A recent multi-million RMB financing round for Hanao Intelligence, a specialized equipment manufacturer, has sent ripples through the high-end manufacturing sector, signaling a deliberate push to industrialize a technology that could fundamentally alter the global landscape. This capital injection, led by the prominent domestic investment institution Guozhong Capital, is more than a corporate success story; it represents a strategic maneuver aimed at achieving technological sovereignty in a domain long dominated by foreign entities. The company’s focus on electrochemical milling is being positioned as a critical tool to break this dependency and secure the nation’s industrial supply chain for essential components in aerospace, energy, and beyond. This development poses a significant question about the future balance of power in the world of advanced industrial production, suggesting a potential shift in the technological hierarchy that has defined modern manufacturing for decades.

A Technological Gambit on Electrochemical Precision

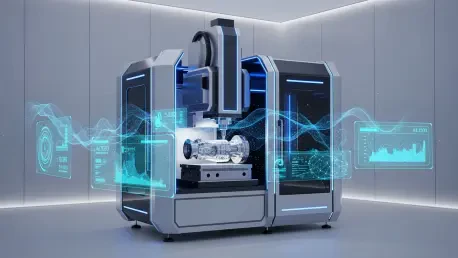

At the heart of Hanao Intelligence’s strategy lies electrochemical milling, an advanced processing method that dissolves material atom by atom rather than relying on the brute force of traditional cutting. This technique offers profound advantages, producing components with exceptionally high-quality surfaces, completely free from the micro-cracks and residual stress that can compromise the integrity of parts made through conventional machining. Its unique ability to effortlessly shape notoriously difficult-to-cut materials, such as titanium alloys and high-temperature superalloys, makes it indispensable for manufacturing the most demanding high-performance parts for civil aviation engines, gas turbines, and sophisticated medical devices. Despite these clear benefits, China has historically lagged in the industrialization and productization of this technology, a critical gap that has allowed foreign brands to monopolize the lucrative high-end market segment for years, leaving domestic industries vulnerable to external supply chain disruptions.

Founded in 2021 by a veteran team hailing from the esteemed Hanchuan Machine Tool, Hanao Intelligence was established with the explicit mission to close this technological void. Drawing on decades of deep experience in high-end machine tool research and development, the company has rapidly engineered a complete and mature product portfolio. This includes advanced vertical and horizontal five-axis linkage electrochemical milling machining centers, as well as more complex multi-axis composite machines. Its progress has been validated through its wholly-owned subsidiary, which has already earned recognition as a national high-tech enterprise. More importantly, its equipment has achieved successful batch application within the demanding aerospace and gas turbine manufacturing sectors. Customers in these fields have praised the machinery for its consistent process stability, high efficiency, and overall cost-effectiveness, proving its readiness for critical industrial roles and establishing its credibility in a highly competitive market.

Addressing a National Strategic Imperative

The significance of Hanao’s work is magnified by the broader context of China’s national industrial strategy, which is driving an accelerated transformation toward more intelligent and precise manufacturing. At the apex of this evolution are five-axis linkage CNC machine tools, often called “industrial mother machines,” which are indispensable for producing the complex geometries required in strategic sectors. Market data reveals the urgency of this mission: while China’s domestic CNC market is valued at approximately 200 billion RMB, the high-end segment—a market worth 20-30 billion RMB—is overwhelmingly dominated by foreign brands, which control up to 90% of the market share. Domestic enterprises have historically struggled to compete in critical areas like long-term stability and composite processing capabilities. Hanao’s fusion of electrochemical milling with multi-axis linkage directly confronts these pain points, offering a potent domestic solution for a critical national need and promising to reclaim market share from international competitors.

Hanao Intelligence has constructed its competitive advantage on an integrated, dual-drive model of “self-developed core components + overall process delivery.” This holistic approach ensures profound control over both quality and performance. The company independently develops and manufactures its own key functional components, including specialized spindles designed for electrochemical milling, high-precision multi-axis turntables, and intelligent electrolyte circulation systems. Crucially, Hanao also conducts in-depth secondary development at the CNC system level, achieving a seamless integration of electrochemical process parameters with multi-axis motion control. This level of synergy, difficult to replicate with off-the-shelf components, gives its machines a distinct performance edge. This technical prowess is manifested in two main product series: the “High-Rigidity Electrochemical Milling Platform” for large structural parts and the “Multi-process Composite Electrochemical Milling Machine” for streamlined, efficient production workflows.

Charting a Course for Industrial Leadership

The newly secured financing will be strategically deployed across three pivotal areas designed to propel the company into its next phase of significant growth. A substantial portion of the funds is allocated for technology iteration and product expansion, driving continuous performance optimization of existing five-axis machining centers while financing the development of more complex, next-generation models like six-axis and seven-axis machines. Another key focus will be the expansion of the company’s proprietary process database for critical applications in aerospace, automotive, and medical industries. The capital will also enable a significant expansion of mass-production capacity for its core models. Concurrently, Hanao plans to establish an independent supply chain for its key functional components, a crucial step toward enhancing delivery efficiency, ensuring product consistency, and reducing external dependencies for a more resilient operation in an unpredictable global market.

Through this strategic capital infusion, Hanao Intelligence laid a definitive foundation for a systemic upgrade within China’s high-end manufacturing sector. The founder articulated a vision that progressed beyond merely creating “multi-axis” machines, aiming instead for fully “composite and intelligent” systems that could elevate the domestic industry from a position of “following” international leaders to one of “parallel running” and, eventually, “leading.” The company committed to a significant increase in its R&D investment, focusing on the deep integration of its core technology with next-generation information systems like artificial intelligence and the Internet of Things. This strategic direction involved building digital platforms for remote operation and maintenance, AI-driven process optimization, and intelligent parameter adjustment, which together formed a comprehensive intelligent equipment ecosystem that promised to redefine the future of high-end industrial production.