Formic, a pioneering provider of Robots-as-a-Service (RaaS) automation solutions for U.S. manufacturers, has recently raised an impressive $27.4 million in Series A financing. The funding round, led by Blackhorn Ventures and supported by several notable investors, underscores a growing industry acknowledgment of the importance of accessible automation technology. This article explores how Formic is leveraging this capital to tackle the challenges U.S. manufacturers face and the implications for the future of automation in the industry.

Formic’s Vision and Objectives

Bridging the Gap in Automation Adoption

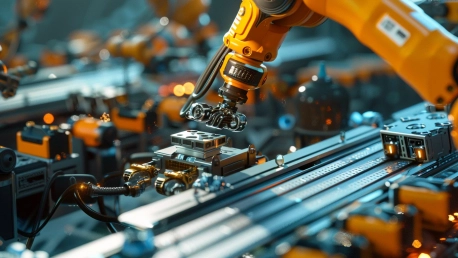

Automation has long been seen as a complex and capital-intensive leap for many manufacturers, especially small- and mid-sized enterprises. Formic’s innovative RaaS model bridges this gap by providing comprehensive solutions that include continuous monitoring, maintenance, and deployment of robotic systems at an affordable hourly rate. This model is designed to eliminate the technical and financial barriers that have historically prevented widespread adoption of advanced robotics, allowing businesses to focus on their core operations without worrying about the complexities of automation. By offering a pay-as-you-go model, Formic ensures that manufacturers can access cutting-edge technology without substantial upfront investment. The continuous support and maintenance provided by Formic further simplify the adoption process, as manufacturers do not need to hire specialized staff to manage these systems. This democratization of automation technology aligns perfectly with the modern needs of the manufacturing sector, particularly as companies seek to remain competitive in an increasingly automated global market.

Addressing U.S. Manufacturing Challenges

The U.S. manufacturing sector faces significant hurdles, including labor shortages and high capital expenditure requirements for implementing automation. Formic is positioned to alleviate these burdens through its flexible financing options and rapid deployment capabilities. Saman Farid, co-founder and CEO of Formic, emphasizes that their approach simplifies robotic system financing, deployment, management, and support, enabling manufacturers to enhance productivity without needing specialist expertise. This is particularly essential as the sector contends with an aging workforce and a shortage of skilled labor. With Formic’s RaaS model, manufacturers can mitigate the risks associated with large-scale capital investments in automation equipment. Instead of bearing the full cost of purchasing and maintaining robotic systems, businesses can deploy these systems on a more manageable budget. Rapid deployment capabilities ensure that manufacturers see a quick return on investment, as the robotic systems can be integrated swiftly without lengthy lead times. This approach is especially beneficial for manufacturers looking to scale their operations efficiently without sacrificing quality or safety.

Achievements and Growth Metrics

Expansion and Performance Metrics

Since its inception in 2020, Formic has shown remarkable progress, with its fleet of robotic equipment achieving over 100,000 production hours at an uptime rate exceeding 99%. The company anticipates another 100,000 hours within the next 170 days, signaling rapid scaling of their operations. This growth validates the efficacy of Formic’s model and its potential to revolutionize the manufacturing landscape. The consistent uptime rate speaks volumes about the reliability and effectiveness of Formic’s robotic systems, instilling confidence in both current and potential customers. The ability to maintain such high uptime rates is crucial for manufacturers who rely on continuous production. Any downtime can significantly impact productivity and profitability. Formic’s commitment to maintaining these high standards demonstrates its dedication to customer satisfaction and operational excellence. As the company continues to expand its fleet and improve its service offerings, the future looks promising for manufacturers looking to integrate advanced automation into their processes.

Customer Satisfaction and Retention

Formic’s high rate of customer satisfaction is evidenced by an impressive 97% renewal rate among clients whose contracts have expired. The company has doubled its customer base, deployed three times more systems, and seen a sevenfold increase in total robot production hours. This level of repeat business and contract renewals highlights the effectiveness and appeal of Formic’s solutions. Such metrics not only showcase the reliability of their robotic systems but also the trust and confidence that customers place in Formic’s services. Customer retention is a key indicator of a company’s success and the value it provides to its clients. Formic’s ability to double its customer base while maintaining high renewal rates speaks volumes about its market penetration and customer loyalty. These achievements reflect the company’s unwavering commitment to delivering top-notch services and support. As Formic continues to enhance its offerings and expand its reach, it sets a high standard for innovation and customer satisfaction in the automation industry.

Strategic Investment and Industry Collaboration

Partnering with Industry Leaders

The Series A financing round brought in investments from major players like Mitsubishi HC Capital America and NEC. These partnerships are crucial for Formic’s growth strategy, allowing for innovations in robotic automation software and infrastructure. The joint commercial agreement with Mitsubishi HC Capital will enable Formic to source and finance the entire lifecycle of its RaaS model, enhancing its service offerings. This collaboration underscores the importance of strategic alliances in driving technological advancements and achieving business objectives. Such partnerships bring together complementary expertise and resources, facilitating more comprehensive and innovative solutions. By joining forces with industry leaders, Formic can accelerate its R&D efforts and bring more advanced robotic technologies to market faster. These collaborations are essential for staying ahead in the rapidly evolving automation landscape, ensuring that Formic remains at the forefront of innovation and continues to provide unparalleled value to its customers.

Enabling Advanced Robotic Solutions

Investment from contributors like Lux Capital and Initialized Capital will support the development of Formic’s equipment-agnostic robotic automation software. This software incorporates artificial intelligence for advanced motion planning, predictive maintenance, and system design. Enhanced customer interfaces and dashboards will further simplify interactions for manufacturers, contributing to easier and more effective automation deployment. Such advancements position Formic’s solutions as not only functional but user-friendly, broadening their appeal across various manufacturing sectors. AI-driven features in robotic systems enhance their capabilities and performance, making them more versatile and efficient. Predictive maintenance, for instance, allows for timely interventions, reducing unexpected downtimes and prolonging the lifespan of the equipment. Enhanced customer interfaces make it easier for manufacturers to interact with robotic systems, streamline operations, and monitor performance metrics. These improvements reflect Formic’s commitment to continuous innovation and customer-centric solutions.

Industry Impact and Future Outlook

Importance of Democratizing Automation

The current utilization rate of automation in U.S. manufacturing is a mere 10%, as reported by MIT. Formic’s approach to democratizing automation, particularly for small- and mid-sized enterprises, is crucial in addressing labor shortages and driving growth. Melissa Cheong of Blackhorn Ventures echoes this sentiment, highlighting the importance of unlocking manufacturing capacity and creating a resilient supply chain. By making automation accessible, Formic paves the way for a more competitive and efficient manufacturing sector that can adapt to changing market demands. The democratization of automation is essential for creating a level playing field where even smaller manufacturers can benefit from advanced technologies. This approach helps mitigate the impact of labor shortages by enabling businesses to maintain high productivity levels with fewer human resources. Moreover, automating repetitive and hazardous tasks improves workplace safety and allows workers to focus on more value-added activities. As more manufacturers adopt these technologies, the cumulative effect will be a more robust and agile manufacturing ecosystem.

Addressing Future Workforce Needs

Projections indicate that the U.S. manufacturing sector will require up to 3.8 million new employees by 2033, with 1.9 million jobs potentially going unfilled. Automation is seen as a viable solution to bridge this gap. Formic’s commitment to making advanced robotics accessible supports this vision, ensuring manufacturers can continue to thrive amidst growing demands and labor shortages. By alleviating the pressure on human resources, automation enables manufacturers to scale operations and meet production targets more efficiently. The integration of robotic systems into manufacturing processes not only fills labor gaps but also enhances overall productivity and quality. Automated systems can work around the clock, maintaining consistent output levels and reducing the likelihood of errors. This reliability is particularly crucial in industries with stringent quality standards and tight production schedules. Formic’s focus on accessibility ensures that even manufacturers without extensive technical expertise can harness the benefits of automation, thereby securing their competitive edge in the market.

Enhancing U.S. Support Network

Improving Service Levels

With new funding, Formic plans to expand its U.S. support network, ensuring faster customer response times and maintaining high standards for service level agreements (SLAs). This network expansion is pivotal for providing reliable and timely support to manufacturers, which is essential for maintaining high uptime rates and customer satisfaction. Rapid and effective support services minimize disruptions and ensure that the robotic systems operate smoothly, further bolstering the confidence of manufacturers in adopting Formic’s solutions. An expanded support network also allows for more personalized and localized service, addressing specific needs and concerns of individual clients. As Formic continues to grow, enhancing the support infrastructure ensures that all customers, regardless of their location, receive consistent and high-quality service. This focus on customer support is a vital component of Formic’s strategy, reinforcing its commitment to delivering comprehensive and dependable automation solutions.

Accelerating Lead Times

The capital raised will also help in reducing lead times for robotic system deployment. Formic has already achieved a fourfold reduction in deployment time from the point of a signed contract. Further improvements will enable manufacturers to swiftly implement automation solutions, thereby accelerating their production capabilities. Shorter lead times translate to quicker returns on investment and faster scaling of operations, making Formic’s solutions even more attractive to manufacturers. Reducing lead times is particularly important in industries where time-to-market is a critical factor. The ability to deploy robotic systems swiftly allows manufacturers to respond promptly to market demands and production challenges. This agility is a competitive advantage in a fast-paced and dynamic industry landscape. Formic’s ongoing efforts to streamline the deployment process reflect its proactive approach to meeting customer needs and enhancing the overall efficiency of manufacturing operations.

Conclusion

Formic, a trailblazer in providing Robots-as-a-Service (RaaS) for U.S. manufacturers, recently secured $27.4 million in Series A funding. This significant investment round, led by Blackhorn Ventures and bolstered by various renowned backers, highlights a growing recognition in the industry of the critical role of accessible automation technology. Formic aims to use this financial boost to address the pressing challenges U.S. manufacturers face, such as labor shortages and the need for enhanced productivity. By offering innovative automation solutions, Formic enables manufacturers to adopt advanced technologies without the burden of significant upfront investments. This approach is poised to democratize access to automation, making it feasible even for smaller manufacturing entities to compete on a global scale. The infusion of capital not only strengthens Formic’s market position but also signals a broader trend toward the adoption of RaaS models in the manufacturing sector. As Formic continues to innovate and expand, the future of automation in U.S. manufacturing looks promising and increasingly automated.