The advent of automation has ushered in a transformative era in manufacturing across a spectrum of sectors, including automotive and pharmaceuticals. As sophisticated machinery replaces human labor, the face of production is being dramatically altered. This shift has catalyzed unprecedented advancements in the speed, efficiency, and cost-effectiveness of producing goods. The implications of this transformation are manifold; productivity has surged, precision has been elevated, and economies of scale have been realized. Consequently, this has not only heightened profitability for businesses but also redefined the skill sets required from the workforce. The repercussions extend beyond the factory floor, influencing supply chains, market dynamics, and consumer behaviors. Automation’s integration into production is a hallmark of modern industrial evolution, signifying a milestone in how humans harness technology to amplify their capabilities and economic output.

A Deep Dive into Automated Industries

Automotive Advancements

In the auto industry, the integration of automation has revolutionized the production line. Precision robots carry out tasks such as welding, painting, and assembly with exceptional uniformity. This boosts the speed and enhances the quality of vehicle manufacturing. Automation delivers particularly noticeable improvements in welding, where every joint is welded with consistent precision, reducing the inconsistencies associated with human labor. Consequently, these advancements allow car manufacturers to produce vehicles with heightened safety and reliability. Automation’s role in efficient production not only increases output but also ensures each vehicle meets high-quality standards in an industry where precision is critical for both performance and consumer safety. When errors are minimized, recalls are also reduced, saving manufacturers from costly fixes and protecting brand reputation. This focus on automation has shifted the automotive landscape, creating cars that are the finest in their class.

Precision in Electronics

Manufacturing automation has revolutionized the electronics sector, where precision is paramount. Automated tools have been pivotal for advancements in miniaturization and the complex construction of electronic devices. One standout example is the Surface-mount technology (SMT) machinery, which can accurately place numerous minuscule parts onto circuit boards, achieving a level of precision that human hands cannot. This meticulous precision is critical for the functionality and durability of electronic products. As a result, consumer gadgets such as smartphones and computers are produced to meet exceedingly stringent quality expectations. Automation in electronics manufacturing not only enhances efficiency and consistency but also pushes the boundaries of what is possible in electronic design and complexity. This technology allows for the acceleration of innovation in the industry, underscoring the contribution of automation to the proliferation of high-quality electronic goods in the modern market.

The Future of Automated Manufacturing

Sustainability and Efficiency

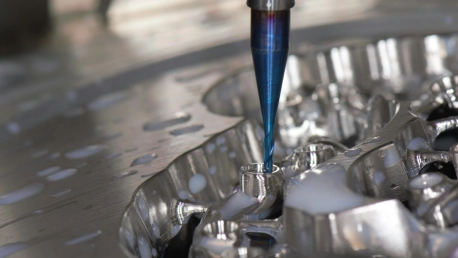

Manufacturing automation not only streamlines production but significantly enhances sustainability. Systems are precisely engineered for material and energy efficiency, which diminishes waste and the environmental impact of manufacturing. Automated tools like precision cutting machines maximize raw material usage, slashing unnecessary waste and saving on costs. Furthermore, automated operations often require less energy than their manual counterparts because they can be adjusted for optimal speed and power settings. This precision ensures a balance between productivity and eco-conscious manufacturing, leading to a smaller carbon footprint. In this way, automation supports a more sustainable production lifecycle, contributing to greener industry practices. The advantages of such systems extend not just to cost savings but also to the broader goal of responsible resource management, supporting a more sustainable future.

Human Roles in an Automated Era

As automation advances, concerns of widespread joblessness are met with the notion that it can liberate humans for more fulfilling roles. Machines relieve us from monotonous, strenuous tasks, allowing focus on inventive, strategic, or managerial duties. This shift may call for re-education and acquiring new skills, which could elevate the overall workforce competency. Automation not only steers workers towards engaging in higher-level functions, but it also enhances workplace safety. By reassigning hazardous tasks to machines, we can reduce occupational injuries and health risks. The evolution towards automation isn’t just about efficiency; it represents an opportunity to reshape work into something safer and more intellectually rewarding. This perspective suggests a future where automation isn’t a threat, but a catalyst for improvement in both the nature and quality of work.