The manufacturing industry currently stands at a pivotal moment, with Artificial Intelligence promising to usher in a new era of unprecedented efficiency and groundbreaking innovation. The critical question facing leaders, however, is not if AI will change the sector, but how this transformation can be genuinely and effectively realized across the entire value chain. A clear consensus is emerging from industry pioneers that the true, sustainable power of AI is unleashed only when it moves beyond theoretical demonstrations and becomes a deeply embedded, operational tool on the factory floor. This fundamental shift in perspective—from AI as a conceptual novelty to a core industrial process—is the essential key to unlocking its potential to fundamentally reshape production, quality control, and overall operational intelligence for the modern enterprise.

The Core Principles of Practical AI Integration

Moving Beyond the “Demo” Phase

A powerful and recurring theme among industry experts is the assertion that any AI that does not directly enter and influence the production process is essentially just a sophisticated demonstration. For Artificial Intelligence to deliver a tangible and measurable return on investment, it must be meticulously applied to solve the concrete, real-world problems that define the manufacturing workflow. Its ultimate value is found not in its technological novelty but in its proven ability to augment and automate critical, often complex, tasks in areas such as order processing, dynamic production scheduling, predictive quality control, and continuous process optimization. This practical application directly impacts the bottom line, drives efficiency gains, and enhances competitive advantage. The focus, therefore, must remain on leveraging AI to solve specific, pressing issues within the production environment, ensuring that the technology serves a clear and strategic purpose rather than being adopted for its own sake. This problem-driven mindset is the foundational first step toward a successful and transformative AI integration.

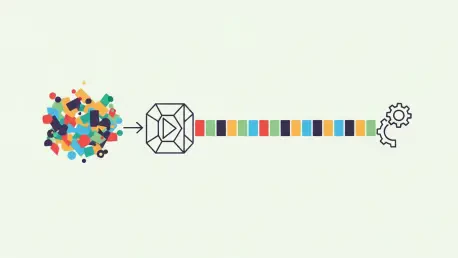

The conversation around industrial AI has significantly evolved beyond the capabilities of singular large language models to embrace the far more potent concept of the “Composite Intelligent Agent.” These agents are not merely advanced chatbots; they are complex, integrated systems that synergistically combine large-scale industrial time-series models, sophisticated industrial vision models, and a suite of professional tool add-ons tailored to specific manufacturing tasks. This advanced architecture allows the AI to graduate from simply understanding human language to fluently interpreting “machine language”—the intricate and continuous data streams of current, voltage, vibration, and other sensor outputs from production equipment. By processing this raw machine data, these composite agents can uncover deep, actionable insights into the physical manufacturing processes that were previously invisible. This capability moves the technology from a passive analytical tool to an active participant in the workflow, capable of diagnosing anomalies, predicting failures, and optimizing operations in real time, thereby creating a truly intelligent and responsive production environment.

Building the Foundation: Platforms and People

Given the immense diversity and inherent complexity of challenges across the global manufacturing landscape, it is clear that no single entity or standalone product can provide a universal solution. The most effective and scalable approach emerging is a “Platform + Ecosystem” model, which fosters collaboration and specialization. In this paradigm, a central platform provides the foundational technological capabilities—robust computing power, seamless access to a variety of powerful AI models, and intuitive low-code development tools. This core infrastructure acts as an operating system for enterprise AI, empowering a vibrant ecosystem of partners who bring deep, industry-specific knowledge, specialized algorithms, and practical deployment experience. This collaborative model enables the agile and rapid development of highly specialized AI agents that can effectively tackle the differentiated, long-tail scenarios unique to individual manufacturers and their specific production lines, making advanced AI accessible and customizable for a wide range of industrial applications.

Ultimately, for any technological transformation to succeed, it must be centered on human empowerment, and AI is no exception; the most successful integrations position AI as a tool to augment human capabilities, not replace them. This human-centric approach is proving crucial for widespread and enthusiastic adoption within the manufacturing sector. Leading companies are actively implementing ambitious plans to equip their front-line workers with intuitive AI tools, thereby transforming them from physical executors of tasks into intelligent, data-driven problem-solvers. By democratizing access to AI-powered applications, such as low-code platforms that allow business departments to create their own solutions without extensive IT support, these organizations empower their teams to innovate from the ground up. This strategy fosters a powerful cultural shift where AI is viewed not as an external threat but as an accessible and collaborative tool that enhances decision-making, improves efficiency, and drives a culture of continuous improvement at every level of the organization.

Strategic Pathways to AI-Powered Manufacturing

Establishing the Right Framework

A successful and sustainable journey into AI-powered manufacturing begins with the establishment of the right philosophical and technical framework from the outset. The guiding philosophy must be fundamentally user-centric and problem-driven, ensuring that AI is adopted not as a technological mandate but as a strategic tool to solve specific, pressing business issues. This practical mindset must be supported by a flexible, powerful, and scalable technical infrastructure, often conceptualized as an “Agent OS.” This foundational layer is explicitly designed to meet the high-mix, low-volume, and extensive customization needs that characterize modern manufacturing. It enables both the agile development of new AI applications in a “development state” and their efficient, reliable execution in an “operation state.” This dual-paradigm structure provides the necessary agility to innovate quickly while maintaining the stability required for critical production environments, creating a robust backbone for the enterprise’s entire AI strategy.

For an industry where production data is not just information but a highly sensitive and valuable corporate asset, the principles of data security and disciplined data engineering are non-negotiable pillars of any AI strategy. A trustworthy AI framework must be built upon a platform that guarantees uncompromising security through a multi-layered defense system, including features like fully-fledged private deployment options, stringent end-to-end data encryption, robust and granular permission systems, and comprehensive full-link auditing capabilities. This ensures a company’s proprietary data never has to leave its own secure environment. Furthermore, the practice of “data engineering” must be elevated from a one-time project to a critical, ongoing business process. This involves a collaborative “machine + human” model to continuously transform messy, unstructured, and disparate data sources into a high-quality, AI-ready asset. This disciplined approach creates a virtuous, evolutionary closed loop, where better data feeds the models, making them progressively smarter, more accurate, and more professionally attuned to the unique nuances of the enterprise with every use cycle.

Diverse Strategies for Successful Deployment

Real-world case studies from pioneering manufacturers reveal that there is no single, one-size-fits-all strategy for deploying AI; instead, the most effective path depends on an organization’s specific culture, scale, and strategic objectives. One highly effective and increasingly popular method is a “small-step, fast-run” approach. This strategy focuses on securing quick, measurable wins by initially applying AI in areas adjacent to the core production line, such as improving the efficiency of administrative collaboration, optimizing sales support processes, or enhancing internal meeting management. By starting with these lower-risk, high-visibility projects, this approach builds crucial momentum and demonstrates tangible value to stakeholders across the organization. These early successes serve as powerful proof points, fostering broader buy-in and creating the organizational confidence needed to tackle more complex and ambitious AI projects directly within the core manufacturing operations down the line, ensuring a smoother and more sustainable transformation.

In contrast to incremental adoption, some organizations find greater success with a systematic, top-down strategic approach that involves a comprehensive and deliberate redesign of the fundamental “relationship between human and machine intelligence.” This ambitious strategy is typically supported by a robust and dedicated organizational structure, often including a CEO-led AI management committee and targeted talent development programs to upskill the entire workforce. This top-level design is complemented by a bottom-up movement focused on cultural change, driven by initiatives such as mass employee empowerment, gamified AI skills competitions to encourage learning and engagement, and the democratization of access to data and analytical tools. This ensures that every employee feels engaged in and empowered by the transformation. Ultimately, the most effective model often appears to be a hybrid, one that skillfully combines clear, strategic direction from leadership with the agile, department-led innovation that arises from an empowered and technologically equipped workforce.

The Dawn of a New Industrial Intelligence

The aggregated insights from industry leaders culminated in several main findings regarding the application of AI in manufacturing. The successful integration of this technology was less about a single technological breakthrough and more about a holistic, strategic alignment of technology, people, and processes. It became clear that the future of industrial AI resided in the development of specialized, composite intelligent agents built upon open, secure platforms that foster a vibrant ecosystem of domain experts. These agents were envisioned not merely as analytical tools but as active participants in the daily workflow, capable of automating complex engineering tasks and providing real-time, actionable insights directly on the production line. Furthermore, the transformation was recognized as being as much cultural as it was technological. True success required both a top-down strategic vision and a bottom-up movement of employee empowerment. The most effective path forward appeared to be a hybrid model that combined firm strategic direction with agile, department-led innovation. The announcement of new cooperation agreements between platform providers and leading enterprises signaled a broadening acceptance and adoption of this platform-based, ecosystem-driven approach. The core message was consistent: for the manufacturing industry, AI’s profound promise would be fulfilled not in a laboratory or a slide deck, but on the factory floor, where it could be integrated, iterated upon, and used to solve the tangible, complex challenges of making things better, faster, and more intelligently.