Plastic waste has become a pressing environmental challenge, with millions of metric tons generated annually. The complexity of recycling diverse plastic materials often leads to ineffective waste management, exacerbating pollution problems. However, a groundbreaking project in Germany, a collaboration between the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) and Hochschule Bremen – City University of Applied Sciences (HSB), aims to revolutionize how plastic waste is repurposed. By utilizing additive manufacturing, specifically 3D printing, these researchers are transforming household plastic packaging waste into valuable products, setting an inspiring precedent for waste recycling.

Harnessing Additive Manufacturing for Recycling

The Growing Challenge of Plastic Waste

Germany produces a staggering 5.6 million metric tons of plastic packaging waste each year, most of which is notoriously difficult to recycle. The heterogeneity and contamination of post-consumer plastic waste present significant obstacles to recycling efforts. Standard recycling methods often fall short due to the mixed nature of the waste and the presence of impurities.

These challenges are compounded by stringent regulatory requirements, such as the EU Packaging and Packaging Waste Regulation (PPWR). This regulation mandates that by 2030, packaging must contain 10 to 35 percent recycled materials, depending on the type of plastic. Consequently, there is an escalating need for innovative recycling methods that can produce high-quality recycled polymers suitable for such applications.

Advanced Techniques for High-Purity Recycled Plastic

The collaboration between Fraunhofer IFAM and HSB has led to promising advancements in purifying recycled plastic. The process begins with grinding the plastic waste into smaller particles, followed by thorough washing and removal of contaminants. This multi-step purification process ensures that the recycled plastic achieves a purity level exceeding 99.8 percent.

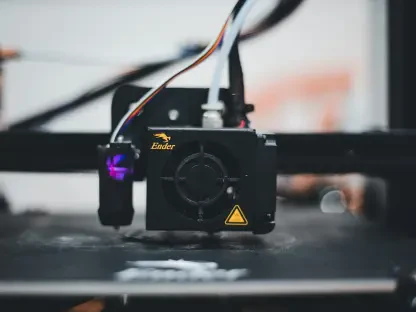

Once the waste is sufficiently purified, Fraunhofer IFAM utilizes advanced processing techniques to convert the material into a homogeneous polypropylene strand. This stage of the process is critical for creating a consistent and reliable feedstock suitable for 3D printing. The result is a high-quality recycled plastic that can meet the rigorous demands of additive manufacturing.

From Waste to Valuable Products

3D Printing with Recycled Plastic

Employing 3D printing technology, researchers have successfully demonstrated that post-consumer plastic waste can be transformed into valuable products. One notable example is the production of caps from recycled polypropylene. This achievement is a testament to the potential of additive manufacturing to create practical and marketable items from materials that would otherwise contribute to environmental degradation.

The versatility of 3D printing allows for considerable flexibility in the kinds of products that can be manufactured. Beyond simple items like caps, there is the potential to create more complex components, which can be tailored to specific industry needs. The ability to rapidly prototype and produce customized parts adds a significant dimension to the value proposition of using recycled plastics in additive manufacturing.

Enhancing the Material Properties

Researchers are also exploring ways to enhance the properties of recycled plastics to expand their applicability further. One approach involves incorporating additives, such as glass fibers, into the recycled polypropylene. These additives can significantly improve the material’s strength and durability, making it suitable for more demanding applications.

Potential uses for these enhanced materials include components for the aviation and automotive industries, where high-performance materials are critical. By optimizing the recycled plastic with the right additives, it becomes possible to meet the stringent requirements of these industries, opening up new avenues for the use of recycled materials. This ongoing research underscores the potential of additive manufacturing to revolutionize the recycling of plastics and create high-value products from waste.

Meeting Future Regulatory Requirements

Achieving High-Quality Standards

As the EU Packaging and Packaging Waste Regulation (PPWR) pushes for higher percentages of recycled materials in packaging, achieving high-quality standards in recycled plastics becomes increasingly crucial. The methodologies developed by Fraunhofer IFAM and HSB not only aim to meet current regulations but also anticipate future requirements. By refining the recycling process to produce high-purity polypropylene suitable for 3D printing, these researchers are setting a benchmark for quality in recycled materials.

This focus on quality is essential for ensuring that recycled plastics can compete with virgin materials in terms of performance and reliability. By committing to rigorous standards, the project aims to demonstrate that recycled plastics can be a viable alternative for various applications, thereby encouraging wider adoption of recycled materials in the industry.

Legislative and Market Implications

The implications of this research extend beyond technological innovation to legislative and market dynamics. Stricter regulations mandating the use of recycled materials present both a challenge and an opportunity for the plastics industry. Companies that can integrate high-quality recycled plastics into their manufacturing processes will be well-positioned to comply with regulatory requirements and capitalize on the growing market for sustainable products.

Moreover, the success of this project could inspire similar initiatives globally, promoting a more circular economy where waste is systematically repurposed into valuable resources. The combination of legislative pressure and technological advancements in recycling processes can drive significant changes in how plastic waste is managed and utilized.

Future Prospects and Broad Applications

Expanding the Scope of Recycled Plastics

The ongoing advancements in recycling technology and additive manufacturing indicate that the scope of applications for recycled plastics will likely expand. As researchers continue to refine processes and develop new additives, the potential use cases for recycled materials will grow. Industries such as construction, consumer electronics, and medical devices may also benefit from high-quality recycled plastics.

Furthermore, the increasing awareness and demand for sustainable products among consumers will drive the adoption of recycled materials. As more companies integrate recycled plastics into their products, the market for such materials will continue to grow, creating a positive feedback loop that encourages further innovation and investment in recycling technologies.

Collaboration and Innovation

The collaboration between Fraunhofer IFAM and HSB highlights the importance of interdisciplinary and inter-institutional cooperation in addressing complex environmental challenges. By combining expertise in materials science, engineering, and environmental science, these institutions have demonstrated the potential for innovative solutions to one of the most pressing issues of our time.

Future progress will likely depend on continued collaboration between academia, industry, and policymakers. By working together, these stakeholders can develop and implement strategies that promote the sustainable use of plastics, reduce waste, and minimize environmental impact. This project serves as a model for how collaborative efforts can lead to meaningful advancements in technology and sustainability.

Conclusion

Plastic waste has become an urgent environmental issue, with millions of metric tons produced yearly. The complexity in recycling various plastic materials often results in inefficient waste management, further aggravating pollution problems. However, a pioneering project in Germany aims to change how plastic waste is reused. This collaboration between the Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM) and Hochschule Bremen – City University of Applied Sciences (HSB) is groundbreaking. They’re employing additive manufacturing, specifically 3D printing, to repurpose household plastic packaging waste into useful products. This innovative approach not only improves recycling efficiency but also turns waste into valuable items, setting a noteworthy example for plastic waste management and recycling worldwide. By transforming everyday plastic waste into practical products, these researchers are paving the way for sustainable practices and offering a hopeful perspective on addressing plastic pollution.