The manufacturing sector stands at a critical crossroads where embracing digital transformation has evolved from a strategic advantage to an absolute necessity for survival in a hyper-competitive global market, demanding swift adaptation to meet modern challenges. As technology accelerates at a breakneck pace, manufacturers—particularly small and medium-sized enterprises (SMEs) in regions like India—must adapt quickly to satisfy evolving customer expectations for speed, customization, and sustainability. The harsh reality is that clinging to traditional methods risks obsolescence, as competitors leveraging digital tools gain significant ground. This article explores the vital role of digital innovation in reshaping manufacturing, examining the urgent need for adoption, the barriers SMEs face, and the transformative opportunities presented by cutting-edge technologies. By analyzing real-world implications and emerging trends, the discussion aims to illuminate a path forward for manufacturers striving to secure their place in an increasingly digital landscape, ensuring they not only survive but thrive amid rapid industry evolution.

Navigating the Imperative of Immediate Change

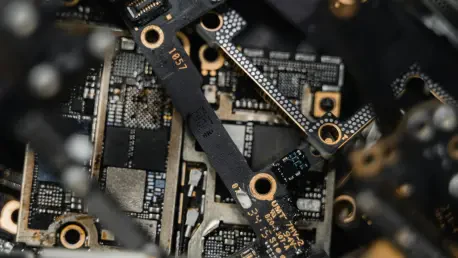

The call for digital transformation in manufacturing resonates louder than ever, driven by an unrelenting need to remain competitive in a technology-saturated environment. For many SMEs, the failure to modernize has already proven costly, with some losing vital contracts to rivals who have integrated advanced systems like robotics and artificial intelligence into their operations. The pressure to digitize stems from market demands that prioritize rapid delivery, tailored products, and environmentally conscious practices—standards unattainable without modern tools. This urgency is not a distant concern but a present-day reality, compelling manufacturers to act decisively to avoid being sidelined in a landscape where technological lag equates to business failure. The evidence is clear: digital adoption is the linchpin for meeting today’s benchmarks and securing long-term viability.

Compounding this urgency is the accelerating pace of industrial revolutions, which have compressed innovation timelines to just a few years. From the mechanized foundations of early industry to the smart factories of today, and now the dawn of even more advanced paradigms, the window to adopt transformative technologies like autonomous AI agents and digital twins is shrinking rapidly. For manufacturers, particularly SMEs with limited resources, hesitation can result in a competitive disadvantage that is nearly impossible to overcome. Technologies once considered futuristic are now becoming baseline expectations, reshaping how production lines operate and how customer needs are met. Embracing these advancements without delay is essential to keep pace with an industry that reinvents itself faster than ever before, ensuring relevance in a market that waits for no one.

Overcoming Barriers to Digital Adoption

Despite the undeniable need for digital transformation, SMEs in manufacturing face a host of formidable challenges that complicate their journey toward modernization. A significant obstacle is the pervasive skill gap among workforces, where a large proportion of employees lack the digital fluency required for emerging roles in AI and automation. This deficiency hampers the ability to implement and manage sophisticated systems, leaving many companies struggling to even begin the transition. Reports indicate that a substantial number of industrial positions now demand technological proficiency, a requirement that many current workers are unprepared to meet. Addressing this gap through targeted training and education is crucial, as without a capable workforce, the adoption of digital tools remains an unattainable goal for numerous smaller manufacturers.

Beyond skills, financial constraints pose another critical barrier, as most SMEs allocate only a fraction of their revenue to technological investments due to tight budgets and competing priorities. This investment gap is often worsened by a lack of awareness about accessible and appropriate digital solutions tailored to their scale. Additionally, the absence of dedicated leadership—such as Chief Digital Officers or tech-focused executives—creates a strategic void, leaving many firms without the vision or expertise needed to drive transformation. These structural challenges, combined with limited access to cutting-edge automation tools, make the path to digitization appear daunting. Yet, recognizing and tackling these hurdles head-on through partnerships and incremental steps can pave the way for meaningful progress in an economy where SMEs play a vital role.

Seizing Opportunities Through Technological Innovation

Amid the challenges, a wealth of opportunities awaits manufacturers willing to embrace digital transformation, particularly within the rapidly expanding automation market projected to see exponential growth over the coming years. SMEs stand to benefit immensely by collaborating with automation solution providers and digital enablers who offer tailored strategies for integrating robotics, Internet of Things (IoT) platforms, and AI systems. These partnerships can help address pressing issues like rising costs and stringent compliance requirements, enabling smaller firms to compete on a larger stage. By focusing on customized roadmaps and effective change management, manufacturers can transition to digital processes in a way that aligns with their unique needs and resources, transforming potential obstacles into stepping stones for growth and efficiency.

Technological innovations such as Generative AI and digital twins are already revolutionizing the manufacturing landscape, offering practical solutions that enhance operational performance across various domains. Generative AI, for instance, goes beyond traditional automation by managing dynamic, unstructured tasks, improving areas like procurement and predictive maintenance with remarkable precision. Digital twins, on the other hand, allow for real-time simulation of production outcomes, enabling companies to optimize processes before physical implementation. These tools are no longer optional extras but essential components of a competitive strategy, as they directly respond to market expectations for efficiency and sustainability. Manufacturers adopting such technologies must also prioritize workforce retraining to ensure employees can effectively collaborate with these systems, securing a future where innovation drives success.

Building a Future with Human-AI Collaboration

The evolution of technology in manufacturing is reshaping the workforce, replacing traditional roles with hybrid positions that leverage AI to boost productivity and innovation. Tasks that once required large teams can now often be handled by smaller, tech-savvy units supported by intelligent systems, streamlining operations significantly. While concerns about AI displacing human jobs persist, it’s evident that human creativity, ethical judgment, and emotional intelligence remain irreplaceable, ensuring a complementary rather than competitive dynamic. The focus should be on upskilling employees to work alongside AI, fostering an environment where technology amplifies human potential rather than diminishes it. This collaborative approach is vital for maintaining a balance that benefits both efficiency and the human element in manufacturing.

To achieve this synergy, manufacturers must invest in comprehensive training programs that equip workers with digital literacy as a fundamental skill, akin to basic computer proficiency in previous decades. Real-world examples highlight the impact of such initiatives, with companies reducing operational downtime and improving supply chain reliability through AI-driven tools after retraining their staff. Starting with small-scale projects, such as automating compliance processes or implementing digital twins for a single production line, allows firms to build confidence and expertise before scaling up. This gradual integration ensures that the workforce adapts alongside technological advancements, creating a sustainable model where human insight and AI precision work hand in hand to drive manufacturing forward into a digitally empowered future.

Reflecting on Transformative Steps Taken

Looking back, the journey of digital transformation in manufacturing revealed a landscape where immediate action proved decisive for survival and growth. SMEs that took bold steps to integrate technologies like AI, IoT, and digital twins often found themselves ahead of the curve, with reduced downtime and enhanced compliance efficiencies as tangible outcomes of their efforts. The past showed that hesitation carried heavy costs, as those slow to adapt struggled to meet market demands for speed and customization. Partnerships with digital enablers and a commitment to incremental implementation emerged as critical strategies that turned challenges into opportunities for many.

Moving forward, the focus should shift to actionable next steps that build on these early successes, ensuring sustained progress in a competitive arena. Manufacturers are encouraged to prioritize scalable pilot projects, focusing on specific pain points like predictive maintenance or supply chain optimization, before expanding across operations. Governments and industry bodies can play a pivotal role by offering incentives and accessible training programs to bridge skill gaps, particularly for SMEs with limited resources. By fostering an ecosystem that supports continuous learning and innovation, the manufacturing sector can solidify its foundation for a future where digital tools and human ingenuity combine to redefine industry standards, setting a precedent for resilience and adaptability.