Today, we’re thrilled to sit down with Kwame Zaire, a renowned expert in manufacturing with a deep focus on electronics, equipment, and production management. With his thought leadership in predictive maintenance, quality, and safety, Kwame brings a wealth of insight into the evolving world of additive manufacturing. In this conversation, we explore the remarkable journey of a company celebrating its fifth anniversary and a major milestone of producing its 100,000th additively manufactured implant. We’ll dive into the inspirations behind its founding, the significance of this achievement, innovations in 3D printing, and the strategies behind maintaining top-notch quality and customer satisfaction, all while looking ahead to the future of medical device production.

Can you tell us what sparked the idea to start a company like this back in 2020?

Absolutely. The idea came from a mix of personal passion and a clear gap we saw in the market. My co-founder and I had been working in additive manufacturing for years, and we noticed that while the technology had incredible potential, especially for medical implants, there was a lack of focus on scalability and reliability. We wanted to create a company that could bridge that gap—delivering high-quality, customized implants at a volume that could truly impact the industry. It was about combining innovation with a practical, customer-focused approach.

Hitting the milestone of the 100,000th implant must be incredibly rewarding. How does this achievement feel after just five years?

It’s honestly surreal. When we started, we had ambitious goals, but reaching this number so quickly is a testament to the team’s hard work and our customers’ trust. It feels like validation that we’re on the right path. I think the moment that really hit home for me was when we shipped that 100,000th implant—an FDA-approved device for a key partner. It wasn’t just a number; it was a symbol of how far we’ve come in making a difference in patients’ lives.

Speaking of that 100,000th implant, it was a specialized device for a partner company. Can you share how that collaboration came to life?

Sure, that partnership was a natural fit. We connected with the team through industry networks, and they were looking for a manufacturer who could not only produce a complex sacroiliac fixation device but also help navigate the regulatory landscape. From the start, it was a collaborative effort. We worked closely on the design to ensure it met both clinical and manufacturing requirements, and our shared focus on speed and precision made the project a success. It’s rewarding to see how our combined efforts resulted in a product that’s now helping patients.

Your partner mentioned that working with your company significantly sped up their timeline to market. How did you manage to streamline that process?

A big part of it comes down to our structured approach and deep understanding of regulatory requirements. We’ve built a robust system that anticipates the needs of approvals, especially with the FDA. One key tool is our FDA Master File, which provides a pre-validated framework that our customers can reference. This cuts down on redundant documentation and speeds up the review process. Beyond that, we prioritize clear communication and rapid execution so there’s no wasted time. It’s about removing roadblocks before they even appear.

With a customer acceptance rate over 99.9% and on-time delivery above 90%, your standards are incredibly high. What’s your secret to maintaining such quality and reliability?

It all starts with a culture of accountability and precision. We’ve invested heavily in quality control systems, from rigorous testing at every stage of production to regular audits of our processes. On the delivery side, we use advanced planning tools to manage our workflow and anticipate bottlenecks. But honestly, a lot of it comes down to the team. Everyone is committed to getting it right the first time, whether it’s ensuring an implant meets specs or hitting a tight deadline. We also listen to customer feedback constantly to keep improving.

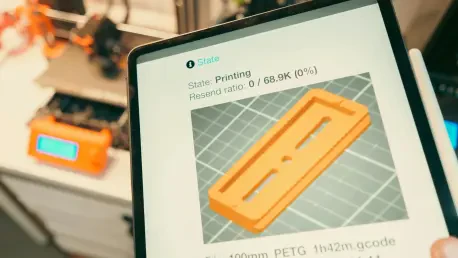

Innovation seems to be at the core of what you do. Can you share an example of how you’ve pushed the boundaries of 3D printing technology?

Definitely. One area I’m really proud of is how we’ve refined the use of specific materials and printing techniques to improve implant performance. For instance, we’ve developed ways to enhance the surface texture of implants using additive manufacturing, which helps with bone integration for patients. Deciding which innovations to pursue often comes from customer needs or gaps we spot in current tech. We’re not just chasing the latest trend; we focus on what can scale and make a real impact in the field. That balance is what drives us.

Looking toward the future, with plans to ship over 50,000 implants in 2025, how are you preparing for that kind of growth?

We’re scaling up in a big way. Right now, we’re expanding our in-house production capacity with new equipment and optimizing our workflows to handle higher volumes without compromising quality. We’re also diversifying into other high-performance applications beyond medical devices, like aerospace and semiconductors, which helps balance our operations. On top of that, we’re investing in training and bringing in more talent to keep up with demand. It’s a challenge, but we’re building on a solid foundation of reliability to make sure we’re ready.

What’s your forecast for the future of additive manufacturing in the medical field over the next decade?

I think we’re on the cusp of a real transformation. Over the next ten years, I expect additive manufacturing to become even more personalized—think implants tailored not just to a patient’s anatomy but to their specific cellular needs using advanced biomaterials. We’ll also see tighter integration of digital tools, like AI, to optimize designs and predict outcomes before anything is printed. Regulatory frameworks will evolve to keep pace with these advancements, hopefully becoming more streamlined. Overall, the focus will be on accessibility—making these cutting-edge solutions available to more patients worldwide. It’s an exciting time to be in this space.