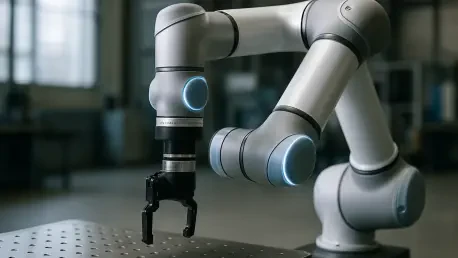

The rise of collaborative robots, or cobots, is fundamentally reshaping the modern factory floor by enabling automation systems to work directly alongside human employees, a significant departure from the caged, isolated industrial robots of the past. This evolution is propelled by the manufacturing industry’s relentless pursuit of greater flexibility and the capacity for rapid operational reconfiguration to meet fluctuating market demands. However, this intimate partnership between human and machine introduces a unique set of engineering challenges that go far beyond software and safety protocols. Cobots are frequently deployed in precision-critical applications, such as intricate assembly and meticulous quality control, where even the slightest deviation can compromise the final product. The dynamic and often unpredictable nature of these collaborative environments, characterized by constant human interaction, variable workflows, and frequent start-stop cycles, imposes immense and repeated stress on the robot’s physical components, threatening the very consistency they are designed to provide.

The Unseen Stresses of Collaboration

The operational environment for a cobot is fundamentally different from that of a traditional industrial robot, which performs highly repetitive tasks in a controlled, isolated cell. In a collaborative workspace, the workflow is fluid, and the robot’s movements are subject to constant micro-adjustments and interruptions. This variability is a primary source of mechanical stress that can lead to a gradual, almost imperceptible degradation of the cobot’s performance over time. Factors such as localized heat generation within joints during continuous operation and the cumulative effect of thousands of small, corrective motions can introduce minor material instabilities. These might manifest as thermal expansion in a structural component or minute wear on a critical surface. While individually insignificant, these deviations accumulate, eventually resulting in a tangible loss of accuracy. This performance drift necessitates more frequent recalibration, introduces the risk of unplanned downtime, and ultimately undermines the economic benefits of automation. For human-robot teams to function as a cohesive and productive unit, the cobot must deliver predictable and repeatable motion under the messy, real-world conditions of the factory floor.

The consequences of this physical degradation extend beyond simple performance metrics, directly impacting the entire manufacturing ecosystem. A cobot that loses its positional accuracy can introduce subtle defects into products, leading to costly rework or, in the worst-case scenario, customer returns and damage to brand reputation. Furthermore, the need for constant human intervention to recalibrate or troubleshoot a drifting system negates the efficiency gains automation is meant to deliver. Instead of focusing on higher-level process improvements, skilled technicians find themselves tied up with routine maintenance, effectively treating the symptoms rather than the root cause of the instability. This cycle of performance decay and reactive maintenance creates a bottleneck in production and introduces an element of unpredictability into what should be a highly controlled process. Therefore, ensuring the long-term physical integrity of the cobot is not just a matter of technical refinement but a core requirement for achieving a reliable and profitable manufacturing operation.

Material Science as the Cornerstone of Reliability

To counteract the inherent challenges of physical instability, a significant trend in cobot design is the strategic use of advanced materials for precision-critical components. The focus is shifting toward materials that offer superior dimensional stability under a wide range of thermal and mechanical stresses. Advanced ceramics, particularly alumina, have emerged as a leading solution due to their exceptional physical properties. With an extremely low coefficient of thermal expansion, alumina components are far less susceptible to changes in shape or size caused by temperature fluctuations common in industrial settings. This property is crucial for maintaining the geometric integrity of the robot’s structure. Furthermore, alumina boasts high resistance to wear and excellent electrical insulation, making it ideal for components like structural rods, alignment elements within joints, and interfaces for sensitive sensors. By integrating these stable materials, engineers can create a robust physical foundation that ensures the cobot’s motion paths remain consistent and its sensor positioning remains reliable over millions of operational cycles.

This focus on material science directly enhances both the safety and the overall efficiency of the human-robot team. A cobot’s sophisticated safety mechanisms, which rely on a network of sensors and force-limiting controls to prevent harm to human workers, operate on the assumption that the robot’s physical behavior perfectly matches its software models. If structural components warp, shift, or wear down, these fundamental assumptions can become invalid, potentially narrowing safety margins and creating unforeseen risks. By ensuring the robot’s physical structure remains predictable, stable materials indirectly bolster its safety systems. In terms of efficiency, the use of robust and wear-resistant components drastically reduces the need for frequent maintenance and minimizes calibration drift. This allows production teams to achieve longer, uninterrupted run times and dedicate their resources to optimizing workflows rather than constantly adjusting and repairing the automation equipment, leading to a more streamlined and productive manufacturing environment.

The Foundation of True Automation Intelligence

The journey toward truly smart manufacturing revealed that the future of production would rely heavily on the synergy between human creativity and robotic precision, especially for handling customized, short-run orders. The ultimate success of these integrated teams depended not just on sophisticated algorithms but on a design philosophy that prioritized the physical integrity of the machine from the outset. It became clear that advanced digital controls could only achieve their full potential when they were built upon a foundation of exceptional physical stability and meticulous engineering. This holistic approach, where material science was considered a pillar of the design process, was what ultimately enabled cobots to deliver the consistent, reliable, and safe performance required to transform the factory floor. True automation intelligence, it was found, emerged only when the digital brain and the physical body were in perfect, unwavering alignment.