The factory floors of modern industry are undergoing a quiet yet profound transformation, moving away from the loud, repetitive clatter of rigidly programmed machinery toward a more fluid and intelligent orchestration of automated tasks. Industrial robots, long the workhorses of manufacturing, are evolving from simple mechanical arms into sophisticated partners capable of perception, adaptation, and precision on a previously unattainable scale. This evolution is being driven by the integration of advanced 3D guidance systems, a technology that equips robots with a form of sight, allowing them to navigate and interact with the three-dimensional world in a manner that mirrors human intuition. This leap in capability is not merely an incremental improvement; it represents a fundamental shift in automation, unlocking new levels of efficiency, flexibility, and intelligence that are reshaping the very nature of production, from automotive assembly lines to intricate electronics manufacturing.

Redefining Precision and Spatial Awareness

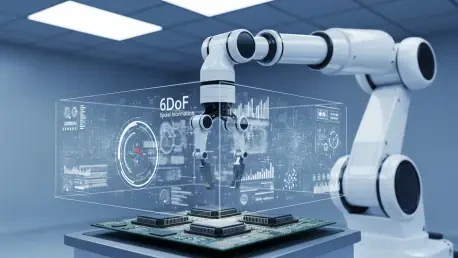

A significant breakthrough enabled by 3D guidance is the ability to track and manipulate objects with six degrees of freedom (6DoF), a capability that dramatically enhances robotic precision. This system allows a robot to perceive not only an object’s position along the X, Y, and Z axes but also its rotational orientation, commonly known as roll, pitch, and yaw. This comprehensive spatial awareness is critical in complex assembly processes, particularly within the automotive sector, where components must be aligned with exacting accuracy. With 6DoF, a robot can precisely position a car door or install a dashboard, constantly adjusting its approach in real time. It can even compensate for minute, unpredictable variables in its environment, such as thermal expansion in metal parts or subtle vibrations on the factory floor. These were previously disruptive factors that could compromise high-precision tasks, but now, this enhanced perception allows the system’s artificial intelligence to make nuanced, human-like judgments, ensuring consistent quality and reliability.

This heightened spatial intelligence directly translates into major improvements in operational efficiency and faster cycle times across a multitude of applications. Older, sensor-based robotic systems often operated in a stop-and-go fashion, pausing to take measurements before proceeding with an action, which created inherent delays and bottlenecks in the production line. In contrast, modern 3D guidance systems utilize advanced algorithms that process vast streams of spatial data instantaneously. This allows for fluid, continuous movement, eliminating the hesitations that once defined robotic work. This uninterrupted operation is particularly valuable in applications where both speed and precision are non-negotiable, such as applying sealant in a continuous bead, assembling complex engine components, or placing heavy electric vehicle battery packs. By creating a seamless workflow, 3D guidance not only accelerates production but also enhances the overall quality and consistency of the final product, pushing the boundaries of what automated systems can achieve.

Cultivating Flexibility and Data-Driven Intelligence

The adoption of 3D guidance is a key driver in the shift toward a more agile and software-defined factory environment, fundamentally changing how production lines are designed and operated. Traditionally, industrial robots were heavily reliant on expensive, custom-fabricated mechanical jigs and fixtures. These physical constraints were necessary to hold parts in exact, predetermined positions so that a pre-programmed robot could perform its task. 3D guidance systems render this hardware largely obsolete. By enabling robots to visually identify, locate, and adapt to components that are randomly positioned within their workspace, the technology liberates manufacturing from rigid physical setups. This transition reduces significant hardware overhead and fosters unprecedented agility. Instead of a time-consuming and costly physical retooling process, entire fleets of robots can now be updated, re-tasked, or re-calibrated through simple software changes, allowing manufacturers to respond rapidly to changing product designs or market demands.

Beyond the immediate operational benefits, the integration of 3D guidance has established a foundation for long-term, data-driven improvements that turn robots into appreciating assets. The high-resolution spatial data collected during every operation was not merely used for immediate action but was also archived and analyzed, serving as a powerful predictive diagnostic tool. This wealth of information allowed engineers to anticipate potential assembly failures and proactively address process inconsistencies before they led to defects. As more data was gathered over time, these predictive models became increasingly accurate, effectively allowing the robotic systems to build a “capital” of operational knowledge. This evolution has opened new pathways toward truly autonomous assembly and quality control, where robots could not only perform tasks with precision but also self-optimize their performance, fundamentally altering the manufacturing landscape and setting a new standard for intelligent automation.