In a world increasingly burdened by plastic waste and the urgent need for sustainable manufacturing solutions, a Western Australia-based startup is making waves with a revolutionary approach to industrial production. Hyperion Systems, founded by 27-year-old robotics engineer Josh Wigley, has emerged as a beacon of innovation by developing a cutting-edge 3D printing platform known as the ‘Factory-in-a-Box.’ This technology not only promises to redefine large-scale manufacturing but also tackles environmental challenges head-on by utilizing recycled materials. With a recent $385,000 matched-funding grant from the Australian Government’s Innovation Growth Program, the company is poised to scale its operations and bring transformative change to multiple industries. This remarkable journey from a visionary idea to a game-changing solution highlights the potential for technology to address both economic and ecological demands in a rapidly evolving global landscape.

Revolutionizing Manufacturing with Innovative Technology

Unveiling the Factory-in-a-Box Platform

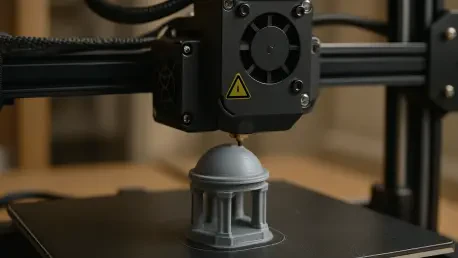

At the heart of Hyperion Systems’ breakthrough is its modular and transportable industrial 3D printing system, meticulously designed and assembled in Western Australia. This platform integrates custom hardware, proprietary software, and pellet-based plastic feedstock—both new and recycled—to form a complete manufacturing setup. Utilizing Large Format Additive Manufacturing (LFAM) combined with Fused Granular Fabrication (FGF), it can produce massive components up to 10 meters in length, ranging from boat hulls to architectural sculptures. A distinguishing feature lies in its ability to incorporate machining capabilities within the same setup, allowing parts to be printed and finished without additional steps. This innovation slashes production times dramatically, as seen in the creation of boat-building molds that once took six months but now take just three days, while also minimizing waste and reducing costs for industries seeking efficient solutions.

Transforming Production Timelines and Efficiency

The impact of Hyperion’s technology on production timelines cannot be overstated, as it offers a paradigm shift for industries accustomed to lengthy and resource-intensive processes. By streamlining the creation of large-scale items, such as concrete formwork or furniture, the system empowers businesses to meet tight deadlines without compromising on quality. The efficiency gains are complemented by significant cost reductions, making advanced manufacturing accessible to a broader range of companies. Beyond speed, the platform’s design as a mobile unit means it can be deployed directly to a client’s site, eliminating logistical hurdles associated with transporting oversized components. This adaptability positions Hyperion as a leader in addressing modern manufacturing challenges, providing a glimpse into a future where production is not only faster but also more aligned with the dynamic needs of diverse sectors like marine, construction, and defense.

Driving Sustainability and Industry Impact

Championing a Circular Economy with Recycled Materials

A cornerstone of Hyperion Systems’ mission is its unwavering commitment to sustainability through the use of recycled plastics in its manufacturing process. The platform is engineered to process thermoplastic pellets sourced from waste streams, including everyday items like PET bottles and even decommissioned subsea infrastructure. By converting this plastic waste into high-value products, the company aligns with global calls for environmentally responsible production practices. This circular approach not only reduces the burden on landfills but also offers industries a viable alternative to traditional materials, proving that sustainability and profitability can coexist. Josh Wigley’s original vision of transforming waste into large, functional items like boats has evolved into a scalable solution that addresses pressing ecological concerns while meeting industrial demands with precision and innovation.

Remarkable Achievements and Future Growth

Hyperion Systems has achieved extraordinary milestones in a short span, underscoring its potential to reshape manufacturing landscapes across Australia and beyond. Notable accomplishments include 3D printing the country’s first boat hull—a 3-meter vessel completed in just 36 hours—and constructing the largest 3D-printed structure at Kalgoorlie TAFE as a public artwork. The company has also made strides in education by installing a robotic printing system at Griffith University for design students, while expanding its reach into sectors like oil and gas and defense. With a move to a larger facility in Henderson to support marine and subsea businesses at the Australian Marine Complex, and backed by Perth businessman David Budge as a founding investor and Chief Technology Officer, Hyperion is well-positioned for growth. The federal grant will further enable the rollout of a Manufacturing-as-a-Service (MaaS) model, allowing businesses worldwide to lease the mobile system and access high-quality production without prohibitive upfront costs.

Shaping a Sustainable Manufacturing Legacy

Reflecting on the strides made by Hyperion Systems, it’s evident that the company has carved a path toward a more sustainable and efficient industrial future. The integration of recycled materials into large-scale production marked a turning point for industries seeking greener alternatives. Collaborations across marine, construction, and education sectors demonstrated the versatility and impact of the technology, while strategic investments and government support fueled expansion. Looking ahead, businesses and policymakers can draw inspiration from this model by prioritizing innovations that balance economic growth with environmental stewardship. Exploring partnerships with similar innovators or investing in scalable, eco-friendly technologies could amplify the reach of such solutions. As industries continue to evolve, adopting accessible and sustainable manufacturing practices like those pioneered by Hyperion will be crucial in addressing global challenges and building a resilient production ecosystem for generations to come.