The rapid expansion of power-hungry sectors like artificial intelligence, data centers, and renewable energy has exposed a critical vulnerability in the national infrastructure: a severe and prolonged shortage of medium-voltage transformers. This single component has become a primary bottleneck, stalling new projects and threatening to derail the nation’s technological and clean energy ambitions by creating multi-year backlogs for essential power grid components. In response to this pressing challenge, Giga Energy, a U.S.-based manufacturer of power infrastructure, has announced a significant strategic initiative aimed directly at alleviating this supply chain crisis. The company is establishing a new, state-of-the-art production facility in Houston, Texas, a move designed to reshore critical manufacturing capabilities and provide a reliable domestic source for the hardware needed to power the next wave of innovation. This development marks a pivotal effort to address the infrastructure gap from within, leveraging American manufacturing to support urgent national needs.

A Strategic Move to Bolster Domestic Production

Giga Energy’s new 60,000-square-foot factory represents a substantial investment in domestic manufacturing capacity, strategically located in Houston to capitalize on the region’s robust industrial ecosystem. The facility is slated to begin production in the first quarter of 2026, with an ambitious plan to rapidly scale its operations. At full capacity, the plant is projected to manufacture over 3,000 MV transformers annually, translating to an impressive 15 gigawatts of power capacity per year. This output is poised to make a significant dent in the current supply chain delays that have plagued developers and utility companies. Beyond its impact on the power grid, the factory is set to become a notable source of local economic growth. The initiative will initially create 25 new jobs, with that number expected to grow to nearly 100 skilled manufacturing roles as production ramps up. This expansion not only addresses a critical national shortage but also reinforces the company’s commitment to fostering local employment and strengthening the American manufacturing base for essential infrastructure components.

Integrating Advanced Technology and Supply Chain Control

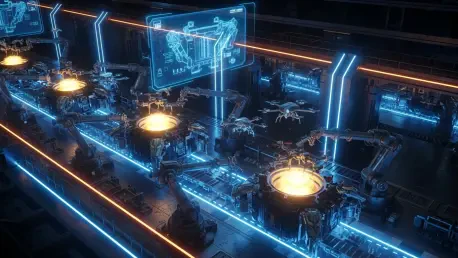

A cornerstone of the Houston facility’s strategy is the integration of cutting-edge manufacturing technology to optimize both efficiency and product quality. A standout feature will be the use of an innovative terahertz drying oven, a technology designed to dramatically accelerate the moisture removal process during transformer production. This advanced method ensures greater consistency in product quality while significantly reducing manufacturing cycle times, allowing Giga Energy to respond more quickly to market demands. By establishing a vertically integrated production base in the United States, the company also gains end-to-end control over its supply chain. This control is crucial for mitigating the risks associated with international logistics and ensuring more reliable delivery schedules for its customers. CEO Matt Lohstroh emphasized that this facility embodies the company’s core mission: combining sophisticated technology with the strength of American production. This approach not only provides a solution to the nation’s urgent infrastructure needs but also guarantees a higher standard of quality and reliability for the critical components that underpin the modern economy.

Forging a Path for Infrastructure Resilience

The announcement of the Houston factory marked a decisive step toward resolving a deep-seated vulnerability in the American power infrastructure. Giga Energy’s commitment to domestic production represented more than just a corporate expansion; it was a strategic response that directly confronted the supply chain frailties that had hampered progress across key industries. This initiative set a powerful precedent for how private enterprise could address national-level challenges by investing in local manufacturing and advanced technology. The plan was widely seen as a tangible solution that promised to shorten lead times, enhance grid stability, and support the continued growth of sectors vital to the nation’s economic future. By localizing the production of such a critical component, the company not only aimed to meet immediate demand but also laid the groundwork for a more resilient and self-sufficient energy infrastructure for years to come.