The advent of 3D printed metal stands at the vanguard of a transformative wave set to redefine the industrial landscape. By 2028, we anticipate witnessing a significant reshaping of how key sectors operate, spurred by advancements in additive manufacturing. This article delves into the potential metamorphosis of these sectors through the lens of emerging 3D metal printing technologies.

The Advent of 3D Printed Metal Technology

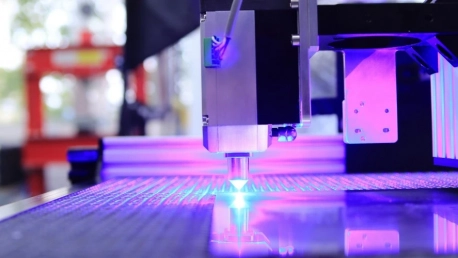

A Paradigm Shift in Manufacturing

The manufacturing world is bracing for a paradigm shift with the advent of 3D printed metal. Complex parts, once hindered by the constraints of traditional manufacturing methods, are now within reach. The technology heralds a new era where intricate designs, once deemed too complex or uneconomical to produce, are becoming standard fare. As industries adapt, the ripple effect is evident in reduced lead times, minimized waste, and the unfettering of designers’ creative limitations.

Key Players and Technological Pioneers

The relentless march of 3D printed metal owes much to the technological pioneers shaping its course. Companies like 3D Systems Corporation and Stratasys Ltd. are at the forefront, driving innovation through rigorous research and development. These key players have not only mastered the technology but are also setting industry standards, pushing the boundaries of what can be achieved with metal additive manufacturing.

Impact on Specific Industries

Aerospace & Defense: Pursuing the Sky

Nowhere is the potential of 3D printed metal more evident than in the aerospace and defense sector. Here, the technology promises leaps in efficiency and functionality. The ability to fabricate lightweight, structurally sound components is revolutionizing aircraft and spacecraft design. The sector is increasingly turning to 3D printed metal for both prototyping and end-use parts, capitalizing on its strengths to reach new heights in design and innovation.

The Automotive Revolution

In the automotive industry, 3D printed metal is not just a novel innovation—it’s set to be a cornerstone of the next industrial revolution. Manufacturers are exploring new realms in vehicle design, harnessing the capability to produce parts that combine strength with significant weight reductions. The consequent impact on fuel efficiency and performance is charting a course toward a more sustainable and dynamic future for the industry.

The Medical Field: Precision and Customization

In the medical and dental worlds, precision and customization are paramount. 3D printed metal stands as a beacon of innovation, enabling the production of patient-specific implants and surgical instruments. This technology is not just enhancing patient outcomes but is also revolutionizing the very nature of medical treatment procedures. As doctors and surgeons push for more personalized care, 3D printed metal is proving to be an indispensable ally.

Market Dynamics and Challenges

Drivers of Market Growth

The engines driving the 3D printed metal market are as varied as they are powerful. The fervent demand from industries such as aerospace, automotive, and medical propels the market forward. Investments in R&D are securing the technological advancements necessary to sustain growth, while consumer trends toward customization continue to create new market opportunities.

Hurdles on the Path to Innovation

Despite its promising future, 3D printed metal technology confronts significant challenges. The process remains energy-intensive, and the fine precision work requires a significant investment in skilled labor. The rigorous material standards needed for high-quality output further complicate the production process, introducing a barrier to rapid scaling and adoption.

Regional Market Insights

North America: An Innovation Hub

North America has emerged as a crucible of innovation in the 3D printed metal market. The region’s market dominance is sustained by robust industries and favorable regulatory environments that underpin research efforts and technology deployment. Home to some of the leading names in the industry, it is a key player in the global narrative of additive manufacturing.

Asia-Pacific: The Emerging Frontier

The Asia-Pacific region is rapidly becoming a force to be reckoned with in the 3D printed metal domain. With economies investing in technology and infrastructure, the region is poised to harness the transformative power of 3D printing. The diverse manufacturing base and the drive for technological adoption suggest a vibrant future for Asia-Pacific in the global 3D printed metal landscape.

Looking Ahead: Strategic Market Developments

Sales and Distribution: Navigating the Market

To fully realize the potential of the 3D printed metal market, companies are rethinking their sales and distribution paradigms. The strategic positioning of sales channels, coupled with savvy marketing tactics, will determine the traction and penetration of 3D printing technologies. Understanding these strategies is key to forecasting market behavior and anticipating shifts in industry dynamics.

Competitive Landscape and Future Innovations

The rise of 3D printed metal is poised to revolutionize the way industries function by 2028. This cutting-edge form of additive manufacturing brings with it a host of benefits, such as the ability to produce complex parts with fewer materials, reduced waste, and increased speed to market for new products. As we look toward a future where this technology becomes more mainstream, it promises to reshape sectors like aerospace, automotive, and healthcare. Companies are already exploring the possibilities, from printing aircraft components to custom medical implants, pushing the boundaries of innovation. The impact on supply chains and manufacturing processes will be profound, potentially leading to more localized and personalized production. This shift could herald a new era of efficiency and customization, transforming traditional industrial practices and enhancing global competitiveness. As we approach this exciting juncture, the industry stands on the cusp of a major technological leap that will redefine manufacturing as we know it.