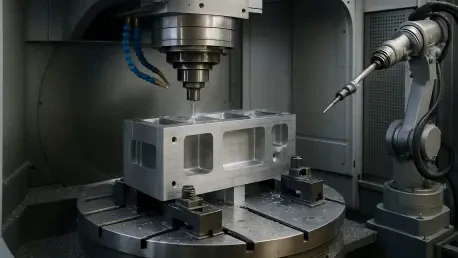

In today’s fast-evolving manufacturing landscape, Computer Numerical Control (CNC) automation emerges as a transformative force, offering the promise of unmatched precision, significant reductions in labor costs, and a substantial boost in operational efficiency. As industries such as aerospace, automotive, and healthcare increasingly rely on intricate components to meet stringent standards, adopting CNC automation is no longer a choice but a critical step for maintaining a competitive edge. However, the journey toward full automation is riddled with challenges that can deter even the most progressive manufacturers. High capital investments, a glaring skills gap, integration difficulties with outdated systems, and ongoing maintenance concerns create a complex web of barriers. Despite these obstacles, emerging technologies and strategic approaches are paving the way for solutions, offering hope to companies striving to modernize. This exploration delves into the core issues hindering adoption and highlights innovative pathways that can help manufacturers navigate these hurdles successfully.

Identifying the Challenges in CNC Automation Adoption

Financial Hurdles

Capital Investment and ROI Concerns

The most immediate barrier to embracing CNC automation lies in the substantial financial commitment it demands, a challenge that hits small and medium-sized enterprises (SMEs) particularly hard. The costs extend far beyond the purchase of sophisticated CNC machinery, encompassing essential software, infrastructure upgrades, and specialized tooling necessary to support these systems. For many, the price tag alone is daunting, often running into hundreds of thousands of dollars before operations even begin. What compounds this financial strain is the uncertainty surrounding return on investment (ROI). Manufacturers face the risk that the anticipated benefits—such as increased productivity or reduced labor expenses—may take years to materialize, if at all, due to unforeseen integration snags or market fluctuations. This hesitation can paralyze decision-making, leaving companies stuck with outdated processes while competitors surge ahead with modernized capabilities.

Economic Strategies for Mitigation

Beyond the sticker shock, manufacturers must grapple with aligning such a significant outlay with long-term business goals, often requiring a leap of faith in an unpredictable economic climate. A potential solution lies in exploring alternative funding models, such as equipment leasing or government-backed loans tailored for industrial upgrades, which can ease the upfront burden. Additionally, focusing on modular CNC systems that allow for incremental investments can help spread costs over time, making the transition less jarring. The key is to conduct thorough cost-benefit analyses that account for not just immediate expenses but also potential savings from reduced waste and enhanced output. By prioritizing projects with quicker payback periods, companies can build confidence in automation, using early successes to justify further investments. This strategic financial planning transforms a seemingly insurmountable barrier into a manageable, step-by-step progression toward modernization.

Workforce Challenges

Addressing the Skills Shortage

One of the most persistent obstacles in adopting CNC automation is the acute shortage of skilled labor capable of operating and maintaining these advanced systems, a problem that affects manufacturers across various regions. Finding individuals proficient in CNC programming, robotics, and complementary technologies like Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) has become increasingly difficult, as educational programs often lag behind industry needs. This skills gap not only delays implementation but also risks underutilizing expensive equipment, as untrained workers struggle with complex tasks. For SMEs with limited resources to attract top talent, this challenge is even more pronounced, often leading to reliance on a small pool of overworked specialists. The resulting inefficiencies can erode the very benefits automation is meant to deliver, creating a frustrating cycle of stalled progress.

Building a Capable Workforce

Tackling the skills shortage requires a multifaceted approach that goes beyond traditional hiring practices to focus on internal development and partnerships. Manufacturers can invest in targeted training programs, collaborating with technical schools or community colleges to design curricula that align with current CNC technologies. Such initiatives not only build a pipeline of qualified workers but also foster loyalty among employees who value professional growth opportunities. Additionally, leveraging online learning platforms for ongoing education can help existing staff upskill without disrupting production schedules. Another avenue is engaging with industry associations to share resources and best practices for workforce development. By cultivating a culture of continuous learning and adaptation, companies can reduce dependency on scarce external talent, ensuring that their teams are equipped to handle the intricacies of modern automation with confidence and competence.

Technical Obstacles

Integration with Legacy Systems

Integrating cutting-edge CNC automation with existing legacy equipment often presents a formidable technical challenge, akin to merging two entirely different technological eras. Many manufacturers operate on systems that predate digital advancements, leading to compatibility issues that can halt production lines and inflate costs. Retrofitting or reconfiguring these older setups to accommodate new CNC machinery is not only time-consuming but also requires significant financial investment, often involving custom solutions or complete overhauls. The risk of prolonged downtime during this transition period adds another layer of complexity, as businesses cannot afford to pause operations in competitive markets. This clash between old and new technologies underscores the need for careful planning and innovative approaches to ensure a seamless shift to automated processes without sacrificing operational continuity.

Maintenance and Downtime Risks

The complexity of modern CNC systems introduces another critical concern: the potential for maintenance issues and costly downtime that can disrupt production schedules. Unlike simpler machinery, these advanced setups rely on intricate software and hardware interactions, making them susceptible to breakdowns that require specialized expertise to resolve. A single malfunction can lead to significant delays, with repair costs and lost productivity quickly adding up, especially for manufacturers operating on tight margins. The fear of such unplanned interruptions often deters companies from fully embracing automation, as the perceived risks can overshadow potential gains. Moreover, the lack of in-house technical know-how to address these issues exacerbates the problem, leaving firms vulnerable to extended periods of inactivity. Addressing these maintenance challenges is crucial for building trust in CNC systems as reliable components of manufacturing operations.

Pioneering Solutions for CNC Automation Success

Technology as a Game-Changer

Harnessing AI and IIoT Innovations

Emerging technologies like Artificial Intelligence (AI) and the Industrial Internet of Things (IIoT) are revolutionizing the way manufacturers approach CNC automation, offering powerful tools to dismantle long-standing barriers. AI enhances operational efficiency by optimizing machining processes, minimizing material waste, and predicting outcomes with remarkable accuracy, thus accelerating ROI for even the most cautious investors. Meanwhile, IIoT facilitates real-time data sharing across connected devices, enabling seamless communication between new CNC systems and existing equipment. This connectivity streamlines workflows, reduces integration hiccups, and provides actionable insights into production performance. Together, these advancements lower the entry threshold for automation, allowing companies of varying sizes to adopt sophisticated systems without the burden of extensive overhauls. The result is a more agile manufacturing environment capable of adapting to market demands with precision and speed.

Predictive Maintenance Breakthroughs

Another transformative solution lies in predictive maintenance, a technology powered by IIoT that addresses one of the most pressing concerns surrounding CNC automation: unexpected downtime. By continuously monitoring equipment performance through sensors and data analytics, predictive tools can identify potential failures before they occur, alerting operators to take preemptive action. This capability significantly reduces the likelihood of costly production halts and extends the lifespan of machinery by ensuring timely interventions. Furthermore, it minimizes maintenance expenses, as repairs are conducted only when necessary rather than on a rigid schedule or after a breakdown. For manufacturers wary of the risks associated with complex systems, this innovation offers a safety net, transforming automation from a gamble into a calculated investment. The adoption of such technology fosters a proactive rather than reactive approach, enhancing overall operational reliability.

Simplifying Operations

User-Friendly Tools and Interfaces

To counter the pervasive skills gap, the development of user-friendly software and intuitive interfaces marks a significant step forward in making CNC automation accessible to a broader workforce. Modern CNC systems now often include AI-driven co-pilots within CAM programs, which guide operators through complex tasks with simplified prompts and automated adjustments. This reduces the learning curve for less experienced workers, enabling them to manage sophisticated equipment with minimal training. Such tools democratize access to automation by lowering the dependency on highly specialized personnel, a critical advantage for SMEs with limited hiring budgets. By focusing on ease of use, these advancements ensure that technology serves as an enabler rather than a barrier, empowering manufacturers to maximize their investments without the constant need for expert intervention.

Strategic Training for Long-Term Success

Complementing technological aids, a renewed emphasis on strategic training programs offers a sustainable solution to workforce limitations in CNC automation. Manufacturers can partner with educational institutions or industry bodies to develop tailored courses that focus on practical, hands-on experience with current systems. These initiatives not only build technical proficiency but also instill confidence in employees to tackle evolving challenges. Additionally, integrating digital training modules allows for flexible learning that accommodates production schedules, ensuring minimal disruption. Over time, such efforts cultivate a skilled internal team capable of driving automation initiatives independently, reducing reliance on external resources. This focus on human capital investment proves to be a cornerstone for companies that have successfully navigated the automation landscape in recent years, reflecting a commitment to balancing technological progress with workforce readiness for enduring growth.