Orlando Ely, a young entrepreneur, has developed an innovative therapeutic device called Blossom, integrating advanced manufacturing techniques and 3D printing to aid stroke recovery. Inspired by personal experiences witnessing family members suffer from strokes, Ely’s device aims to enhance fine motor skills and cognitive functions. His journey from home-based prototyping to advanced manufacturing collaboration turns Blossom into a viable product for mass production.

Bridging Personal Experience and Innovation

The Inspiration Behind Blossom

Ely’s motivation to create Blossom sprang from witnessing two close family members suffer strokes. Recognizing the need for effective and stimulating rehabilitation tools, he envisioned a device that spurred recovery through creative and engaging activities. His personal connection to stroke rehabilitation drove him to innovate beyond traditional methods, seeking a solution that combines physical and cognitive therapy in a novel way. This intimate understanding of the challenges faced by stroke survivors gave Ely a unique perspective and determination to create Blossom.

Through rigorous research and countless iterations, Ely designed Blossom to meet the specific needs of stroke patients. The device features three buildable flowers, each presenting progressively challenging tasks to users. By incrementally increasing the difficulty, Blossom aims to improve fine motor skills and cognitive function. The nature-inspired design is not just aesthetically pleasing but also psychologically beneficial, as it promotes a positive and engaging rehabilitation experience. Ely’s personal dedication to the project is a testament to the device’s potential effectiveness in stroke recovery.

Designing for Cognitive and Physical Rehabilitation

Blossom features three buildable flowers that progressively challenge users’ motor skills. This nature-inspired design promotes both physical rehabilitation and cognitive engagement, enhancing users’ mood and motivation. Each flower requires different manipulative techniques, engaging various hand muscles and motor pathways in the brain. The repetitive action of assembling and disassembling the flowers helps rewire neural connections, a crucial aspect of stroke recovery. This harmonious blend of physical and mental tasks makes Blossom a holistic and multifaceted therapeutic tool.

The design’s focus on patterns and sensory stimulation is key to its success. By incorporating elements such as varying petal layouts and textures, Blossom provides a stimulating and rewarding experience. As users progress through the three flower levels, they not only refine their motor skills but also gain confidence and more profound cognitive function. This dual approach ensures that therapy remains engaging, reducing the monotony often associated with rehabilitation exercises. Consequently, Blossom helps to maintain patient adherence to prescribed therapeutic regimens, significantly enhancing recovery outcomes.

Collaboration with Experts

From Home Prototypes to Professional Input

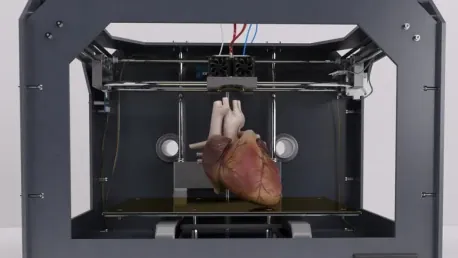

Initially developed using an at-home 3D printer, Blossom’s design matured through collaboration with the National Manufacturing Institute Scotland (NMIS). Engaging experts helped refine the design, identifying suitable materials and manufacturing methods. Ely’s partnership with NMIS brought professional insight into the creative process, allowing him to move beyond the limitations of home-based prototyping. The NMIS involvement provided access to advanced manufacturing technologies and a wealth of expertise in material science and production techniques.

This collaboration marked a significant turning point for Blossom. The detailed 3D modeling sessions allowed for optimizing the design’s structural integrity and functional performance. Discussions with manufacturing experts helped to choose the best materials for durability and user comfort. Moreover, NMIS’s involvement ensured that the product was ready for mass production, ultimately making it more accessible to a wider audience. The transition from a home-printed prototype to a professionally manufactured product underscored the viability and market potential of Blossom.

Exploring Advanced Manufacturing Techniques

Various manufacturing techniques were evaluated, including injection molding and additive manufacturing methods such as Powder Bed Fusion (PBF). PBF was chosen for its ability to produce strong, durable parts with a necessary textured finish for usability. The NMIS team also introduced a dimple fastening method to enhance the sensory experience. This advanced manufacturing approach allowed for precision and customization, essential for optimizing the therapeutic benefits of Blossom. Each flower had to be produced with exacting standards to ensure consistency and effectiveness in therapy.

The PBF process facilitated the production of intricate designs and complex geometries that would be challenging to achieve through traditional manufacturing methods. The ability to create bespoke textures and fine details ensured that each Blossom unit met the high standards required for medical devices. This choice of manufacturing technique not only improved the product’s functional aspects but also its aesthetic appeal. The textured surfaces and refined design elements catered to both user comfort and engagement, integral aspects of successful rehabilitation tools.

Perfecting the Prototype

Collecting Detailed User Feedback

Clinical consultations and trials with dementia groups played a crucial role in refining Blossom’s prototype. Feedback from these sessions provided insights to make necessary adjustments, ensuring the device meets users’ needs effectively. Engaging with healthcare professionals and caretakers allowed Ely to gather valuable data on the device’s real-world application. These interactions highlighted specific areas for improvement, enabling the iterative enhancement of Blossom to better suit the therapeutic landscape.

User feedback was instrumental in addressing the device’s ergonomic and functional aspects. Observations from trials revealed the importance of making the flowers easy to grasp and manipulate while providing enough resistance to challenge users’ motor skills. Adjustments based on this feedback included refining the flower shapes, modifying material textures, and improving the interlocking mechanisms. These changes ensured that Blossom not only met therapeutic goals but also provided a comfortable and rewarding user experience. This iterative process exemplified the importance of patient-centric design in medical device development.

Enhancing Aesthetic and Therapeutic Appeal

A key goal is to enhance Blossom’s aesthetic appearance while expanding its therapeutic applications. The sophisticated design, drawing on scientific principles such as phyllotactic patterns, aims to make the tool appealing to a wider audience and encourage consistent use. The incorporation of these natural patterns not only adds a visual charm but also ensures that the device maintains therapeutic efficacy. The aesthetic design is crucial for user retention, as it motivates patients to engage with the device regularly, an essential factor in successful rehabilitation.

Expanding the therapeutic applications of Blossom involves exploring its use in various clinical settings and with different patient groups. While initially focused on stroke recovery, the principles underlying its design can be adapted for other cognitive and motor impairment therapies. This flexibility opens new avenues for application in broader medical fields, potentially aiding in the treatment of conditions such as dementia and traumatic brain injuries. By continuously refining and evolving the device, Ely aims to establish Blossom as a versatile and effective tool in the broader context of medical rehabilitation.

Impacting the Future of Rehabilitation Devices

Supporting Emerging Businesses

Ely’s journey underscores the support available for emerging businesses. Through collaboration with NMIS, innovative ideas can be optimized and brought to market, showcasing the potential of modern manufacturing techniques. This partnership exemplifies the critical role that institutional support plays in transforming groundbreaking ideas into commercially viable products. The mentorship, resources, and technological expertise provided by NMIS equipped Ely with the tools necessary to navigate the complexities of product development and manufacturing.

The success of Blossom highlights the broader implications for other entrepreneurs and innovators in the medical device field. It demonstrates how emerging businesses can leverage advanced manufacturing techniques and institutional support to bring their ideas to fruition. This collaborative model fosters innovation, encourages entrepreneurship, and accelerates the development of cutting-edge medical technologies. By providing a blueprint for similar initiatives, Ely’s experience serves as a motivating example for others aspiring to make impactful contributions to healthcare.

Advanced Manufacturing and Market Trends

Blossom not only exemplifies advanced manufacturing’s capabilities but also aligns with broader trends in medical rehabilitation. Techniques like biodegradable polymers and micromolding in medical device production point towards a future of sustainable and efficient medical solutions. The integration of these advanced materials and methods underscores the industry’s shift towards more environmentally responsible and cost-effective manufacturing practices. This trend is driven by the need to produce high-quality medical devices while minimizing environmental impact.

The market growth for biodegradable polymers, coupled with advancements in recycling and dissolution technologies for plastics, signals a promising future for sustainable medical devices. These eco-friendly innovations are increasingly being adopted in the production of medical tools, reflecting a broader commitment to sustainability within the industry. Blossom’s development and manufacturing processes resonate with these emerging trends, positioning it at the forefront of modern rehabilitation devices. By aligning with these market dynamics, Ely ensures that Blossom remains relevant and competitive, paving the way for future innovations in medical device manufacturing.

Blossom in the Context of Modern Rehabilitation

Integrating Sophistication and Functionality

Unlike existing therapy tools that can feel juvenile, Blossom combines the beauty of flowers with the functionality of rehabilitation exercises. This dual approach ensures aesthetic appeal and therapeutic effectiveness. The sophisticated design not only engages users visually but also provides the necessary physical challenges for effective therapy. By merging these elements, Blossom addresses the psychological and physiological aspects of recovery, making it a comprehensive rehabilitation tool.

The integration of phyllotactic patterns and the careful consideration of sensory experiences set Blossom apart from conventional therapy devices. These design elements foster a more enjoyable and immersive rehabilitation process, enhancing user adherence and outcomes. The elegance and functionality of Blossom reflect a thoughtful approach to medical device design, prioritizing both user experience and therapeutic efficacy. This innovative blend of art and science exemplifies how modern rehabilitation tools can transcend traditional limitations, offering patients a more dignified and effective path to recovery.

Exploring Broader Therapeutic Applications

Orlando Ely, a dynamic young entrepreneur, has created an innovative therapeutic device called Blossom, which utilizes cutting-edge manufacturing techniques and 3D printing to aid in stroke recovery. The inspiration behind Blossom came from Ely’s personal experiences, observing loved ones struggle with the aftermath of strokes. Motivated to make a difference, he focused on developing a device that could significantly improve fine motor skills and cognitive functions for stroke survivors. Ely’s journey began with home-based prototyping, fueled by a deep commitment to his mission. As his project progressed, he sought collaborations with experts in advanced manufacturing to transform Blossom from a mere prototype into a market-ready product capable of mass production. Through perseverance and a vision to enhance the quality of life for stroke victims, Ely successfully bridged the gap between innovation and practical application, ultimately making a meaningful impact on stroke recovery.