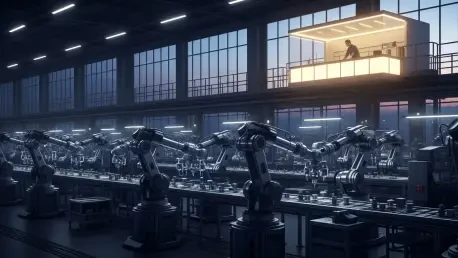

The transition of industrial robots from repetitive, single-task machines into dynamic, intelligent partners is accelerating, representing one of the most significant shifts in modern industry. This evolution is not a spontaneous leap but a carefully cultivated journey, guided by a new paradigm that views robots as systems to be developed through distinct life stages. This structured framework provides a comprehensive roadmap for nurturing artificial intelligence, guiding a robotic system from a digital concept through a real-world apprenticeship and into a state of continuous, adaptive learning. By following this developmental progression, organizations can systematically overcome the primary obstacles of safety, data scarcity, and prohibitive integration costs that have historically impeded the scalable implementation of AI in demanding industrial environments such as manufacturing, logistics, and supply chain management. This approach reimagines automation, transforming it from a simple capital expenditure into a long-term investment in a collaborative, ever-improving partner.

The Three-Stage Evolutionary Journey

The First Life Birth in the Digital World

The journey of an advanced industrial robot begins not with the assembly of physical components on a factory floor, but as pure information within a meticulously crafted digital simulation. This “first life” serves as a controlled and risk-free incubator, where the robot’s nascent AI is exposed to an exhaustive training regimen. Within this virtual crucible, the system can learn to navigate complex, hazardous, or exceptionally rare scenarios without any possibility of causing physical damage, incurring operational downtime, or endangering human personnel. For instance, an AI can be trained to handle a catastrophic equipment failure or manage a delicate chemical process thousands of times, achieving a level of proficiency and safety that would be impossible to attain through real-world trial and error. This initial phase is fundamentally about de-risking the integration of AI. It allows for the development of a mature and capable intelligence before it is ever connected to expensive, mission-critical hardware, ensuring that when the robot is physically deployed, it already possesses a deep foundational understanding of its tasks and operational environment.

This simulation-based training provides a powerful solution to one of industrial AI’s most persistent and fundamental challenges: the scarcity of high-quality training data. Traditionally, training an AI for a task like visual defect detection would require a massive and often unobtainable dataset, including thousands of physical examples of both perfect products and every conceivable flaw. This is particularly impractical in high-quality manufacturing, where defects are rare by design. The digital approach circumvents this limitation entirely through the use of synthetic data generation. Within the virtual environment, developers can create a nearly infinite stream of perfectly labeled data, simulating countless variations in lighting conditions, material textures, component irregularities, and potential operational failures. This method is not only dramatically more cost-effective than physical data collection but also produces a more robust and comprehensive training set. As a result, the AI is better prepared for the variability of the real world, leading to a more reliable and effective system from the moment of its physical activation.

The Second Life Apprenticeship in the Real World

Following its comprehensive education in the digital realm, the robot enters its second lifecycle, a critical transitional period that can be likened to an apprenticeship. This stage is dedicated to bridging the “simulation-to-reality gap”—the performance discrepancy that often arises when an AI trained exclusively on simulated data encounters the unpredictable and nuanced variables of the physical world. No matter how sophisticated a simulation is, it cannot perfectly replicate every aspect of reality, from the subtle friction of a specific surface to the unpredictable ways light reflects off a polished component. This phase, therefore, focuses on refining the robot’s learned behaviors and adapting its digital knowledge to the tangible environment it now inhabits. It represents the point where theoretical understanding is tested and honed through practical application, a necessary step to ensure the robot can perform its duties reliably and efficiently in a dynamic, non-ideal setting.

The key to successfully navigating this stage is the direct transfer of knowledge from human experts to the machine. Rather than rendering human workers obsolete, this framework elevates them to the indispensable role of mentors and trainers. Using intuitive methods such as remote operation, learning by demonstration, or kinesthetic teaching—where an experienced operator physically guides a robotic arm through a complex assembly process—human expertise is captured and translated into machine-learnable data. The robot’s AI meticulously records these demonstrations as “state-action pairs,” correlating the sensory data it perceives from its environment with the precise actions taken by its human trainer. This process of direct, hands-on instruction allows the robot to learn the subtle, instinctual skills that are difficult, if not impossible, to codify in traditional programming. It is a collaborative process that not only accelerates the robot’s learning but also addresses a key barrier to AI adoption: the lack of employee readiness. By empowering the existing workforce to train their robotic counterparts, organizations foster a symbiotic relationship, transforming a programmed machine into a generalist partner capable of adapting its skills across a variety of tasks.

The Third Life Maturity into a Collaborative Partner

The final and most advanced stage of the framework marks the robot’s maturation into a fully adaptive and continuously learning partner. This “third life” is what truly distinguishes advanced robotics from basic automation, which is typically characterized by the endless, static repetition of a fixed task. A robot that has reached this level of development is no longer simply executing a pre-written program; it is an intelligent agent engineered to constantly refine its performance and adapt to changing conditions within its operational environment. If a new material is introduced on the production line, or if the ambient lighting in the facility changes, a traditional robot would likely fail or require extensive reprogramming. A third-life robot, by contrast, perceives these changes, adjusts its methods, and continues to operate effectively, often improving its own processes without direct human intervention. This capability transforms the robot from a depreciating tool into a long-term asset whose value and utility increase over time.

The engine driving this continuous improvement is a sophisticated methodology known as Reinforcement Learning from Human Feedback (RLHF). In this model, the robot continues its on-the-job training indefinitely, and human experts provide ongoing, high-level feedback to guide its development. Instead of reprogramming the machine, a human supervisor might simply rank or compare the outcomes of the robot’s different operational attempts, providing positive or negative reinforcement that the AI uses to progressively improve its methods. This interactive feedback loop allows the AI to optimize its actions for efficiency and quality, and even to develop novel solutions to problems that its human trainers may not have anticipated. The economic implications are profound. A system with this level of adaptability can be redeployed and retrained for new tasks with minimal downtime, tackling the integration challenges that often plague industrial automation projects. This is the point where the robot transcends its function as a tool and becomes an integral, intelligent part of front-line operations, delivering measurable and ever-increasing economic benefits through accumulated experience and adaptation.

Overcoming the Hurdles on the Path to Partnership

Navigating the Implementation Challenges

The successful implementation of this evolutionary framework hinges on surmounting several significant technical barriers, the most critical of which is the quality and fidelity of the initial digital simulation. The entire lifecycle is built upon the foundation laid in the robot’s “first life,” and if that foundation is flawed, the subsequent stages will inevitably falter. Low-quality or biased data injected into the virtual training environment will lead to an unreliable AI, and if the simulation does not accurately mirror the physics, lighting, and material properties of the real world, the “simulation-to-reality gap” will become an insurmountable chasm. Organizations must therefore recognize that creating a high-fidelity digital twin of their operational environment is not an optional expense but a foundational investment. This requires a deep commitment to gathering accurate data and developing sophisticated models that can genuinely prepare the AI for the complexities it will face upon physical deployment.

Beyond the technical requirements, the transition to a collaborative human-robot workforce presents profound organizational and cultural challenges. While the framework leverages human expertise, it also demands a significant shift in the workforce’s skillset. The successful adoption of this model is less about replacing human labor and more about evolving it; employees must be trained to become effective robot trainers, data annotators, and collaborators. This requires developing new training programs and fostering a culture that embraces human-robot interaction. Furthermore, the transition points between each lifecycle represent critical and complex integration stages. Even with a high-quality simulation and expert human guidance, unforeseen real-world variables can cause performance degradation. Organizations must explicitly plan and budget for these transitions, implementing robust feedback mechanisms and real-time correction systems to ensure a smooth and continuous learning curve for their evolving robotic partners.

A Conclusive Shift in Industrial Strategy

The analysis of this developmental lifecycle revealed a clear and structured pathway for transforming industrial robots from single-purpose tools into adaptable, intelligent partners. It was understood that this evolution was not merely a technological upgrade but a fundamental strategic shift, requiring a holistic approach that encompassed simulation, apprenticeship, and continuous learning. The framework provided a practical methodology for cultivating AI systems that were not only powerful but also inherently safer, more collaborative, and economically sustainable over the long term. This structured journey directly addressed the most significant barriers to AI adoption by mitigating risks in a virtual environment, leveraging existing human expertise for real-world adaptation, and engineering systems designed for perpetual improvement.

Looking back on this model, its alignment with the broader structural changes occurring across industry became evident. The convergence of advanced AI, innovative hardware, and modern manufacturing platforms was already transforming robots from specialized instruments into “generalist partners.” These mature, third-life robots embodied the concept of agent-based AI systems—autonomous entities capable of making complex decisions and collaborating effectively with both human and artificial colleagues. Ultimately, it was concluded that the future of industry would be defined not by the companies that simply purchased robots, but by those that invested in nurturing them through their entire evolutionary lifecycle. Successfully navigating this path demanded more than capital investment; it required a comprehensive strategy that integrated technology with governance, compliance, and, most critically, workforce development, paving the way for a future where humans and robots worked in concert to solve the most difficult industrial challenges.