In the fast-evolving landscape of smart manufacturing, where precision and efficiency are paramount, a groundbreaking advancement from the Korea Advanced Institute of Science and Technology (KAIST) is making waves with its innovative approach to defect detection. Unveiled on August 26, this cutting-edge artificial intelligence (AI) technology, known as TA4LS (Time-series Domain Adaptation for Mitigating Label Shifts), addresses a persistent challenge in industrial AI: maintaining accuracy when manufacturing conditions inevitably change. Traditional models often falter under shifts in equipment, environmental factors, or production patterns, requiring expensive and time-consuming retraining. KAIST’s solution promises to transform this dynamic by ensuring adaptability without such burdens. Showcased at the esteemed ACM SIGKDD Conference on Knowledge Discovery and Data Mining (KDD), this development not only strengthens smart factories but also hints at broader applications in sectors like healthcare and infrastructure. This exploration delves into the intricacies of TA4LS and its potential to redefine industrial AI.

Overcoming the Barrier of AI Adaptability

The integration of AI into manufacturing has revolutionized quality control, yet a significant obstacle persists in ensuring these systems remain effective amid changing conditions. Traditional defect detection models are built on static datasets, meaning any alteration in factors such as machine upgrades, temperature variations, or production speeds can disrupt data distribution and defect patterns, often termed label shifts. Such discrepancies lead to unreliable predictions, compelling manufacturers to undertake the arduous and costly process of retraining their AI systems. This recurring need for updates hampers operational efficiency and inflates expenses, posing a substantial barrier to the seamless adoption of AI in dynamic factory environments. KAIST’s research directly targets this issue, introducing a method that allows AI to adapt fluidly to new conditions, thereby preserving accuracy without the constant need for overhauls. This approach marks a significant leap forward in addressing a critical pain point for industries reliant on precision.

Further examination of this challenge reveals the broader implications for smart manufacturing as a whole. When AI models fail to adapt, the ripple effects extend beyond mere inaccuracies in defect detection to include increased downtime and compromised product quality, which can erode consumer trust and inflate operational costs. Industries like semiconductor production, where even minute errors can lead to substantial losses, are particularly vulnerable to these setbacks. KAIST’s innovative framework offers a lifeline by mitigating the impact of label shifts, ensuring that AI systems can evolve alongside the factory floor’s ever-changing landscape. By reducing dependency on retraining, this technology not only saves time but also aligns with the industry’s push toward greater automation and resilience. The ability to maintain performance under varying conditions could redefine standards for AI deployment, setting a new benchmark for reliability in high-stakes manufacturing sectors.

Exploring the Core of TA4LS Technology

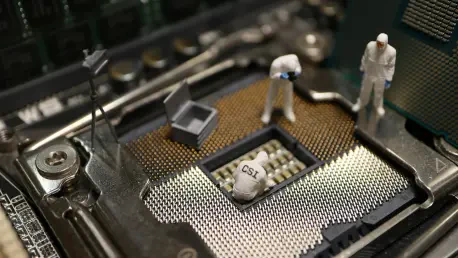

At the heart of KAIST’s transformative contribution lies the TA4LS system, a pioneering time-series domain adaptation technology engineered to enhance how AI interprets complex data. This system innovatively dissects sensor information into distinct components—trends, non-trends, and frequencies—emulating the intuitive way human operators identify irregularities through sensory inputs like sound or vibration shifts. This sophisticated, multi-dimensional analysis empowers the AI to detect defects with remarkable precision, even when the surrounding conditions diverge significantly from those of the initial training phase. By enabling such adaptability, TA4LS ensures that the AI remains relevant and effective, sidestepping the pitfalls that typically plague traditional models during environmental or operational changes. This nuanced approach to data processing represents a significant stride in mimicking human-like anomaly detection within automated systems.

Beyond its analytical capabilities, TA4LS introduces a dynamic mechanism for self-correction that further solidifies its standing as a breakthrough in industrial AI. The system continuously compares its existing predictions against newly clustered data, identifying and adjusting for biases linked to outdated defect patterns. This automatic recalibration aligns the AI with current production realities, eliminating the labor-intensive need to retrain models from scratch whenever conditions shift. Such functionality is particularly valuable in fast-paced manufacturing settings where delays can be costly. The ability of TA4LS to maintain high accuracy through these adaptive processes underscores its potential to become a cornerstone of smart factory operations. As industries increasingly rely on real-time data for decision-making, this technology’s capacity to evolve without interruption offers a compelling solution to longstanding challenges in maintaining AI relevance.

Facilitating Adoption with Seamless Design

One of the standout features of TA4LS is its practical design as a plug-and-play module, crafted to integrate effortlessly with pre-existing AI frameworks in manufacturing setups. Unlike alternative solutions that demand a complete overhaul of current systems, this add-on approach significantly lowers the threshold for adoption, allowing manufacturers to enhance their defect detection capabilities without substantial investments in redevelopment. Experimental trials across four benchmark datasets have demonstrated the system’s efficacy, revealing accuracy improvements of up to 9.42% over conventional methods, particularly in environments marked by pronounced label shifts. This ease of implementation is especially crucial for industries navigating low-volume, high-variety production scenarios, where flexibility and rapid adaptation are non-negotiable for maintaining competitive edges.

Additionally, the user-friendly nature of TA4LS addresses a common concern among manufacturers hesitant to embrace new technologies due to integration complexities. By offering a solution that dovetails with established systems, KAIST has crafted a pathway for widespread adoption that minimizes disruption to ongoing operations. The impressive performance metrics from testing phases further validate the system’s reliability, providing concrete evidence of its ability to outperform traditional models in challenging conditions. This compatibility not only saves resources but also accelerates the transition to smarter, more adaptive manufacturing processes. As industries grapple with the need for scalable AI solutions, the straightforward integration of TA4LS positions it as an attractive option for companies aiming to modernize without the burden of extensive system redesigns, paving the way for broader technological advancements.

Driving Economic and Operational Gains

The economic advantages of TA4LS extend far beyond its technical innovations, offering manufacturers a tangible way to reduce costs while boosting operational efficiency. By negating the need for frequent retraining, the system curtails both maintenance expenses and production downtime, enabling factories to sustain high-quality output without straining budgets. Enhanced defect detection accuracy also translates to fewer errors escaping scrutiny, which in turn bolsters product reliability and minimizes waste. For sectors where precision is critical, such as electronics or automotive manufacturing, these improvements can lead to significant savings and stronger market positioning. KAIST’s technology thus emerges as a cost-effective avenue for scaling AI applications, directly addressing a major hurdle in industrial automation with a solution that prioritizes both fiscal prudence and performance.

Moreover, the operational benefits of TA4LS resonate with the broader goals of smart manufacturing, where the drive for efficiency often intersects with the need for robust quality control. The system’s ability to maintain consistent performance amid fluctuating conditions ensures that production lines operate smoothly, even under unforeseen challenges. This reliability reduces the risk of costly interruptions and enhances overall throughput, a critical factor for industries facing tight deadlines and high demand. By streamlining defect detection processes, TA4LS supports a leaner, more agile approach to manufacturing that aligns with modern industrial imperatives. As companies seek to optimize resources in an increasingly competitive landscape, the financial and operational uplifts provided by this technology underscore its value as a transformative tool for the future of factory automation.

Broadening the Scope of AI Applications

While the primary arena for TA4LS lies within smart manufacturing, its potential reaches far beyond the factory floor, promising impactful applications across diverse sectors. Fields such as healthcare, where AI is increasingly used to monitor medical devices for irregularities, stand to gain from the adaptive capabilities of time-series domain adaptation. Similarly, urban infrastructure management could leverage this technology to detect wear and anomalies in critical systems like bridges or transit networks, enhancing safety and longevity. The versatility of TA4LS highlights its role as a foundational innovation, capable of addressing dynamic challenges in any domain where responsive AI is essential. This expansive applicability signals a shift toward broader AI integration, where adaptability becomes a universal benchmark for system design.

Furthermore, the cross-industry potential of TA4LS reflects a growing recognition of AI’s transformative power when tailored to handle evolving conditions. As noted by Professor Jae-Gil Lee from KAIST’s School of Computing, overcoming the retraining dilemma is a pivotal step in scaling AI for real-world utility. This insight underscores the technology’s relevance in environments where change is constant, from patient care settings to city planning initiatives. By providing a framework that adapts seamlessly to new data patterns, TA4LS opens doors to innovative uses that could redefine operational standards in these fields. The prospect of applying such a system to varied challenges suggests a future where AI’s reach is limited only by imagination, not by technical constraints, positioning KAIST’s contribution as a catalyst for widespread technological evolution.

Reflecting on a Path Forward

Looking back, KAIST’s development of the TA4LS system marked a turning point in how industries approached AI adaptability, particularly in smart manufacturing. The strides made in enhancing defect detection accuracy and eliminating retraining needs demonstrated a clear path to more resilient operations. For manufacturers, the journey ahead involved integrating this technology to unlock sustained efficiency and cost savings. Beyond industrial applications, sectors like healthcare and infrastructure stood ready to explore how such adaptive AI could address their unique challenges. The focus shifted to fostering collaboration between researchers and industry leaders to refine and expand the use of time-series domain adaptation. Encouraging pilot programs and cross-sector partnerships emerged as vital next steps to translate academic breakthroughs into practical, scalable solutions. This momentum promised to build on past achievements, ensuring that AI continued to evolve as a dynamic, indispensable tool across diverse landscapes.