At EMO Hannover, Fehlmann Maschinenfabrik is captivating the attention of the global manufacturing community with its state-of-the-art machine tools and automation solutions. Among the highlights is the emphasis on precision and versatility, essential for evolving manufacturing demands. Fehlmann’s showcase is a testament to their commitment to smart machining, underlining the innovation required for small-batch and single-part production sectors. This impressive display is centered around several advanced machining solutions that underscore the brand’s forward-thinking approach in precision engineering and automation.

Advanced Automation in Manufacturing

Picomax 550 PRO: A Compact Powerhouse

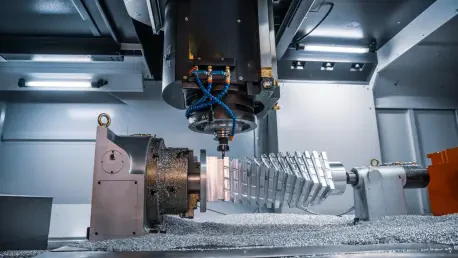

The spotlight at Fehlmann’s exhibit shines brightly on the new Picomax 550 PRO CNC machine, an emblem of adaptability and precision in modern manufacturing. This compact yet universal 5-axis machine perfectly addresses the dynamic needs of current production environments. A standout feature is its seamless integration with a 6-axis robotic system, automating the critical processes of loading and unloading workpiece pallets. This synergy not only boosts productivity but also enhances operational efficiency by minimizing manual intervention. Centralized control through the Fehlmann Milling Center Manager (MCM™) ensures maximum transparency, making quick adjustments easy and facilitating seamless workflow integration.

This integration speaks volumes about how Fehlmann is addressing the industry’s pressing demand for smart manufacturing environments, especially for sectors that necessitate flexible batch production. The Picomax 550 PRO is not just another machine tool; it represents a new paradigm in machining flexibility and efficiency. This machine is instrumental in redefining production norms, indicating a move towards more efficient and streamlined manufacturing practices that can handle a broad range of production challenges with ease and precision.

Versa 745 and 645: Pioneering Multi-Functionality

Fehlmann also impresses with the Versa 745, the product of innovation combined with the Erowa Robot Compact 150. This integration facilitates the automated handling of workpieces weighing up to 150 kilograms. The Versa 745 exemplifies Fehlmann’s commitment to space-efficient, high-performance solutions that cater to the varied demands of modern-day manufacturing. Additionally, the Versa 645 linear model is a standout for merging 5-axis milling with grinding capabilities within one system. This reduction in lead times and improvement in component quality is achieved by facilitating complete machining in a single setup, which underscores the machine’s functional versatility.

Fehlmann’s approach to integrating multiple functionalities into single systems stands as a testament to their commitment to innovation. These advanced solutions not only streamline manufacturing processes but also set new benchmarks in terms of efficiency and part quality. Such innovations demonstrate Fehlmann’s dedication to leveraging technology to continually enhance machining productivity, offering scalable solutions tailored to meet specific industry needs in a compact form factor.

Focus on Education and Usability

Training-Centric Models: Picomax and Versatility

In addition to advanced automation technologies, Fehlmann presented the Picomax 56 L TOP and Picomax 56 mill as practical solutions emphasizing educational usability. These versatile models adeptly manage dual operations, offering manual and CNC functions ideal for vocational training settings and low-volume production runs. The educational aspect is critical, as Fehlmann empowers the next generation of machinists with hands-on training that bridges the gap between theoretical knowledge and practical application.

The educational perspective is further reinforced through the Picomax 21-M, primarily designed for low-volume production and training purposes. Its design emphasizes simplicity and user-friendliness, essential in training environments where ease of use is crucial. Manual and automated options enhance its adaptability, catering to diverse learning and operational scenarios. This focus supports the continuous development of skills critical for maintaining competitiveness in today’s fast-paced manufacturing landscape, affirming Fehlmann’s commitment to skill development.

Technological Integration for Enhanced Productivity

Equipping these training-centric machines with the Heidenhain TNC7 control system showcases a trend toward intuitive interfaces designed to enhance user-friendliness and productivity. Heidenhain’s role as a training partner ensures that users gain invaluable hands-on experience, promoting effective onboarding and operational efficiency. Such collaborations highlight the strategic importance of blending advanced technology with user-centric interfaces, ensuring that operators can transition smoothly from training to real-world manufacturing scenarios.

Harnessing these innovative control systems demonstrates Fehlmann’s strategic intent to bridge technological advancements with practical educational tools. This approach not only prepares learning environments for future challenges but also ensures that the transition into professional settings is fluid, fostering a forward-thinking culture within the industry. Through such initiatives, Fehlmann positions itself as a leader in integrating education with cutting-edge technology, thus underscoring its holistic approach to modern manufacturing.

Strategic Insights for Evolving Manufacturing Needs

At the prestigious EMO Hannover trade fair, Fehlmann Maschinenfabrik is grabbing the attention of industry leaders and professionals worldwide with its cutting-edge machine tools and innovative automation solutions. A major highlight of Fehlmann’s presentation is the focus on precision and versatility, both of which are crucial to meeting the ever-changing demands in the manufacturing industry. Their exhibition is a clear reflection of their dedication to smart machining and the innovation that is essential for the niche of small-batch and single-part production sectors. This standout showcase revolves around several advanced machining solutions that not only highlight Fehlmann’s expertise but also demonstrate their forward-thinking and innovative approach in precision engineering and automation. By emphasizing these qualities, Fehlmann effectively communicates their strategic vision for adapting to and leading in today’s technologically-driven manufacturing landscape, ensuring they meet the specific needs of their clients and partners across the globe.