In the rapidly evolving landscape of manufacturing, companies are constantly seeking innovative solutions to remain competitive and efficient. Speedpart, a seasoned player in the toolmaking industry, is at the forefront of this transformation with its cutting-edge use of 3D printing technology. By showcasing groundbreaking capabilities at the Moulding Expo in Stuttgart, Speedpart has demonstrated how integrating 3D printing with traditional manufacturing methods can revolutionize the way complex components and tools are created. This innovative approach not only shortens production timelines but also offers unparalleled flexibility in design, ultimately enhancing both operational efficiency and product quality. The company’s hybrid strategy is a game-changer in the realm of toolmaking, offering a glimpse into the future of manufacturing.

Integration of Traditional and Additive Manufacturing Techniques

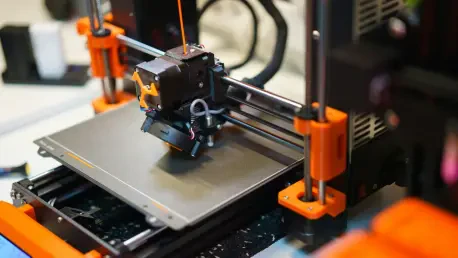

Speedpart merges the benefits of additive manufacturing with traditional methods like CNC machining and injection molding. By embracing advancements in 3D printing for metals and plastics, Speedpart slashes toolmaking time, reducing production timelines considerably. This approach facilitates the manufacture of complex components that traditional methods would find too time-consuming. Additive manufacturing’s flexibility is a notable perk, allowing for the construction of detailed structures such as cooling channels that conform to contours. These channels boost the efficiency and lifespan of injection molding tools by curtailing cycle times, thus enhancing production speed and effectiveness.

In its commitment to sustainability, Speedpart employs resource-saving methods that minimize waste, demonstrating a dedication to reducing environmental harm. Strategic material usage plays a vital role in this eco-friendly mission, cutting costs while conserving resources. By tackling waste and efficiency, Speedpart is ushering in a new era for sustainable toolmaking. As the sector evolves, Speedpart’s fusion of cutting-edge tech and eco-conscious practices is set to reshape manufacturing, bridging traditional and modern methods for future success.