The centuries-old art of stonework, traditionally defined by the skilled hand of the artisan, is undergoing a profound transformation driven by digital innovation. In North Atlanta, one company is at the forefront of this evolution, demonstrating that the future of custom stone fabrication lies in the seamless integration of engineering excellence and aesthetic sophistication. Legacy Countertops, a prominent Alpharetta, Georgia-based firm, has announced a significant investment in a comprehensive digital workflow and advanced Computer Numerical Control (CNC) technology. This strategic move is set to redefine industry standards by fundamentally changing how high-end stonework projects are conceptualized, crafted, and delivered. The company’s President and Owner, Andres Varvaro, emphasizes that this is far more than a simple equipment upgrade; it represents a complete overhaul of their operational philosophy, aimed at eliminating the variables that compromise quality and unlocking new levels of precision that were previously unattainable. This initiative merges meticulous digital planning with automated execution, promising a new benchmark for quality and efficiency in the competitive custom countertop market.

A New Era of Precision Fabrication

The Digital Workflow Revolution

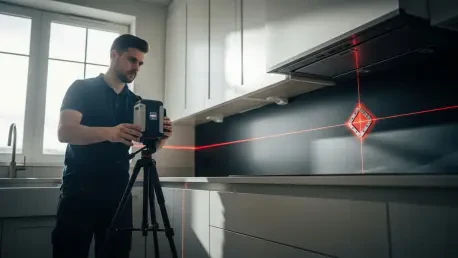

The foundation of this technological leap lies in an end-to-end digital process that begins long before a slab of stone is touched by a cutting tool. The workflow commences on-site with laser-accurate digital templating, a method that captures the precise dimensions and nuances of a space with unparalleled exactitude, replacing traditional manual measurement techniques that are prone to error. These detailed digital blueprints are then used to create an immersive 3D project visualization. This critical step allows clients, designers, and architects to review a virtual model of the final product, enabling them to see how stone patterns will align, how edges will meet, and how the overall piece will integrate into their environment. This pre-visualization phase is instrumental in ensuring complete alignment on the design vision, allowing for adjustments and refinements before any material is committed. The finalized digital model serves as the direct instruction set for the fabrication machinery, creating a closed-loop system where the initial vision is translated into a physical reality without deviation or manual interpretation, ensuring the final product is a perfect match to the approved design.

Unprecedented Accuracy and Speed

Once the digital plans are finalized, they are fed directly into the advanced CNC fabrication equipment, which executes the cutting, shaping, and polishing with micron-level accuracy. This computer-controlled process effectively eliminates the potential for human error, resulting in consistently flawless outcomes. The precision of the machinery ensures that every cut is perfect, every edge profile is exact, and every joint is seamless, contributing to a superior finished product. Beyond the significant leap in quality, this technology dramatically accelerates project timelines. The efficiency of automated fabrication compresses production cycles by as much as 40%, a substantial improvement that translates directly to faster project completion and installation for residential and commercial clients alike. This newfound speed does not come at the expense of quality; rather, it is a byproduct of a more controlled and predictable manufacturing environment. The ability to produce complex designs quickly and accurately establishes a new standard for service delivery, meeting the increasing demand for rapid turnarounds in today’s construction and renovation markets.

Tangible Benefits and Expanded Capabilities

Optimizing Resources and Reducing Waste

A key advantage of this integrated digital system is its remarkable efficiency in material management, which yields significant environmental and economic benefits. At the heart of this optimization is a sophisticated digital nesting software that analyzes the digital cut list for a project and strategically arranges the pieces on a virtual representation of the stone slab. This process is designed to maximize material yield, fitting the required components together like a complex puzzle to minimize leftover stone. This zero-waste approach not only reduces the amount of raw material needed for a project, thereby lowering costs for the client, but it also minimizes the environmental impact associated with quarrying and transporting stone. Furthermore, this system ensures scalable consistency across all projects. Whether fabricating a single kitchen island or producing hundreds of identical vanities for a large commercial development, the CNC technology guarantees that every piece is manufactured to the exact same high standard. This level of replicability is crucial for commercial clients and provides peace of mind for homeowners seeking perfection.

Redefining Design Possibilities

The adoption of CNC technology has also shattered previous design limitations, empowering designers and clients to explore more intricate and ambitious concepts without a prohibitive increase in cost. Complex features that were once labor-intensive and expensive to produce with manual techniques are now standard, cost-effective offerings. This includes creating elegant waterfall panels where the countertop surface appears to flow seamlessly down the side of a cabinet, or executing perfect book-matched slabs where the vein patterns of two adjoining pieces of stone mirror each other to create a stunning symmetrical effect. Detailed and ornate edge profiles, which require meticulous shaping, can be programmed and executed with flawless precision. This expansion of design capabilities means that aesthetic vision is no longer constrained by the practical limits of fabrication. The technology fosters a more collaborative and creative environment, allowing for the realization of unique, custom-tailored designs that elevate the artistry of stonework and make high-end features more accessible to a broader range of projects.

A Foundation Built on Innovation

Through its strategic investment in a fully digital workflow and advanced CNC fabrication, Legacy Countertops solidified its position as a forward-thinking leader in the North Atlanta stonework industry. The company, which had already built a strong reputation over 15 years with more than 10,000 completed projects and a BBB accreditation, successfully leveraged technology to enhance its core commitment to quality and service. The integration of these systems did more than just improve efficiency; it fundamentally elevated the standard for precision, consistency, and design potential in the fabrication of granite, quartz, quartzite, porcelain, and marble. By controlling the entire process in-house—from design and digital templating to fabrication and installation—the firm established a new benchmark for delivering complex, high-quality projects for both its residential and commercial clientele. This decisive step demonstrated how embracing innovation was essential not only for maintaining a competitive edge but also for truly advancing the craft of stonework itself.