In the rapidly evolving landscape of technology and engineering, the need for innovation has never been more crucial. A notable point of progress is occurring at Kennesaw State University, where an initiative led by undergraduate student Carter Corbin is redefining the future of smart manufacturing. Specializing in mechatronics engineering, Corbin, alongside a team of students and researchers, is integrating cutting-edge robotics and digital twin technology to revolutionize automation in manufacturing, setting a new standard for efficiency and adaptability in the ever-dynamic tech industry.

The Essence of Digital Twin Technology

Real-Time Interaction and Communication

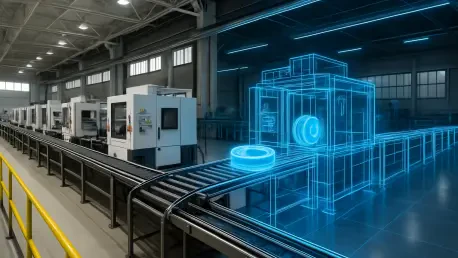

Digital twin technology, as spearheaded by Corbin and his colleagues, offers a groundbreaking approach to manufacturing by providing a virtual replica of physical machines. These digital counterparts are continuously updated to mirror real-world changes in real-time, creating a dynamic communication channel between digital and physical entities. This interactive quality sets it apart from traditional simulation models. Engineers and developers can proactively evaluate processes and detect potential issues without physically interrupting production, mitigating risks associated with real-world testing. By swiftly addressing these errors, manufacturing entities can avert costly disruptions, enhancing overall operational efficiency.

The implementation of digital twins in manufacturing processes presents numerous benefits beyond risk avoidance. This innovative system facilitates continuous monitoring and improvement, adapting in real-time to changing conditions or demands. Within Corbin’s project, this capability is illustrated through a small-scale simulation featuring a conveyor system with a robotic arm and puck. The system provides live data feedback, empowering manufacturers to make informed decisions swiftly and refine problem-solving strategies. By aligning decision-making with real-time insights, manufacturing operations can become more intelligent, flexible, and responsive to new challenges.

Transformative Potential in Manufacturing

The work conducted by Corbin’s team, characterized by a unique blend of interdisciplinary expertise and collaborative spirit, extends beyond theoretical exploration, signifying a tangible shift in how industries can leverage digital twin technology. The research findings captured notable attention, culminating in a presentation at the ASME IMECE 2025 conference, where it showcased the profound implications of digital twins in modern manufacturing. As emphasized by Gershom Richards, a Ph.D. candidate and key member of the research team, digital twins are poised to become invaluable tools for enhancing data accuracy and refining operational decisions.

Corbin and his team’s commitment to advancing digital twin technology signals an evolution within the manufacturing landscape. By integrating complex and precise simulations, industries can achieve an unprecedented level of operational efficiency, driven by data-centric insights. This advancement enables manufacturing systems to be operated with enhanced precision, anticipating potential failures and optimizing resource allocation. The comprehensive simulations possible with digital twins facilitate sophisticated visualizations, accommodating intricate elements like multiphysics, which intertwine various scientific principles, thus providing a holistic view of manufacturing processes.

Scholarly Journey and Academic Excellence

Embracing Mechatronics at Kennesaw State

Carter Corbin’s foray into the field of mechatronics engineering underscores a journey of academic discovery and change. Hailing from McDonough, Georgia, Corbin transitioned from Gordon State College to Kennesaw State University after learning about its distinctive mechatronics program. This interdisciplinary field melds mechanical, electrical, and computer engineering principles, offering a dynamic learning path that resonates with Corbin’s desire for a multifaceted engineering education. His academic endeavors exemplify how students navigate evolving educational pathways, exploring emergent fields that blend traditional disciplines with future-focused technologies.

Corbin’s exposure to practical research began with an automation project in a fluid power course taught by associate professor David Guerra-Zubiaga. This experience catalyzed Corbin’s interest in real-world research applications. Recognizing Corbin’s academic potential and aptitude for collaborative work, Guerra-Zubiaga provided guidance and opportunities to link hands-on learning with theoretical knowledge. As a leader within his research team, Corbin exemplified a promising scholar in engineering, seamlessly integrating his learning experiences into noteworthy research contributions.

Overcoming Challenges and Moving Forward

In the realm of automation and digital twin research, Corbin and his team encountered significant challenges, particularly in integrating various hardware components with Siemens PLCs vital to industrial automation systems. Navigating compatibility issues required constant troubleshooting, providing key experiential learning opportunities for Corbin and his team members. Moving through these challenges highlighted the importance of hands-on trials for developing and deploying integrated automation systems in manufacturing effectively. The solutions they devised contributed pivotal insights into how modern automation systems could converge with cutting-edge digital twin capabilities.

Upon completion of his undergraduate program in Spring 2025, Corbin plans to pursue a Master of Science in Intelligent Robotic Systems at Kennesaw State University. His aspirations align with a desire to explore the Robot Operating System (ROS) 2 for robotic simulation and communication further, paving the way for a future Ph.D. in robotics. Engaging with assistant professor Muhammad Tanveer, Corbin aims to deepen his expertise in real-time robotic system communication, ensuring his skill set aligns with the demands of future advancements in robotics and automation.

Preparing for a Digital Manufacturing Future

A Foundation in Real-World Applications

The research laboratory at Kennesaw State University, where Corbin and his team operate, continues to emphasize real-world constraints and practical preparation. The absence of industry partnerships has not limited their progress; instead, standard systems supported by Siemens provide a framework for implementing the theoretical aspects of their research into practice. This pragmatic approach ensures that students and researchers accumulate essential skills and experience while creating systems where digital twins seamlessly coexist with physical machinery. The team’s efforts encapsulate a fundamental shift in smart manufacturing, reflecting broader trends in the technological landscape.

The interactivity and precision offered by digital twins highlight their potential to redefine traditional manufacturing methods, enhancing flexibility and adaptability. As Corbin and his colleagues demonstrate, these technologies do more than streamline processes; they enable active learning environments that bridge academic inquiry and practical application. Through their work, Kennesaw State University establishes itself as a pivotal institution in fostering technological advancement by nurturing innovative talent capable of addressing the multifaceted challenges in contemporary manufacturing.

Institutional Support and Collaborative Growth

In today’s swiftly changing realm of technology and engineering, innovation stands as a pivotal necessity. Amidst this transformation, a significant advancement is unfolding at Kennesaw State University. Here, undergraduate student Carter Corbin is spearheading an ambitious initiative that’s set to transform smart manufacturing. Corbin, who majors in mechatronics engineering, collaborates with a group of dedicated students and researchers, working tirelessly to merge sophisticated robotics with digital twin technology. This pioneering effort aims to overhaul automation within manufacturing processes, thus establishing a novel benchmark for efficiency and adaptability in the technology sector, which is perpetually in flux. This undertaking not only demonstrates the potential of integrating technology and education but also highlights the pivotal role that young innovators play in shaping the future. Their work not only serves to redefine current protocols but also paves the way for future technological advancements that could have wide-reaching impacts across various industries.