In an era where manufacturing is no longer just about producing goods but doing so smarter and faster, a groundbreaking shift is reshaping the industry through the integration of Information Technology (IT) and Operational Technology (OT). This powerful fusion, often termed IT-OT convergence, merges the digital intelligence of data analytics with the physical grit of production machinery, creating a synergy that redefines operational excellence. Picture a factory where real-time data streams effortlessly from shop floor sensors to executive dashboards, enabling split-second decisions that prevent downtime or optimize resources. This isn’t a distant vision but a reality that’s driving efficiency, sustainability, and market competitiveness for forward-thinking manufacturers. As digital transformation becomes the backbone of industrial success, understanding this convergence is crucial for any player aiming to stay relevant in a rapidly evolving landscape.

The implications of blending IT and OT extend far beyond mere technological upgrades. This integration represents a fundamental change in how factories operate, breaking down silos between strategic planning and hands-on execution. It empowers manufacturers to anticipate issues before they escalate, adapt to market fluctuations with agility, and align with pressing goals like sustainability. However, the journey is not without obstacles, as cybersecurity threats, aging infrastructure, and skill shortages pose significant challenges. Exploring the mechanics, benefits, and hurdles of this trend reveals why it’s not just an option but a strategic necessity for survival in today’s cutthroat market.

Understanding IT-OT Convergence

Defining the Integration Mechanics

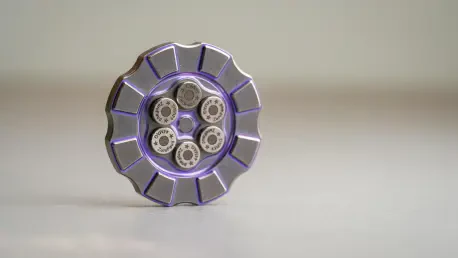

At the core of modern manufacturing innovation lies the seamless connection between IT systems, which manage data analytics and enterprise strategies, and OT systems, which control physical production through hardware like IoT sensors and programmable logic controllers (PLCs). This convergence creates a unified flow of information, allowing data collected from machinery on the shop floor to inform high-level business decisions in real time. Technologies such as digital twins play a pivotal role by providing virtual replicas of physical assets, enabling simulations that predict outcomes without risking actual resources. The result is a heightened level of visibility across operations, where every process, from assembly to maintenance, can be monitored and optimized with precision. This integration isn’t merely about connecting systems but about creating a responsive ecosystem that thrives on continuous feedback and improvement.

Beyond the technical linkage, the mechanics of IT-OT convergence hinge on advanced frameworks like unified architectures and edge computing. These tools ensure that data isn’t just collected but processed close to its source for faster decision-making, minimizing latency that could disrupt production. For instance, when a sensor detects a potential equipment failure, the data is analyzed instantly, triggering automated alerts or adjustments without waiting for centralized approval. This level of responsiveness transforms factories into dynamic environments where inefficiencies are caught early, and opportunities for enhancement are seized promptly. The focus remains on building a cohesive system where digital and physical worlds don’t just coexist but actively enhance each other’s capabilities.

Real-World Applications in Factories

The practical applications of IT-OT convergence are evident in how manufacturers leverage real-time data to overhaul traditional workflows. Consider a scenario where production lines are equipped with IoT devices that track every stage of assembly, feeding information into IT systems for analysis. If a bottleneck emerges, managers are alerted instantly through integrated dashboards, allowing for swift interventions that keep schedules on track. This isn’t a hypothetical advantage but a tangible shift seen across industries, from automotive to consumer goods, where downtime is slashed by integrating operational insights with strategic oversight. The ability to act on data as it’s generated marks a departure from reactive problem-solving to a proactive stance that prioritizes prevention over cure.

Another compelling application lies in quality control, where IT-OT integration ensures that defects are identified and addressed before products leave the factory floor. Sensors embedded in machinery detect anomalies in real time, while IT software correlates this data with historical patterns to pinpoint root causes. This synergy not only reduces waste but also ensures compliance with stringent industry standards, safeguarding brand reputation. Manufacturers adopting this approach find themselves better equipped to meet customer expectations while maintaining cost efficiency. By embedding digital intelligence into physical processes, factories evolve into smart ecosystems where every component works in harmony to deliver consistent, high-quality output.

The Transformative Benefits

Driving Efficiency and Agility

One of the most striking advantages of IT-OT convergence is its impact on operational efficiency, particularly through predictive maintenance. By harnessing real-time data from OT systems, manufacturers can anticipate equipment failures before they occur, reducing unplanned downtime by significant margins—often reported as high as 40%. This isn’t just about fixing machines; it’s about using IT analytics to schedule maintenance during non-peak hours, ensuring production lines keep humming. The integration also streamlines automation, cutting operational costs by optimizing workflows and minimizing manual intervention. Such advancements enable factories to produce more with less, positioning them as leaders in cost-effective manufacturing without sacrificing quality.

Equally transformative is the agility that IT-OT convergence injects into decision-making processes. With tools like edge computing, critical choices are made closer to the production source, slashing response times to market shifts or internal disruptions. When demand spikes unexpectedly, integrated systems allow for rapid reconfiguration of production schedules, ensuring supply meets demand without overstocking. This nimbleness is further enhanced by machine learning algorithms that analyze historical data to forecast trends, enabling proactive adjustments. Manufacturers gain the flexibility to pivot strategies swiftly, whether addressing a sudden raw material shortage or capitalizing on a new customer trend, cementing their ability to stay ahead in a volatile market.

Boosting Sustainability and Resilience

Sustainability emerges as a key beneficiary of IT-OT convergence, as manufacturers harness integrated data to minimize environmental impact. Real-time monitoring of energy consumption across production lines allows for precise identification of inefficiencies, enabling targeted optimizations that reduce waste. For instance, digital twins can simulate energy usage scenarios, helping to design processes that align with net-zero goals. This isn’t merely about compliance with regulations but about building a reputation as a responsible corporate citizen, appealing to eco-conscious consumers and investors. By aligning operational efficiency with green initiatives, factories contribute to broader sustainability targets while often realizing cost savings from reduced resource use.

Resilience, another critical outcome, is strengthened through the ability of IT-OT systems to provide early warnings for potential disruptions. Real-time data from supply chain touchpoints, combined with IT-driven analytics, flags issues like shipping delays or component shortages before they halt production. This foresight allows for contingency plans to be activated swiftly, such as sourcing alternative suppliers or rerouting logistics. Additionally, integrated monitoring helps mitigate risks from external threats like cyberattacks by identifying unusual activity in OT environments. Manufacturers equipped with such capabilities are better prepared to weather crises, ensuring continuity even in the face of global uncertainties, and maintaining trust with stakeholders through consistent delivery.

Overcoming the Challenges

Tackling Security and Infrastructure Issues

As IT-OT convergence deepens connectivity across manufacturing systems, it also amplifies cybersecurity risks that cannot be overlooked. With operational environments increasingly linked to digital networks, vulnerabilities emerge, making factories prime targets for attacks that can disrupt production or compromise sensitive data. Adopting robust solutions like zero-trust architectures, which verify every user and device before granting access, becomes essential to safeguard against threats. Endpoint protection and regular security audits further fortify defenses, ensuring that the benefits of integration aren’t undermined by breaches. Addressing these risks head-on is critical to maintaining operational integrity and protecting intellectual property in a connected industrial landscape.

Another formidable challenge lies in the outdated infrastructure that many manufacturers still rely on, often incompatible with modern IT-OT integration demands. Legacy systems, designed for isolated operations, struggle to support the seamless data flow required for convergence, leading to inefficiencies or integration failures. Solutions like event-driven architectures and modular upgrades offer a path forward, allowing gradual modernization without the need for costly overhauls. By prioritizing interoperability through standardized protocols, manufacturers can bridge the gap between old and new, ensuring that even aging facilities can tap into the advantages of connected systems. This strategic approach to infrastructure modernization is vital for a smooth transition to a fully integrated future.

Bridging Cultural and Skill Gaps

The human element presents a significant barrier to IT-OT convergence, particularly the cultural divide between IT and OT teams who often operate with distinct priorities and mindsets. IT professionals typically focus on long-term data strategies, while OT staff prioritize immediate production uptime, leading to friction in collaborative efforts. Forming multidisciplinary teams that blend expertise from both domains helps to align goals, fostering a shared understanding of how integration serves the broader organization. Encouraging open communication and joint problem-solving initiatives further dismantles silos, creating a unified workforce capable of driving convergence from the ground up. This cultural alignment is as crucial as any technological solution in achieving lasting success.

Compounding the cultural challenge is the persistent shortage of skilled talent equipped to manage hybrid IT-OT environments, especially in areas like artificial intelligence and IoT applications. Many manufacturers find themselves competing for a limited pool of experts, which can delay or derail integration projects. Partnering with educational institutions or specialized training providers offers a viable solution, equipping existing staff with the necessary competencies to handle converged systems. Additionally, deploying user-friendly tools that simplify complex processes can empower non-specialists to contribute effectively. Addressing these skill gaps ensures that technological advancements are matched by human capability, paving the way for sustainable progress in manufacturing transformation.

The Competitive Imperative

Staying Ahead in a Digital Era

In a market where digital transformation dictates success, IT-OT convergence stands as a non-negotiable for manufacturers aiming to maintain a competitive edge. Industry forecasts indicate that within the next few years, a substantial majority of leading industrial organizations will adopt integrated strategies to accelerate product development cycles and enhance operational performance. Those who hesitate to embrace this shift risk obsolescence, as competitors leverage real-time data and digital tools to innovate faster and respond more effectively to customer needs. This isn’t merely about keeping up but about redefining market leadership through a commitment to technological integration that reshapes every facet of production.

The strategic importance of IT-OT convergence extends to fostering innovation that sets industry benchmarks. Manufacturers who integrate these domains can pioneer new approaches, such as using virtual simulations to test product designs before physical prototyping, slashing time-to-market. This capability not only boosts profitability but also positions companies as trailblazers in a landscape where consumer expectations evolve rapidly. The urgency to adopt this integration is clear: it’s a pathway to not just surviving but thriving amid digital disruption. By prioritizing convergence, manufacturers secure a future where adaptability and foresight become their strongest assets against an ever-changing industrial backdrop.

Building a Future-Ready Foundation

Looking back, the journey of IT-OT convergence reflected a determined push to overcome initial resistance and technical barriers, setting a precedent for how industries adapted to digital imperatives. Manufacturers who tackled early challenges like cybersecurity vulnerabilities and skill shortages laid the groundwork for robust, integrated systems that became indispensable. Their efforts in aligning IT and OT teams fostered a culture of collaboration that proved essential for sustained innovation. Reflecting on those strides, it’s evident that the commitment to blending digital and physical operations redefined operational benchmarks, turning potential obstacles into stepping stones for progress.

Moving forward, the focus should shift to scalable solutions that ensure long-term resilience and growth. Investing in modular technologies that adapt to future advancements will prevent the pitfalls of obsolescence, while continuous training programs can keep workforces ahead of emerging skill demands. Manufacturers must also prioritize partnerships with tech providers to access cutting-edge tools like advanced digital twins for deeper operational insights. By embedding sustainability into convergence strategies, such as optimizing energy use through real-time data, companies can align with global environmental goals. These actionable steps, built on past lessons, offer a clear roadmap to not only sustain the benefits of integration but to expand them, ensuring manufacturing remains a powerhouse of innovation and responsibility.