In a world where aerospace technology races forward at breakneck speed, China has emerged as a trailblazer with an astonishing breakthrough that’s capturing global attention, marking a pivotal moment in aircraft manufacturing. The nation has successfully tested a fully 3D-printed turbojet engine, which isn’t merely a technical achievement but a bold statement about the future of engineering, where complex, high-performance components can be crafted with efficiency and precision previously thought impossible. Capable of generating 353 pounds of thrust and functioning at altitudes up to 13,000 feet, this engine exemplifies the transformative power of additive manufacturing. By pushing the boundaries of traditional production methods, China is not only redefining how engines are built but also challenging the status quo of the global aerospace industry. This development sparks curiosity about the broader implications for innovation, competition, and strategic autonomy in a highly competitive field. Let’s explore the layers of this remarkable advancement and what it means for the future of flight.

Engineering a New Era in Aerospace

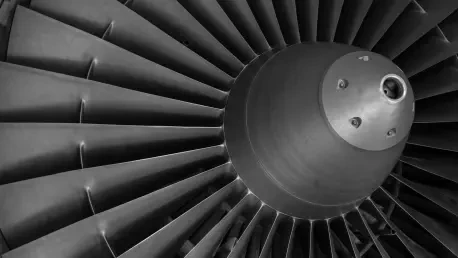

China’s latest feat in aerospace technology hinges on the revolutionary capabilities of additive manufacturing, often referred to as 3D printing. This method constructs components layer by layer, enabling the creation of intricate designs that traditional manufacturing struggles to achieve. The turbojet engine at the center of this breakthrough showcases the power of topology optimization—a design approach that maximizes structural strength while minimizing weight. This results in a lightweight yet robust engine, capable of delivering impressive performance at high altitudes. Such innovation highlights a shift away from conventional assembly techniques, opening doors to possibilities that were once considered out of reach. The ability to produce complex geometries with precision offers a glimpse into a future where aerospace components are not just functional but also optimized for efficiency in ways previously unimaginable.

Beyond the technical wizardry, this achievement signals a broader transformation in how aerospace engineering is approached. Additive manufacturing allows for rapid iteration and customization, drastically reducing the time needed to move from concept to testing. Unlike traditional methods that often require multiple parts to be sourced and assembled, 3D printing streamlines the process by creating unified structures with fewer seams and potential weak points. For China, this means not only a technological edge but also the potential to set new standards in engine design. The turbojet’s ability to operate effectively under demanding conditions proves that 3D-printed components can meet the rigorous demands of flight. As this technology matures, it could pave the way for more sustainable practices in aerospace, cutting down on material waste and energy consumption during production, thereby aligning with global pushes for greener industrial solutions.

Strategic Implications for National Autonomy

The creation of a fully 3D-printed turbojet engine carries profound strategic significance for China’s position in the global arena. By mastering this technology, the nation reduces its reliance on foreign components, a move that addresses vulnerabilities in both industrial and defense sectors. Historically, dependence on imported parts has posed risks, from supply chain disruptions to geopolitical tensions. Now, with the ability to produce high-performance engines domestically, China strengthens its industrial backbone, ensuring greater control over critical technologies. This self-sufficiency is not just about economics; it’s a matter of national security, allowing the country to safeguard its interests without external constraints. The implications of this shift resonate deeply in a world where technological independence often equates to power.

Moreover, this development positions China as a formidable player in the international aerospace market, challenging established giants who have long dominated the field. The ability to manufacture engines entirely through additive processes signals a competitive edge that could disrupt traditional hierarchies. It’s a clear message that China is not merely catching up but aiming to lead in innovation. This strategic leap also fosters domestic confidence, encouraging further investment in cutting-edge research and development. As the nation builds on this success, it may inspire a ripple effect, prompting other industries to explore similar advancements. The broader impact could reshape global perceptions of China’s technological prowess, placing it at the forefront of aerospace innovation and potentially altering the balance of influence in this critical sector over the coming years.

Redefining Manufacturing Standards

The implications of China’s 3D-printed engine extend far beyond national borders, promising to revolutionize aerospace manufacturing on a global scale. While companies like GE Aviation and Pratt & Whitney have integrated 3D-printed parts into their designs, China’s achievement of a fully printed engine sets an unprecedented benchmark. This approach slashes production timelines by eliminating the need for extensive assembly and sourcing of disparate components. Costs are reduced as well, since additive manufacturing minimizes material waste and simplifies logistics. For applications like unmanned aerial vehicles (UAVs), where lightweight and efficient designs are paramount, this technology offers transformative potential. The ability to prototype rapidly also means that new ideas can be tested and refined at a fraction of the usual time, accelerating innovation across the industry.

This shift in manufacturing paradigms could fundamentally alter how aerospace products are developed and brought to market. The flexibility of 3D printing allows for bespoke designs tailored to specific needs, whether for military, commercial, or exploratory purposes. Imagine engines customized for unique missions or aircraft with components optimized for particular environmental conditions—all achievable with less lead time than traditional methods permit. Furthermore, this technology supports scalability in ways that conventional manufacturing cannot, potentially enabling smaller firms or emerging markets to enter the aerospace space with lower barriers to entry. As China demonstrates the viability of fully printed engines, the industry may see a surge in experimentation, pushing the boundaries of what’s possible and fostering a culture of rapid, iterative progress that benefits stakeholders worldwide.

Global Competition and Collaborative Potential

China’s breakthrough sends a powerful signal to the international community, igniting both competition and curiosity across the aerospace sector. This advancement is likely to spur other nations to accelerate their own research into additive manufacturing, fearing a lag behind a rising technological leader. The result could be a global wave of innovation, as countries and companies invest heavily in similar technologies to maintain relevance. Established industry players may find their long-held dominance challenged, prompting strategic overhauls to incorporate 3D printing at scale. This competitive dynamic, while intense, has the potential to drive remarkable advancements, benefiting the field as a whole by raising the bar for performance, efficiency, and accessibility in aerospace engineering.

Yet, alongside competition lies the possibility of collaboration and shared progress. China’s success could inspire international partnerships to tackle common challenges in adopting additive manufacturing, such as developing universal standards or sharing best practices for quality assurance. The global aerospace community stands to gain from collective efforts to refine this technology, ensuring that innovations are safe, reliable, and widely applicable. Additionally, as more nations explore 3D printing, the exchange of knowledge could lead to unexpected breakthroughs, blending diverse perspectives to solve complex problems. While the immediate impact of China’s achievement is competitive, the long-term outlook might foster a more interconnected industry, where shared goals of efficiency and sustainability unite players in pursuit of a redefined future for flight.

Navigating Future Obstacles

Despite the excitement surrounding China’s 3D-printed turbojet engine, significant challenges loom on the horizon that must be addressed for this technology to reach its full potential. Scaling production to meet the demands of mass manufacturing remains a formidable task. While printing a single engine is a triumph, replicating this process consistently at an industrial level requires infrastructure, expertise, and resources that are still in development. Quality control is another critical concern, as even minor defects in printed components can compromise safety and performance in the high-stakes environment of aerospace. Ensuring that every engine meets stringent standards will demand rigorous testing and refinement of the additive manufacturing process, a journey that could span years before widespread adoption is feasible.

Additionally, navigating the complex landscape of certification poses a hurdle not just for China but for any nation pursuing this path. Aerospace regulations are notoriously strict, designed to prioritize safety above all else, and integrating 3D-printed engines into commercial or military fleets will require extensive validation to gain regulatory approval. These standards vary across regions, adding layers of complexity to global implementation. Overcoming these obstacles will necessitate collaboration between engineers, policymakers, and industry leaders to establish frameworks that balance innovation with reliability. As efforts continue, the focus must remain on incremental progress, building trust in this technology through transparent testing and data-driven improvements. Only then can the promise of 3D-printed engines transition from groundbreaking prototype to everyday reality in the skies.