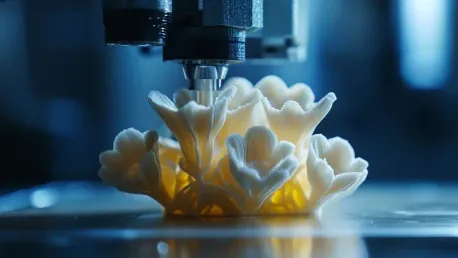

Stratasys has taken a significant leap forward in the realm of 3D printing technology with the unveiling of its TechStyle Fabric Alignment Station, a move set to revolutionize the fashion industry. Building upon the foundation laid by the J850 TechStyle full-color textile 3D printer, this innovative technology addresses intricate challenges that designers face when integrating 3D-printed designs with traditional 2D printed textiles. By automating the alignment process of 2D patterns with 3D designs on specific textile areas such as pockets and patches, Stratasys aims to offer unparalleled precision and efficiency, making it an essential tool for high-end designers.

Enhancing Production Accuracy and Efficiency

Streamlining Precision in Garment Production

The TechStyle Fabric Alignment Station stands as a beacon for improving production accuracy and efficiency within the fashion industry. In traditional garment making, the integration of 3D designs onto textile surfaces often involves a labor-intensive process rife with trial and error, ultimately consuming time and elevating costs. This new technology mitigates these challenges by automating the meticulous alignment process, thereby enhancing accuracy and significantly reducing the time required for production. As a result, designers can now focus more on creativity and less on correcting mistakes, paving the way for innovative fashion designs to reach the market faster than ever before.

This precision not only benefits high-end designers but also cascades down to the mass production of garments. With the TechStyle Fabric Alignment Station, manufacturers can ensure that every piece is produced with the same level of detail and care, maintaining consistent quality across the board. This development is particularly important as the fashion industry grapples with fast fashion demands, where speed and accuracy are paramount. By seamlessly merging 3D designs with 2D textiles, Stratasys provides a solution that blends creativity with operational efficiency, addressing both ends of the fashion spectrum.

Responding to Consumer Demand for Customization

The fashion industry has seen a burgeoning demand for personalized and bespoke fashion items, trends that show no signs of abating. Consumers today are keen on expressing their individuality through unique clothing items, a demand that the TechStyle Fabric Alignment Station vigorously addresses. By enabling designers to place 3D designs accurately on predefined textile areas, the technology offers greater flexibility in customization. Designers can experiment with various textures, colors, and patterns, crafting one-of-a-kind pieces that cater to niche markets or specific consumer preferences.

This level of customization extends beyond just aesthetic appeal. Functional features such as enhanced durability, weather resistance, and tailoring of garments for specific activities or environments become easier to integrate. For instance, sportswear can be customized for better performance, while casual wear can be designed to offer more comfort or aesthetic allure. The ability to produce such tailored items efficiently aligns with the growing consumer inclination toward personalized products. Overall, this gives designers the tools they need to stay ahead in a competitive market, continuously innovating their offerings based on real-time consumer feedback and trends.

Fostering Sustainability in Fashion

Reducing Material Waste

A significant selling point of the TechStyle Fabric Alignment Station is its contribution to sustainability, a growing priority in today’s fashion landscape. Traditional garment production methods often result in considerable material waste, an issue that brands and consumers alike are increasingly focusing on. By enabling precise alignment and integration of 3D designs on textiles, this technology minimizes the misalignment and errors that typically lead to material wastage. The automation and accuracy delivered by the TechStyle Fabric Alignment Station translate to optimized use of resources, which consequently reduces waste.

The sustainability aspect of Stratasys’ technology finds further validation from the company’s earlier “direct to garment” technology. In a study commissioned by the Additive Manufacturer Green Trade Association (AMGTA), the shift from traditional manufacturing to additive manufacturing (AM) was shown to reduce CO2e emissions by 24.8% for the production of 16,000 units of a logo appliqué for luxury designer shoes. Such data provide concrete evidence of the environmental benefits of adopting Stratasys’ latest innovation, reinforcing its role in steering the fashion industry towards more sustainable practices.

Aligning with Industry Trends

The global fashion industry is experiencing a paradigm shift as it increasingly adopts advanced technologies like 3D printing to meet emerging demands for customization and sustainability. Stratasys’ TechStyle Fabric Alignment Station represents the convergence of these trends, offering a sophisticated tool that supports both personalized design and environmentally conscious production. The technology is poised to transform how designers approach the creative process, providing them with the means to achieve extreme precision without compromising on the eco-friendly aspects of production.

Industry experts concur that such technological integration is becoming indispensable in fashion, not just for improving operational efficiency but for meeting the expectations of a conscientious consumer base. Brands that harness the potential of the TechStyle Fabric Alignment Station stand to gain a competitive edge, both in terms of innovating their product lines and demonstrating a commitment to sustainability. By merging cutting-edge technology with growing environmental awareness, Stratasys is setting a new standard in fashion design and production, making a compelling case for the broader adoption of such advanced solutions.

Conclusion

Stratasys has made a significant advancement in 3D printing technology with the launch of its TechStyle Fabric Alignment Station, poised to transform the fashion industry. This groundbreaking technology builds on the capabilities of the J850 TechStyle full-color textile 3D printer, tackling the complex issues designers encounter when merging 3D-printed elements with traditional 2D printed textiles. The TechStyle Fabric Alignment Station automates aligning 2D patterns with 3D designs on specific textile areas such as pockets and patches, offering unmatched precision and efficiency. This innovation aims to equip high-end designers with an indispensable tool for creating intricate and unique designs that seamlessly integrate 3D-printed elements with conventional fabrics. By automating what was once a tedious and error-prone process, Stratasys opens up new creative possibilities and sets a new standard for the fashion industry, making it easier for designers to experiment and innovate. This move underscores Stratasys’s commitment to pushing the boundaries of technology in the fashion world.