The Computer Numerical Control (CNC) machine market is driving forward with impressive technological advancements, fostering an environment ripe for growth and innovation. Known for its vital role in modern manufacturing, the CNC machine market is a cornerstone in industries like automotive, aerospace, and electronics. This market’s capacity to automate intricate machining processes with remarkable precision ensures its indispensability. Over the years, CNC machines have evolved from basic automated tools to sophisticated, integrated systems that significantly minimize errors and reduce production times, garnering enhanced demand across various sectors.

Anticipated growth in the CNC machine market is notable, with estimates suggesting a rise from USD 71.03 billion in 2023 to USD 100.0 billion by 2032. A consistent compound annual growth rate of approximately 3.88% is expected for the period between 2025 and 2032. The market encompasses a variety of equipment types, such as milling machines, lathes, laser cutters, and grinders, each leveraging computerized controls to optimize efficiency and precision. These machines’ utility spans multiple industries, offering the twin benefits of high-quality manufacturing and the capability for mass customization, factors that are crucial for current and future industrial applications.

Influence of Automation and Precision in CNC Market

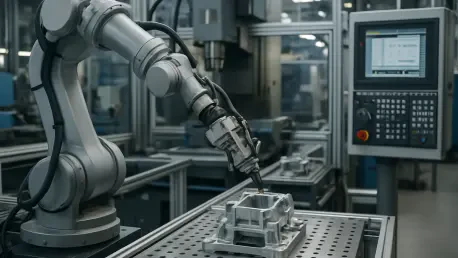

Automation and the quest for precision are pivotal trends shaping the current CNC market. The integration of automation has transformed manufacturing paradigms, allowing for smoother operations, enhanced productivity, and significant reductions in the time required for production. Technological innovations, such as multi-axis machining and integration with the Internet of Things (IoT), have further propelled the market forward. By enabling real-time monitoring, predictive maintenance, and remote diagnostics, these technological strides help companies achieve unprecedented operational efficiency.

The market players understanding these dynamics include giants like DMG Mori, Mazak, Siemens, and Okuma, among others. These players are at the forefront of bringing about innovative solutions that respond to increasing demands for precision engineering and technology integration. Companies are leaning towards sustainable manufacturing methods, focusing on energy-efficient machinery that minimizes waste, a crucial step that not only meets environmental standards but also optimizes resource use. This approach aligns with global trends towards eco-conscious manufacturing practices, further reinforcing the importance of precision and automation in the industry’s growth.

Drivers of CNC Market Expansion

One of the key drivers of the CNC market expansion is the escalating demand for automated manufacturing solutions, which offer increased productivity while reducing labor dependency and costs. This is particularly relevant in regions experiencing labor shortages and where the availability of skilled operators remains a challenge. Industries like automotive and aerospace, which require high precision and the ability to work with complex geometries, are significant beneficiaries of CNC machines. In sectors such as consumer electronics and medical device manufacturing, the trend of mass customization has propelled demand for these advanced manufacturing technologies, highlighting their transformative impact.

Government initiatives also play a pivotal role by promoting smart manufacturing and digital transformations, especially in emerging economies. These initiatives foster a conducive environment for evolution within the CNC market, paving the way for growth. As industries increasingly adopt Industry 4.0 technologies like IoT, AI, and cloud computing, the capabilities of CNC machines continue to expand. The adoption of hybrid manufacturing solutions, which merge traditional CNC with modern techniques like 3D printing, provides manufacturers with expanded design flexibility and cost-saving opportunities—a testament to the sector’s vibrant future.

Innovation and Challenges in CNC Technology

At the core of the market’s progress is constant innovation. The development of multi-axis and hybrid CNC systems, which combine additive and subtractive manufacturing, has revolutionized the capabilities of CNC machines. The incorporation of artificial intelligence and IoT into these systems fosters intelligent automation, enabling sophisticated functionalities such as predictive maintenance and advanced data analytics. Through these enhancements, CNC operators can mitigate downtime, refine machine efficiency, and broaden the spectrum of CNC applications.

Despite numerous opportunities, challenges persist within the CNC sector. The initial high cost of investment in CNC machinery is a barrier for small to medium-sized enterprises. Moreover, the need for skilled operators proficient in handling complex CNC systems remains a critical issue. Fluctuations in the economic climate, volatile raw material prices, and disruptions within the supply chain add layers of difficulty, affecting production and distribution timelines. As CNC machines increasingly adopt digital integrations, cybersecurity also becomes a pressing concern, emphasizing the need for robust security measures to protect digital assets and sensitive production data.

Future Trajectories and Strategic Directions

The Computer Numerical Control (CNC) machine market is advancing rapidly, heralding a new era of technological innovation and expansion. As a crucial component in modern manufacturing, particularly in sectors like automotive, aerospace, and electronics, CNC machines automate complex machining tasks with exceptional accuracy, establishing their essential role in these industries. Over time, CNC technology has transitioned from simple automated tools to advanced systems that significantly reduce errors and production times, leading to increased demand across various fields.

Projections indicate significant growth for the CNC machine market, with the valuation expected to climb from USD 71.03 billion in 2023 to USD 100.0 billion by 2032. Anticipated to maintain a steady compound annual growth rate of about 3.88% from 2025 to 2032, the market includes diverse equipment types like milling machines, lathes, laser cutters, and grinders. These machines utilize computerized controls to enhance both efficiency and precision, vital for high-quality production and mass customization, key drivers in contemporary and future industrial settings.