In a landmark move poised to redefine the application of artificial intelligence across the industrial sector, chipmaker NVIDIA and French industrial software leader Dassault Systèmes have announced a comprehensive strategic partnership aimed at establishing a new paradigm for how complex industrial systems are designed, simulated, and operated. The central goal of this collaboration is the creation of “Industry World Models”—sophisticated, physics-grounded AI systems capable of simulating everything from intricate drug molecules to the operational dynamics of entire factories. This ambitious venture seeks to move beyond the current landscape of generative AI, which is largely dominated by language-based models, by introducing AI that fundamentally understands and operates according to the laws of the physical world. This initiative represents a significant enterprise AI effort, aiming to usher in an era where digital simulations are not just predictive but are deeply rooted in the foundational principles of science and engineering.

A Union of Digital Twins and Accelerated Computing

The announcement, made jointly by the CEOs of both companies at the 3DEXPERIENCE World conference, signals a unified vision for the future of industrial technology by integrating two powerful, complementary technologies. On one side is Dassault Systèmes’ renowned Virtual Twin technology, a cornerstone of its 3DEXPERIENCE platform, which creates highly detailed and accurate digital replicas of physical assets and systems used across major industries like aerospace, automotive, and manufacturing. These virtual twins are more than just models; they are dynamic, data-rich environments that mirror the real world. On the other side is NVIDIA’s formidable accelerated computing stack, including its Omniverse platform for creating and operating 3D simulations and its powerful AI chips. This combination aims to infuse Dassault’s scientifically validated digital environments with the massive parallel processing power required to run next-generation AI, setting the stage for simulations of unprecedented scale and fidelity.

By merging Dassault’s rich repository of validated scientific and engineering data with NVIDIA’s computational prowess, the two companies aim to create AI systems that are not merely predictive but are deeply rooted in scientific principles. This approach transforms artificial intelligence into a “force multiplier for human ingenuity” by grounding it in a vast body of validated industrial knowledge. This initiative is being framed as the “next frontier of artificial intelligence,” a concept termed “Physical AI.” This new class of AI is designed to learn from and interact with physics-based simulations, enabling it to understand cause and effect in the physical world. The goal is to develop AI that can reason about complex systems, optimize designs, and control manufacturing processes with a level of understanding that far exceeds the capabilities of current-generation AI models, which often lack a fundamental grasp of physical constraints.

A Deeply Integrated Reciprocal Partnership

A particularly distinctive feature of this alliance is its reciprocal nature, which involves tangible infrastructure commitments from both parties that go far beyond a simple technology licensing agreement. Dassault Systèmes is set to deploy its own “AI factories” through its OUTSCALE cloud brand. These facilities, strategically located across three continents to ensure data sovereignty and protect intellectual property, will be powered by NVIDIA’s latest-generation hardware. This will enable Dassault to run advanced AI models directly within its 3DEXPERIENCE platform, offering its customers powerful, integrated AI capabilities without needing to manage their own complex hardware infrastructure. This move democratizes access to high-performance AI, embedding it directly into the engineering and design workflows that millions of professionals already use daily. The deployment of dedicated AI factories demonstrates a long-term commitment to making physical AI a core component of its software ecosystem.

In a rare display of mutual adoption at this scale, NVIDIA will, in turn, leverage Dassault’s model-based systems engineering (MBSE) tools to design and optimize its own future AI factories. The first application of this will be for the development of NVIDIA’s upcoming Rubin platform, which will be integrated into the NVIDIA Omniverse DSX Blueprint for deploying large-scale AI infrastructure. This two-way street of adoption underscores a deep, shared commitment to building a unified ecosystem where the tools being developed are also the tools being used to innovate. By using Dassault’s software to architect its own cutting-edge hardware facilities, NVIDIA is not only validating the platform’s capabilities but also creating a powerful feedback loop that will drive further improvements and integrations. This symbiotic relationship ensures that both companies are deeply invested in the success and evolution of the combined platform, creating a powerful engine for industrial innovation.

The Four Pillars of Technical Integration

The technical integration of this partnership is meticulously structured across four primary domains, each targeting a critical stage of the industrial lifecycle and demonstrating the breadth of the collaboration’s ambition. The first pillar focuses on biology and materials science, where the collaboration will combine NVIDIA’s BioNeMo platform for generative AI in drug discovery with Dassault’s BIOVIA platform. This fusion is designed to significantly accelerate the process of molecular discovery and materials research. By leveraging generative AI, scientists will be able to simulate and analyze complex biological systems with unprecedented speed and accuracy, potentially reducing the time and cost associated with developing new medicines and advanced materials. The second pillar targets engineering and design by enhancing Dassault’s industry-standard SIMULIA simulation software with NVIDIA’s CUDA-X microservices. This will empower engineers to perform complex multi-physics simulations and receive near-instantaneous feedback on design performance, drastically reducing the hours or even days traditionally required for such calculations and enabling more rapid design iteration.

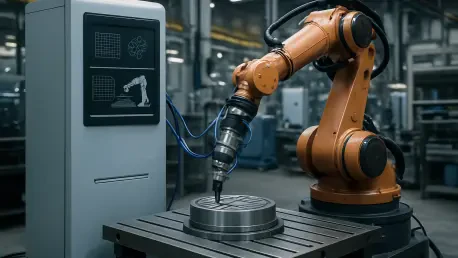

Building on this foundation, the partnership will also integrate NVIDIA’s Omniverse physical AI libraries into Dassault’s DELMIA platform for manufacturing and operations management. This third pillar will facilitate the creation of autonomous, software-defined production systems. These “smart factories” will be able to run continuous simulations of their own operations, allowing for real-time optimization, predictive maintenance, and enhanced efficiency on the factory floor. The fourth and perhaps most forward-looking aspect of the collaboration is the development of “virtual companions.” These are specialized AI agents, powered by NVIDIA’s Nemotron open models, that will reside within the Dassault 3DEXPERIENCE platform. Unlike general-purpose AI assistants, these companions will be trained on specific, industry-relevant data, enabling them to provide engineers and designers with trusted, actionable intelligence that respects the complex constraints and requirements of their domain. The aim is to create AI collaborators that can assist in tasks ranging from design synthesis to compliance verification.

Architecting the Future of Industrial AI

The initiative had already garnered positive reactions from industry leaders who saw tangible benefits in this physics-first approach to AI. The CEO of Bel Group highlighted the potential to gain the computational power needed to model products at scale, thereby accelerating innovation while meeting sustainability goals. An executive from the automation giant OMRON emphasized how the combination of technologies would allow manufacturers to move from design to deployment with greater speed and confidence. Similarly, Lucid Motors’ Vice President of Digital noted the potential for these physics-informed AI models to significantly compress vehicle development cycles without compromising predictive accuracy. Even research institutions like the National Institute for Aviation Research (NIAR) had begun testing the virtual companions for aircraft design, with its director pointing to their ability to accelerate the creation of compliant virtual aircraft twins. These early endorsements from diverse sectors suggested a significant market appetite for this grounded, intelligent approach to industrial transformation.

This partnership ultimately represented a strategic effort by both NVIDIA and Dassault Systèmes to establish a standardized architecture for industrial AI. It served as a crucial move for both companies: for NVIDIA, it was a chance to demonstrate the value of its technology beyond the consumer-facing AI boom, and for Dassault, it was a way to prove that its established engineering platforms were at the forefront of the AI era. By architecting AI systems from the ground up with physics and scientific validation at their core, they were betting that the future of industrial innovation lay not in retrofitting generic models but in building mission-critical systems that industries could trust. The ultimate success of this venture would depend on whether manufacturers adopted these systems for their core operations and if the economic benefits materialized at scale. However, the comprehensive integration and strong initial industry support signaled that a new chapter for industrial intelligence had firmly begun.