The manufacturing sector is experiencing a profound transformation, propelled by the Internet of Things (IoT), which is revolutionizing how factories operate through interconnected devices, advanced data analytics, and seamless automation. Valued at an impressive USD 348.9 billion currently, this market is on track to reach a staggering USD 1,375.1 billion by 2035, driven by a robust compound annual growth rate (CAGR) of 14.7%. This remarkable growth signals a new era for industrial operations, where smart factories are becoming the norm rather than the exception. The integration of IoT is not merely a technological upgrade but a fundamental shift addressing critical challenges like operational downtime, resource waste, and escalating costs. By enabling real-time monitoring and predictive insights, IoT empowers manufacturers to make data-driven decisions that enhance efficiency and competitiveness. As this technology continues to reshape the industry, understanding its drivers and implications becomes essential for stakeholders aiming to stay ahead in a rapidly evolving landscape.

Revolutionizing Operations with Smart Factories

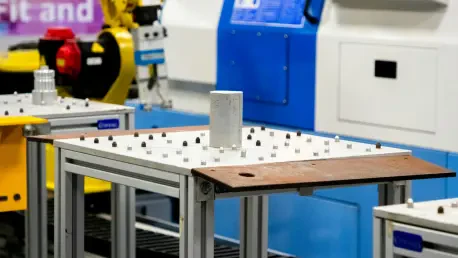

The concept of Industry 4.0 has ushered in a new wave of innovation, with smart factories at the forefront of integrating IoT to redefine manufacturing processes. These advanced facilities leverage a network of connected devices to monitor production in real time, ensuring every element operates at peak performance. The ability to track machinery and systems continuously allows for immediate adjustments, minimizing inefficiencies and preventing small issues from becoming major disruptions. A key feature of this transformation is predictive maintenance, where IoT sensors detect potential failures before they occur, significantly reducing downtime and repair costs. This proactive approach not only boosts productivity but also extends the lifespan of critical equipment, offering a substantial return on investment for manufacturers willing to embrace digital connectivity as a core component of their operational strategy.

Smart factories go beyond mere monitoring, pushing the boundaries of what’s possible with deep automation and sophisticated data analytics. By connecting IoT systems with cutting-edge tools, these environments create a seamless flow of information that drives smarter decision-making across the production cycle. For instance, real-time data can optimize workflows by identifying bottlenecks and reallocating resources instantly, ensuring smooth operations even under high demand. Additionally, the focus on automation reduces human error, allowing for precision that manual processes often lack. This level of control transforms traditional factories into dynamic hubs of innovation, capable of adapting to market changes with agility. As more companies adopt this model, the competitive landscape shifts, rewarding those who prioritize technological integration with enhanced output and cost savings that set them apart in an increasingly crowded marketplace.

Enhancing Capabilities through Technology Integration

IoT’s impact on manufacturing is amplified through its synergy with complementary technologies like artificial intelligence (AI), edge analytics, and cloud computing, which together elevate operational capabilities to unprecedented levels. AI processes vast amounts of data generated by IoT devices to uncover actionable insights, enabling manufacturers to fine-tune production processes with pinpoint accuracy. Edge analytics, on the other hand, facilitates immediate data processing at the source, reducing latency and ensuring critical decisions are made without delay. Cloud computing provides the scalability needed to manage extensive networks of connected devices, allowing for centralized oversight even in sprawling global operations. This powerful combination ensures that IoT isn’t just a standalone solution but part of a broader ecosystem designed to tackle the complex demands of modern industrial environments with efficiency.

Beyond operational improvements, the integration of these technologies aligns with broader goals such as sustainability and cost reduction, which are increasingly vital in today’s market. IoT systems, supported by AI-driven insights, help monitor energy consumption and identify areas for optimization, cutting utility expenses while reducing environmental impact. Governments and regulatory bodies often incentivize such initiatives, making the adoption of green practices not just ethical but financially rewarding. Furthermore, the ability to analyze data in real time through edge and cloud solutions means manufacturers can respond swiftly to inefficiencies, minimizing waste in both materials and time. This holistic approach demonstrates how technology convergence transforms challenges into opportunities, positioning IoT as a linchpin for achieving long-term profitability while meeting societal expectations for responsible industrial practices in a resource-conscious world.

Key Market Segments Fueling Exponential Growth

Delving into the structure of the IoT in manufacturing market reveals distinct segments that are pivotal to its rapid expansion, each addressing unique operational needs with tailored solutions. Currently, solutions encompassing analytics and automation tools are projected to account for 54.2% of total revenue, highlighting their dominance in optimizing factory performance through real-time insights. Services also play a crucial role, with network management expected to contribute 27.9% and managed services 31.6% of revenue, ensuring robust connectivity and scalability for complex IoT deployments. In terms of applications, automation control and management hold a significant 19.3% share, underscoring their importance in streamlining processes and eliminating inefficiencies. These figures reflect a market driven by diverse yet interconnected components, each enhancing the overall effectiveness of IoT in transforming industrial operations into smarter, more responsive systems.

Focusing on industry verticals, discrete manufacturing stands out with a commanding 57.6% market share, fueled by software-defined infrastructure that enables precise and agile production tailored to specific demands. This segment’s reliance on IoT for data-driven innovation allows for customization at scale, a critical advantage in competitive sectors like automotive and electronics. Unlike process manufacturing, which focuses on continuous output, discrete manufacturing benefits from IoT’s ability to manage distinct production cycles with high accuracy. The variation across segments and applications illustrates the versatility of IoT, as it adapts to different challenges—from maintaining network integrity to refining assembly lines. As adoption grows, these segments will likely continue to evolve, driven by technological advancements and the pressing need for efficiency, shaping a market that’s as dynamic as the factories it serves with cutting-edge digital tools.

Navigating Future Opportunities and Challenges

Looking ahead, the trajectory of IoT in manufacturing promises sustained growth, with the market expected to climb to USD 603.9 billion by 2029 before reaching USD 1,375.1 billion by 2035, reflecting the deep integration of automation and data-centric strategies. This expansion will be driven by ongoing advancements in AI and IoT synergies, which promise to further refine predictive maintenance and operational agility. However, challenges such as cybersecurity risks loom large, as the proliferation of connected devices increases vulnerability to breaches that could disrupt entire production lines. Addressing these threats requires robust security protocols and continuous investment in infrastructure to support large-scale deployments. Manufacturers must also prioritize education and training to ensure staff can fully leverage IoT’s potential, turning technical complexity into a competitive edge rather than a barrier to progress in an increasingly digital industrial landscape.

Reflecting on the journey so far, the strides made in embedding IoT within manufacturing underscore a pivotal shift that tackles inefficiencies head-on while paving the way for sustainable practices. The emphasis on smart factories has proven instrumental in reducing costs and enhancing productivity across diverse sectors. To build on this momentum, stakeholders need to focus on scalable solutions that address cybersecurity and infrastructure gaps, ensuring seamless adoption. Collaborative efforts between technology providers and manufacturers could accelerate innovation, while policy support for green initiatives would sustain the drive toward eco-friendly operations. As the industry moves forward, prioritizing adaptability and resilience in IoT strategies emerges as a critical step, ensuring that the transformative power of connected technologies continues to redefine manufacturing for years to come with lasting impact.