The Internet of Things is no longer a futuristic concept whispered about in boardrooms; it has firmly planted itself on the factory floor as the bedrock of a paradigm shift known as Industry 4.0, or smart manufacturing. This technological evolution represents a fundamental reshaping of industrial operations, marking a definitive transition from the traditional, reactive factories of the past—characterized by siloed mechanical systems and manual processes—to dynamic, data-rich environments where machines communicate seamlessly, processes self-optimize in real-time, and strategic decisions are driven by a constant stream of predictive analytics. This is not merely an incremental improvement or a minor upgrade to existing systems; it is a complete game-changer that is actively creating a new divide in the industrial landscape, separating agile market leaders from companies that risk being left behind. As forecasts predict that IoT can increase manufacturing productivity by as much as 25% while reducing maintenance costs by 40%, the adoption of smart technology has become the primary differentiator between sustained growth and impending obsolescence in the modern competitive arena.

Understanding the Smart Factory Transformation

The Core Components of an IoT Ecosystem

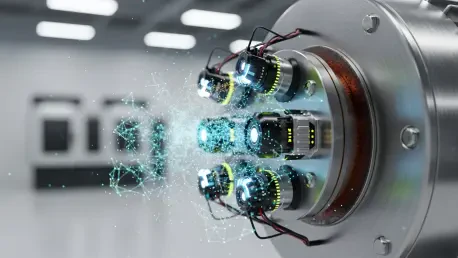

At the heart of any smart manufacturing operation are its sensors, which function as the digital nerve endings of the factory. These small yet powerful devices form the foundational layer of the entire IoT ecosystem, tasked with the critical responsibility of continuously gathering raw data about a vast array of physical conditions. They meticulously monitor and quantify every crucial variable, from the temperature of a furnace and the pressure within a hydraulic system to the subtle vibrations of a motor and the precise location of assets moving across the facility. In essence, these sensors act as translators, converting the tangible, physical world of the factory floor into a comprehensive and uninterrupted digital data stream. This constant flow of information provides the raw material for every subsequent analysis and decision. Once this immense volume of data is collected, it requires a central processing unit—a role fulfilled by cloud platforms. Acting as the “brain” of the operation, these robust systems are designed to ingest, securely store, and perform the heavy computational work necessary to manage the torrent of data pouring in from potentially thousands of sensors. They provide the scalable infrastructure needed to turn a cacophony of data points into a structured resource, paving the way for the emergence of true operational intelligence.

The final and most transformative component of the IoT ecosystem is its suite of analytics tools, which can be thought of as the “consciousness” of the entire system. Often powered by sophisticated artificial intelligence and machine learning algorithms, these tools are what bring the data to life. They sift through the vast datasets processed by the cloud, meticulously identifying hidden patterns, detecting subtle anomalies that would be invisible to the human eye, and generating highly accurate predictive insights. This is where the true value of IoT is unlocked. The system transitions from simply reporting on what has already happened to forecasting what is likely to happen next, enabling a proactive rather than reactive approach to management. These analytics transform the raw data from a historical record into a powerful tool for strategic foresight, providing clear, actionable intelligence that empowers decision-makers to optimize processes, preempt problems, and steer the factory’s future with a level of precision that was previously unimaginable. This three-part structure—sensors, cloud, and analytics—forms a synergistic loop that continuously learns and improves, driving the factory toward peak performance.

A New Business Paradigm From Product to Service

Perhaps the most profound and strategic impact of the Internet of Things is its remarkable ability to fundamentally transform long-standing business models, moving companies away from transactional product sales toward long-term, service-based relationships. The classic and most illustrative example of this pivot is Rolls-Royce’s jet engine division, which masterfully leveraged IoT to redefine its value proposition. Instead of simply selling powerful and expensive jet engines to airlines, the company embedded its products with thousands of sensors capable of collecting trillions of data points on performance, wear, and environmental conditions. This rich data stream allowed Rolls-Royce to offer a revolutionary service: “power by the hour.” Under this subscription-style model, airlines pay for the operational uptime of the engines rather than owning the hardware outright. Rolls-Royce, in turn, takes full responsibility for predictively maintaining the engines, optimizing their performance remotely, and strategically replacing parts well before they are at risk of failure. This strategic shift did more than just create a new revenue stream; it perfectly aligned the company’s success with its customers’ core operational needs, effectively turning a high-cost capital good into a reliable, outcome-based service that guarantees performance and minimizes downtime for the airlines.

This transition to a service-oriented model, often called “servitization,” provides a formidable and sustainable competitive edge that is difficult for rivals to replicate. By embedding services directly into the product lifecycle, companies can create deep, long-term partnerships with their clients, effectively locking in customers with ongoing agreements that foster loyalty and generate predictable, recurring revenue streams. This model shifts the customer relationship from a one-time transaction to a continuous collaboration, where the manufacturer becomes an indispensable partner in the customer’s operational success. Furthermore, it changes the financial dynamic for the customer, converting a massive, upfront capital expenditure into a more manageable and predictable operating expense. This approach not only enhances customer value but also provides the manufacturer with invaluable real-world data that can be used to inform future product designs, improve existing services, and identify new opportunities for innovation. In this new paradigm, the product is no longer the endpoint but rather the platform for delivering continuous, data-driven value throughout its entire operational life.

The Tangible Benefits of IoT Implementation

The Revolution in Maintenance and Operations

One of the most immediate, tangible, and powerful benefits realized through the implementation of IoT in a manufacturing setting is the complete revolution in maintenance strategy. This marks a definitive shift away from outdated and inefficient practices. The old, reactive mantra of “if it ain’t broke, don’t fix it” has long been recognized as a significant liability, leading to unexpected and often catastrophic equipment failures that halt production and incur massive costs. Even the more advanced strategy of preventive maintenance, which involves servicing equipment on a fixed schedule, is inherently wasteful, as parts are often replaced unnecessarily or not replaced soon enough. IoT ushers in the era of predictive maintenance, where the guiding principle becomes “fix it right before it breaks.” By leveraging a network of sensors, sophisticated algorithms can continuously analyze the operational data of a machine—monitoring its temperature, vibrations, energy consumption, and acoustic signature—to detect the earliest signs of degradation. This allows the system to accurately predict potential failures days or even weeks in advance, transforming maintenance from a reactive emergency response into a planned, strategic activity that minimizes disruption and maximizes asset lifespan.

The automotive giant BMW offers a compelling real-world case study of this principle in action. By deploying sensors across its assembly lines, the company gathers continuous data streams that are fed into advanced analytical models. These algorithms are trained to recognize the subtle patterns that precede equipment failure, allowing maintenance teams to intervene proactively. This foresight has enabled BMW to slash unexpected downtime by as much as 50%, a monumental achievement in an industry where every minute of lost production translates to significant financial loss. This predictive capability allows for repairs to be scheduled during non-peak hours or planned shutdowns, ensuring that production flow is not interrupted. Furthermore, necessary replacement parts can be ordered with standard shipping well in advance, eliminating the high costs associated with emergency procurement. The result is a dramatic reduction in operational costs, an increase in overall equipment effectiveness, and a more stable, predictable manufacturing environment where disruptions are the exception rather than the rule.

Enhancing Quality Efficiency and Sustainability

Beyond maintenance, the Internet of Things enables a new level of real-time quality control that catches issues at their inception, preventing widespread problems and ensuring product consistency. On its high-speed bottling lines, for instance, Coca-Cola deploys a sophisticated network of sensors to meticulously track critical parameters such as temperature, carbonation levels, and fill volumes with split-second accuracy. If any of these variables deviate even slightly from the predefined specifications, the system can instantly flag the anomaly. This immediate feedback loop allows operators to correct the issue before a large batch of defective products is produced, drastically minimizing waste, reducing the risk of costly and brand-damaging recalls, and guaranteeing that every product that leaves the factory meets the company’s stringent quality standards. In industries requiring even greater precision, such as semiconductor manufacturing, Intel integrates artificial intelligence with high-resolution imaging systems. This advanced IoT application can automatically detect microscopic defects on microchips that are entirely invisible to the human eye, ensuring a level of automated, 24/7 quality assurance that is critical for maintaining high production yields and delivering the flawless performance that modern electronics demand.

In parallel with quality improvements, smart sensor networks are instrumental in uncovering significant hidden inefficiencies, leading to substantial cost savings and a more sustainable operational footprint. Many manufacturers are unaware of the energy wasted by their machinery until it is quantified by an IoT system. In one notable case, an auto parts manufacturer discovered through its new monitoring platform that a staggering 30% of its total energy costs were attributable to equipment that was left idling overnight and on weekends. This “invisible” waste, once identified, became an immediate and easy target for optimization, resulting in a dramatic reduction in utility bills and a smaller environmental impact. This capability is becoming increasingly critical as environmental regulations grow more stringent. Real-time tracking of emissions, water usage, and other resources is transitioning from a best practice to a non-negotiable requirement for compliance. Industrial IoT provides the precise, verifiable data needed to meet these evolving standards, helping companies avoid hefty fines, demonstrate corporate responsibility, and build more resilient, efficient, and sustainable operations for the future.

Gaining Unprecedented Supply Chain Visibility

In today’s intricate and globally distributed manufacturing landscape, the ability to know the precise location and status of assets at any given moment is a critical competitive advantage. The Internet of Things provides this capability through comprehensive, real-time tracking systems that offer unprecedented visibility across the entire supply chain. By affixing IoT-enabled sensors to individual pallets, shipping containers, and even high-value components, companies can achieve complete end-to-end transparency, monitoring the journey of materials from the moment they leave a supplier’s warehouse to the instant they arrive on the factory floor. Honeywell, for example, leverages this technology to create a seamless and predictable flow of materials, effectively eliminating the common production stoppages that occur when a crucial part is lost, misplaced, or unexpectedly delayed in transit. This granular level of oversight transforms the supply chain from a series of opaque and disconnected steps into a transparent, synchronized system. It also mitigates the need for large “just-in-case” safety stocks, allowing for a leaner and more capital-efficient inventory management strategy while simultaneously ensuring that the assembly line is always supplied with the necessary components at the right time.

The broader implications of a fully transparent supply chain extend far beyond preventing material shortages. This newfound visibility empowers manufacturers to become far more agile and responsive to the inevitable disruptions that characterize modern logistics, such as adverse weather events, port congestion, or geopolitical instability. With real-time data on the location and condition of shipments, logistics managers can dynamically reroute assets, adjust production schedules, and proactively communicate with customers to manage expectations. Furthermore, this rich data stream can be fed into advanced analytics platforms to improve demand forecasting, optimize shipping routes, and enhance collaboration with suppliers and logistics partners. The supply chain evolves from a rigid, linear process into a highly responsive and integrated network. This deep level of insight enables manufacturers to operate on a much leaner basis, significantly reduce lead times, and ultimately improve customer satisfaction by providing more accurate delivery timelines and a higher level of service reliability, creating a more resilient and efficient value chain from end to end.

Building the Connected Future

The Rise of the Interconnected Ecosystem

The established, linear manufacturing model—a simple chain progressing from supplier to factory to customer—is rapidly dissolving. In its place, a far more complex, dynamic, and interconnected ecosystem is emerging, one that functions less like a rigid chain and more like a living, intelligent organism. In this new paradigm, suppliers, strategic partners, and even end customers are no longer siloed entities but are deeply integrated into shared, real-time data streams. This fosters a level of collaboration, visibility, and agility that was previously unattainable. Companies at the forefront of this movement are actively building the platforms that enable this transformation. Siemens, for example, is pioneering the use of “digital twins”—highly detailed virtual replicas of physical assets and entire production processes. These digital models are continuously updated with real-world sensor data, allowing engineers to monitor performance, run simulations of potential changes, and optimize operations in a virtual environment before implementing them on the factory floor. This capability dramatically reduces risk and accelerates the pace of innovation. By creating a shared digital reality, these platforms break down the traditional barriers between internal departments and external partners, fostering a new era of co-creation and collective efficiency that spans the entire value chain.

This evolution is not merely about connecting machines within a single factory; it is about creating a vast, intelligent network that unifies production, maintenance, and broader business systems into a cohesive whole. Rockwell Automation champions this vision with its “Connected Enterprise” concept, which aims to integrate plant-floor operational technology (OT) with enterprise-level information technology (IT). This convergence breaks down the long-standing silos that have separated business decision-makers from the realities of the production environment. For instance, in the highly regulated food and beverage industry, this level of integration enables meticulous traceability from farm to fork, ensuring compliance with strict safety standards and allowing for rapid response in the event of a public health concern. Similarly, Hitachi Vantara focuses on data intelligence, using its Lumada platform to process massive, diverse datasets and uncover insights that would be impossible for humans to detect. This data-driven approach allows for the optimization of the entire ecosystem, ensuring that every decision, from raw material procurement to final product delivery, is informed by the most current and comprehensive information available, creating a truly synchronized and intelligent manufacturing network.

An Urgent Call for Digital Evolution

The evidence gathered from early adopters decisively demonstrated that smart manufacturing, powered by the Internet of Things, was not a fleeting trend but the new baseline for competitive survival and market leadership. Companies that embraced this technological shift, such as General Motors and General Electric, reaped substantial rewards that were measured in tangible outcomes. They witnessed double-digit productivity gains, achieved significant reductions in operational costs, and slashed unplanned downtime by as much as 30%, fundamentally strengthening their positions in the global marketplace. The path forward pointed toward even more advanced capabilities that once seemed like science fiction, including the development of self-learning factories that could autonomously optimize their own processes, the use of localized 3D printing to create spare parts on demand, and the widespread application of digital twins and holographic interfaces for remote collaboration and training. The central message that emerged was one of profound urgency. The conversation in executive suites had shifted entirely; the question was no longer if a company should implement IoT, but rather whether it could do so before its competitors had already established an insurmountable lead by moving on to the next technological frontier. Companies that continued to deliberate risked becoming cautionary tales of obsolescence, much like the video rental stores that hesitated in a world rapidly being reshaped by streaming services.