The dawn of the industrial revolution brought forth machines that transformed the nature of work. In today’s era, yet another revolution is underway, this time led by industrial robotics. Boasting increased productivity, unmatched precision, and heightened safety, robotics is reshaping the once familiar landscapes of the manufacturing sectors. This transformative wave is amplified by pressures such as rising labor costs, uncompromising quality expectations, and the ceaseless quest for operational excellence. As industries grapple with global competition and technological change, the embrace of automated solutions has become not just advantageous, but essential for survival.

The Growth and Valuation of Industrial Robotics

At the frontier of innovation, the industrial robotics market is thriving, with a current estimated worth of USD 25.45 billion. Its trajectory points skyward, predicted to reach a staggering USD 59.93 billion by 2030. This upswing is shaped not just by increases in demand but by the sophistication and capabilities of the robots themselves. The market’s compound annual growth rate (CAGR) of 11.3% from 2023 to 2030 narrates a tale of burgeoning reliance on robotic systems across all manufacturing horizons. With this steady growth, the role of industrial robotics in the global economy is set to become more pivotal, laying the groundwork for the next generation of industrial advancements.Businesses beholden to efficiency and quality standards are turning to robotics not just as tools, but as integral components of their operational strategy. This shift signifies not only an increased output but a transformation in the very approach to how goods are manufactured and how workers interact with machines. By integrating advanced robotics into their production lines, manufacturers are now poised to charter new territories in efficiency, flexibility, and customization, crafting a narrative of progress grounded in technology.

Types and Applications of Industrial Robots

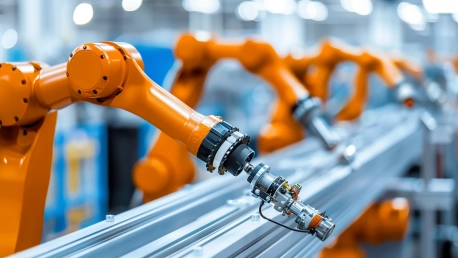

From the nuanced task of assembling delicate electronics to the high-octane environment of automotive production floors, industrial robots are the linchpins of modern manufacturing. Classified into several types, such as articulated, SCARA, delta, Cartesian, and collaborative robots, each brings unique capabilities to the table. Their applications are as diverse as the industries they serve, a testament to the versatility inherent in today’s robotics technology.Collaborative robots or ‘cobots’, for instance, stand out for their ability to work alongside human colleagues, bringing flexibility to tasks previously deemed incompatible with automation. Whether it’s the precision of an articulated robot arm in a welding operation or the speed of a delta robot in packaging, the spectrum of tasks now assumed by these mechanical marvels is only expanding. As such, the role of robots transcends functional applications, evolving into a strategic element that defines competitive edges and innovation trajectories for industries worldwide.

Automation: The Driving Force in Automotive and Electronics Sectors

Driving much of the robotic market’s expansion are the automotive and electronics sectors, industries where precision and repeatability are not simply desired but required. Robots have become indispensable in these sectors, entrusted with tasks such as assembling intricate circuit boards or welding chassis components – responsibilities that demand exactitude. The integration of robotics has resulted in monumental leaps in production efficiency and product quality, setting new benchmarks across the manufacturing landscape.The relentless demand for consumer electronics and the continual evolution of vehicle technology have cemented automation as a cornerstone of these industries. It ensures not only consistency and safety for workers but also maintains the pace necessary to keep up with consumer demands. As companies strive to innovate and meet ever-tightening regulatory standards, industrial robotics emerges as a key ally, reinforcing the foundations of these critical market sectors.

Geographical Market Trends in Robotics

Diving into the geographical distribution of robotics, the Asia-Pacific region emerges as a dominant force, propelled by aggressive industrialization and automation initiatives. This vibrant activity is echoed in North America and Europe, regions that are similarly embracing the robotics movement to fortify their manufacturing bases. This geographical spread is symptomatic of a broader industrial paradigm shift that deems industrial robotics not merely a tool but a strategic imperative to sustain and grow manufacturing prowess.The push for Industry 4.0 and smart factories is providing additional thrust, as companies across the globe align their operations with the principles of digitalization and interconnectedness. Asia-Pacific’s stake in the market suggests a clear vision towards embracing these principles, while North America and Europe’s technological maturity positions them as innovation leaders, further fueling robotic advancements within their respective borders.

The Major Players Shaping the Market

The arena of industrial robotics is not just dynamic but highly competitive, with major players like ABB, FANUC, YASKAWA, and KUKA leading the charge. These giants not only contribute to the technological thresholds of robotics but also shape the strategic landscape by pushing the envelope of what’s possible. Their commitment to innovation ensures a steady cadence of advancements, which, in turn, propels the entire sector forward.These companies are at the forefront, redefining the capabilities of robotics systems. Their quest is not just to create robots that lift or shift but to engineer systems that reason, learn, and collaborate. As they vie for market leadership, their strategies and technological breakthroughs become pivotal narratives in the story of industrial robotics—a tale of relentless improvement and visionary foresight.

The Technological Evolution in Robotics

Technological progress is the axis around which the future of industrial robotics spins. The market is witnessing an evolution toward robots that are not only collaborative but also imbued with artificial intelligence (AI) and linked to cloud-based monitoring systems. This technological renaissance is transforming robots into partners capable of learning and adapting to complex environments and tasks.With the fusion of AI, the traditional boundaries of robotics are dismantled, enabling a new breed of smart machines. These AI-enhanced robots promise to bring heightened levels of adaptability to the production line, heralding an era where machines are not just tools but intelligent agents capable of contributing to decision-making processes. The integration of cloud technology further amplifies this transformation, ushering in an age of robotics that is as connected and data-driven as the companies they serve.

Overcoming Challenges in the Robotics Sector

Despite its trajectory and promises, the path to robotics dominance is strewn with challenges. The economic hurdles, such as the steep initial costs of robotic systems, the complex choreography of integrating them into existing production lines, and the persistent concern of job displacement, cannot be overlooked. Moreover, the shortage of skilled technicians to maintain and program these sophisticated machines adds a layer of complexity to the adoption of robotics.Nevertheless, these challenges do not dampen the sector’s potential; they instead beckon for innovative solutions. Robotics companies and manufacturing firms alike recognize the need to develop more cost-effective, user-friendly, and flexible robotic systems. Training programs and educational initiatives are part of the solution, equipping a new workforce with the skills to operate and coexist with robots. As the market tackles these obstacles, the horizon glimpses a future of collaborative problem-solving between humans and robots.

AI and Machine Learning: Revolutionizing Robot Adaptability

AI and machine learning are more than mere buzzwords in the industrial robotics space; they are the cornerstone of a new frontier in robot adaptability. As these technologies mature, robots are learning to navigate unpredictable environments and perform tasks that were once thought to be beyond the scope of automation. This includes sophisticated decision-making and problem-solving abilities that enable them to tackle unforeseen challenges.The intrinsic learning capabilities provided by machine learning algorithms mean that robots can not only perform pre-programmed tasks but also adapt to new scenarios, contributing to the evolution of Industry 4.0. It is this adaptability that underlines AI’s transformative impact on robotics, empowering machines with the intelligence to become game-changers in a wide array of manufacturing contexts.

The Emergence of Service Robotics and New Markets

Industrial robotics is sparking a revolution akin to that of the industrial revolution, unleashing productivity, precision, and safety in manufacturing. Driven by labor costs, quality demands, and operational excellence, the transformation shapes not just the market, but the necessity for businesses to survive and thrive amidst global competition and technological advancements. Automation has transitioned from advantageous to essential, with robotics being central to future success in a rapidly evolving market landscape.