What happens when a critical piece of military equipment fails in the middle of a remote battlefield, with no spare parts in sight and supply lines stretched thin? This scenario, all too common in modern defense operations, underscores a pressing need for rapid, reliable solutions to keep missions on track. Enter the Digital Supply Chain for on-Site Maintenance in Defense by Additive Manufacturing (DISCMAM), a groundbreaking project leveraging 3D printing technology to revolutionize how military forces address maintenance challenges in high-stakes environments. This initiative promises to transform logistics by enabling on-site repairs and manufacturing, ensuring operational readiness even under the toughest conditions.

The significance of DISCMAM lies in its potential to redefine defense maintenance at a time when speed and adaptability are paramount. Traditional supply chains often falter with long delays and logistical barriers, especially in isolated or hostile zones. By integrating additive manufacturing (AM), this project offers a way to produce or repair critical components directly where they are needed, slashing downtime and enhancing mission success. With global defense budgets facing scrutiny and the push for digital transformation intensifying, DISCMAM emerges as a timely innovation that could set new standards for military efficiency and resilience.

Revolutionizing Defense Maintenance: Why DISCMAM Matters Now

In an era where military operations demand agility, the ability to maintain equipment without waiting for distant shipments is a game-changer. DISCMAM focuses on creating secure, deployable systems that allow soldiers to print or repair parts on-site using advanced 3D printing techniques. This approach not only addresses immediate operational needs but also reduces dependency on complex supply networks, which can be vulnerable to disruption during conflicts.

The project, now in its decisive phase toward completion by November 2026, aligns with broader trends in defense toward self-sufficiency and technological integration. By tackling real-time maintenance challenges, DISCMAM ensures that forces remain combat-ready, minimizing risks associated with equipment failure. Its emphasis on digital solutions also positions it as a cornerstone for future military logistics, where innovation must keep pace with evolving threats.

The Stakes of On-Site Defense Manufacturing

Downtime in warfare isn’t just an inconvenience—it can be a fatal liability. When equipment breaks down in remote areas, traditional repair methods often involve weeks of waiting for parts to arrive through cumbersome supply chains. DISCMAM counters this vulnerability by developing AM technologies that enable immediate production and repair, directly at the point of need, ensuring that critical systems are back online swiftly.

Beyond speed, the initiative addresses security concerns inherent in modern defense operations. By localizing manufacturing, it reduces the risk of interception or tampering during transport. This localized approach, paired with stringent quality controls, meets the high standards required for military applications, offering a robust alternative to conventional methods while maintaining operational integrity in sensitive environments.

Key Technical Milestones Driving DISCMAM Forward

Over the past six months, DISCMAM has achieved impressive technical progress, showcasing its potential to transform defense maintenance. A cybersecure digital pathway, spearheaded by Accenture, ensures safe data sharing and remote support, adhering to strict EU military standards while protecting connections with AM machines. This framework is vital for maintaining confidentiality in high-stakes scenarios.

Additionally, project coordinator LORTEK has refined on-site workflows and monitoring systems to cut downtime significantly, ensuring high-quality repairs and production of new components. Meanwhile, the Danish Technological Institute (DTI) has advanced Powder Bed Fusion-Laser Beam (PBF-LB) techniques, improving manufacturing quality and enabling digital qualification of parts without extra testing. Finally, ADAXIS has virtualized the Directed Energy Deposition-Laser Beam (DED-LB) process for precise repairs, enhancing efficiency in path planning. These milestones reflect a cohesive effort to merge digital security with physical accuracy.

Insights from the Consortium: Collaboration and Confidence

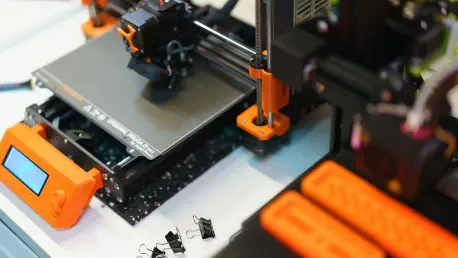

At a recent Consortium Meeting in Aarhus, Denmark, hosted by DTI, project partners expressed unwavering confidence in DISCMAM’s direction. A senior representative from LORTEK remarked, “The benchmarks we’re setting for on-site manufacturing are unprecedented in defense applications.” This optimism was palpable during a tour of DTI’s Centre for Industrial 3D Printing, where cutting-edge facilities demonstrated the tangible impact of the project’s innovations.

With nearly six work packages completed and focus now shifting to the next reporting period starting this year, the collaboration among partners like Accenture, LORTEK, DTI, and ADAXIS remains a driving force. Their combined expertise ensures that technical advancements are not just theoretical but primed for real-world deployment, reinforcing trust in the project’s trajectory as it moves into critical integration phases.

Practical Steps for Shaping the Future of Defense AM

As DISCMAM approaches its final year, defense organizations and industry stakeholders can draw actionable lessons from its progress. Prioritizing cybersecurity through frameworks like the digital pathway ensures safe data handling in sensitive operations. Investing in process monitoring tools, as exemplified by LORTEK’s strategies, can maintain quality and reduce operational delays, a critical factor in mission success.

Exploring virtualized repair processes, such as ADAXIS’s DED-LB innovations, offers precision for complex maintenance tasks. Additionally, engaging with DISCMAM’s upcoming showcases at events like Formnext and the AM Village event hosted by the European Defence Agency provides opportunities to witness deployable systems in action, with live demonstrations by core partner Fieldmade. These steps form a practical blueprint for integrating AM into defense logistics, balancing innovation with security and efficiency.

Looking back, the journey of DISCMAM highlighted a remarkable convergence of technology and necessity during its pivotal Consortium Meeting in Aarhus. The technical strides and collaborative spirit demonstrated there laid a solid foundation for what’s next. Moving forward, defense sectors worldwide should consider adopting these on-site manufacturing solutions, staying tuned to upcoming demonstrations for insights on implementation. As the project nears its 2026 conclusion, its legacy could inspire a broader shift toward agile, secure maintenance systems, ensuring military forces are better equipped for tomorrow’s challenges.