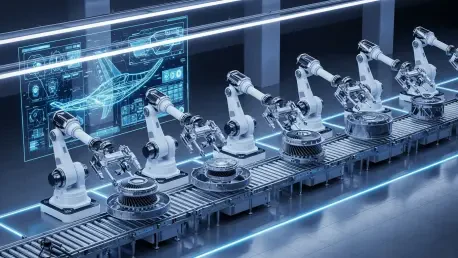

The relentless pursuit of precision and automation across the global manufacturing sector stands as a primary catalyst for the market’s upward trajectory. Industries worldwide are placing an ever-increasing emphasis on achieving exact manufacturing tolerances, ensuring unwavering product quality, and maintaining process repeatability. CNC drilling machines are central to this industrial evolution, as their computer-controlled operations drastically minimize the potential for human error, significantly boost output efficiency, and provide a level of precision that manual methods simply cannot replicate consistently. This paradigm shift is further accelerated by the widespread adoption of Industry 4.0 and smart manufacturing principles. The integration of digital technologies, such as the Internet of Things (IoT) and Artificial Intelligence (AI), into these machines is unlocking advanced functionalities like predictive maintenance, which optimizes operational uptime and reduces costly breakdowns, thereby solidifying their value proposition in a highly competitive market.

Further fueling this expansion is the robust growth within key industrial sectors that heavily rely on high-precision components. The automotive industry, in particular, is a formidable demand driver, especially with the global pivot toward electric vehicles (EVs). The fabrication of critical EV components, including battery casings, motor housings, and sophisticated powertrain systems, requires the high-accuracy drilling capabilities offered by advanced multi-axis and high-speed CNC systems. Similarly, the aerospace and renewable energy sectors depend on these machines to produce complex, lightweight, and high-strength parts that are essential for their advanced applications. The intricate designs and stringent material requirements in these fields create a continuous demand for sophisticated CNC drilling technology, underscoring the market’s deep integration with industries at the forefront of innovation and sustainability, ensuring a steady stream of demand for years to come.

Navigating Technological Frontiers and Economic Headwinds

Next-generation CNC drilling machines are being engineered with state-of-the-art technologies designed to address the complex demands of modern manufacturing. A key innovation is the seamless integration of AI-driven programming, a feature that significantly reduces machine setup times and minimizes the likelihood of operational errors. This makes the technology more accessible and user-friendly, even for skilled operators transitioning to smarter manufacturing environments. Another transformative feature is the adoption of a modular design philosophy, which allows these machines to be easily configured and adapted for a diverse range of applications. This inherent versatility is crucial for industries with fluctuating production needs, spanning sectors from shipping and automotive to electronics and equipment manufacturing. Moreover, these machines are being built with enhanced durability and ergonomic safeguards to ensure longevity and protect operator well-being, while optimized power usage aligns with global green manufacturing initiatives, helping to lower operational costs without compromising performance.

Despite the highly positive growth outlook, the market must navigate several significant challenges that could potentially restrain its expansion. The substantial initial cost of acquiring and maintaining advanced CNC drilling equipment represents a formidable barrier to entry, particularly for small and medium-sized enterprises (SMEs) operating with limited financial resources. Furthermore, a persistent shortage of skilled labor capable of operating, programming, and servicing this sophisticated machinery serves as a notable constraint on market growth. The complexity of modern CNC technology demands a specialized skill set that is not always readily available in the workforce, creating a gap between technological capability and practical implementation. The market also remains susceptible to external economic factors, including fluctuations in the prices of raw materials and disruptions within the global supply chain, which can negatively impact manufacturing operations, affecting both production costs and delivery timelines for machine manufacturers and end-users alike.

A Global Perspective on Market Dynamics

The Asia-Pacific (APAC) region has firmly established itself as the dominant force in the global CNC drilling machine market and is projected to exhibit the highest growth rates through 2031. Its leadership is largely attributed to the presence of thriving manufacturing hubs in countries like China, India, and Japan. These nations host powerful automotive and electronics sectors that generate substantial and continuous demand for advanced CNC machinery. The region’s ongoing industrialization, coupled with significant government investment in manufacturing infrastructure, further solidifies its position as the primary engine of global market growth. As these economies continue to expand and upgrade their production capabilities, the demand for high-precision, automated drilling solutions is expected to surge, reinforcing APAC’s pivotal role in shaping the future of the industry.

Beyond the dominant Asia-Pacific market, other regions exhibit unique dynamics that contribute to the global landscape. In North America, the market is sustained by strong and consistent demand from the aerospace and advanced equipment manufacturing industries, which require cutting-edge technology for their highly specialized applications. A notable trend in this region is the increasing adoption of multi-spindle CNC drilling machines to enhance productivity and efficiency. The European market, meanwhile, is heavily influenced by stringent efficiency and quality standards, which drive the uptake of advanced CNC machines in the shipping and heavy machinery sectors. There is also a discernible shift toward sustainable and energy-efficient machine designs in Europe, reflecting the continent’s strong commitment to environmental responsibility. Concurrently, emerging economies in Latin America and the Middle East are presenting new growth opportunities, with rising investments in infrastructure projects creating niche markets for CNC drilling machines that balance high performance with affordability.

The Future Trajectory of Precision Manufacturing

The comprehensive analysis concluded that the CNC drilling machine market was firmly on a path of strong and sustained growth. This trajectory was overwhelmingly driven by the convergence of automation, precision manufacturing, and the broader digitalization of industry. As manufacturers worldwide navigated post-pandemic economic recoveries, these machines were identified as essential tools for fostering greater agility and enhancing competitive positioning. The findings highlighted their capacity to unlock critical efficiencies across the entire production lifecycle, from enabling rapid prototyping in the fast-paced electronics sector to supporting high-volume mass production in the automotive industry. While the Asia-Pacific region was expected to maintain its market dominance, the study also underscored how technological infusions in North America and a focused push toward sustainability in Europe would contribute to a more diversified and dynamic global market landscape for the foreseeable future.