For years, the immense potential of lightweight, high-strength reactive metals in additive manufacturing has been shadowed by the inherent difficulty and danger of processing them, relegating many advanced alloys to the realm of research rather than production. The very properties that make materials like magnesium desirable for aerospace and defense applications—their low density and high reactivity—also make them notoriously unstable and challenging to print using conventional laser powder bed fusion (LPBF) methods. This has created a significant bottleneck, preventing critical industries from fully leveraging these next-generation materials. A recent development, however, suggests a breakthrough may be at hand. Precision Additive has officially entered the market with its PA-300 system, a metal additive manufacturing platform designed not just to print these difficult alloys but to do so with unprecedented speed and consistency, driven by a sophisticated artificial intelligence core that promises to tame the volatility of reactive metal printing once and for all.

The Fusion of Speed and Intelligent Control

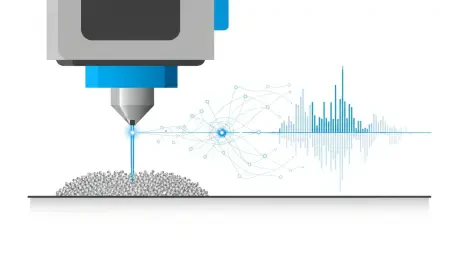

At the heart of the PA-300 system is a powerful synthesis of proprietary hardware and advanced software designed to overcome the traditional trade-offs between speed, quality, and material compatibility. The machine is equipped with a unique SSLM laser, an innovation that enables build speeds up to ten times faster than some competing LPBF systems, directly addressing the need for higher throughput in production environments. However, speed without precision is of little value, especially when working with temperamental materials. This is where the system’s core intelligence comes into play. Developed in collaboration with NVIDIA, a state-of-the-art, AI-based control architecture provides constant, real-time monitoring of the entire build process. This embedded AI actively watches for any deviations from the optimal parameters, making immediate adjustments on the fly to correct for inconsistencies before they become defects. This entire process is governed by the Precision Additive Qualification (PAQ) framework, a data-driven methodology that ensures every part is produced with consistent, repeatable quality, build after build.

From Laboratory Challenge to Production Reality

The launch of a system capable of reliably processing highly reactive materials marked a significant turning point for specialized manufacturing sectors. It directly addressed the long-standing gap between the theoretical advantages of alloys like magnesium, tungsten, and copper and the practical ability to fabricate them into complex, functional components. This technological advancement unlocked new design and application possibilities previously considered impractical for U.S.-based production in defense, aerospace, energy, and medical fields. The system’s proficiency was not merely a result of advanced hardware and software; it was built upon a foundation of deep domain expertise. Key personnel with extensive backgrounds in additive manufacturing and the application of magnesium alloys for demanding space and defense programs brought invaluable experience to the platform’s development. Ultimately, the introduction of AI-driven, real-time process control for reactive metals transformed what had been an unpredictable and highly specialized craft into a qualified, data-backed manufacturing method, paving the way for a new class of high-performance parts.