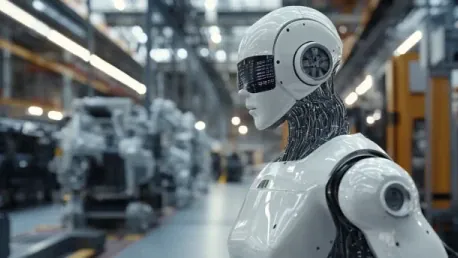

As we delve further into the age of technological advancement, manufacturers are increasingly adopting artificial intelligence to maintain and enhance their competitive standing in the market. This shift, highlighted in industry reports, emphasizes the need for modern manufacturers to integrate advanced technologies into their operations while simultaneously grappling with a range of challenges and growing concerns over data privacy. Understanding these dynamics is crucial for stakeholders aiming to navigate the evolving manufacturing landscape successfully.

Prioritizing AI and Digital Transformation

Enhancing Efficiency and Optimizing Supply Chains

Manufacturers have recognized the vital role artificial intelligence plays in driving efficiency and optimizing operations. AI technologies enable companies to analyze vast amounts of data quickly, leading to more informed decision-making processes. This capability is particularly crucial in managing supply chains, where disruptions can have far-reaching implications. Advanced AI algorithms can predict potential supply chain bottlenecks, mitigate risks, and enhance overall productivity.

By leveraging AI, manufacturers can also improve product quality through more precise forecasting and real-time monitoring. Predictive analytics allows manufacturers to anticipate maintenance needs, thus minimizing downtime and extending the lifespan of machinery. As a result, manufacturers can create a more resilient and responsive production system.

Navigating the Digital Transformation Landscape

The integration of AI is part of a broader digital transformation trend within the manufacturing industry. Companies are embracing smart manufacturing techniques that utilize the Internet of Things (IoT), big data analytics, and cloud computing. These technologies work in tandem to create more agile and adaptable manufacturing processes. The shift towards digital transformation is not merely a technological upgrade but a strategic imperative that enables manufacturers to stay competitive in a rapidly evolving market.

However, this transition is not without its challenges. Manufacturers must invest significantly in updating infrastructure, training the workforce, and ensuring systems’ interoperability. These investments, while substantial, are essential for unlocking the full potential of AI and digital technologies. The success of digital transformation hinges on a company’s ability to manage these complexities and implement change effectively.

Addressing Industry Challenges

Supply Chain Disruptions and Workforce Shortages

One of the most pressing challenges faced by manufacturers is the frequent disruption of supply chains. External factors such as geopolitical tensions, natural disasters, and global health crises can severely impact the availability of raw materials and components. AI-driven supply chain management solutions offer a way to anticipate and mitigate these disruptions by providing real-time visibility and predictive insights.

Additionally, the industry continues to grapple with workforce shortages. The advent of automation and robotics, powered by AI, offers a potential solution by taking over repetitive and labor-intensive tasks. However, this shift necessitates a workforce with new skill sets to manage and maintain advanced technologies. Investment in employee retraining and development programs is critical to address this skills gap and ensure manufacturers can fully harness the capabilities of AI.

Rising Operational Costs and Market Fluctuations

Rising operational costs represent another significant hurdle for manufacturers. Energy prices, raw material costs, and compliance with environmental regulations contribute to increasing production expenses. AI can help mitigate these costs by optimizing resource use and improving energy efficiency. Predictive maintenance and process optimization reduce waste and lower operational expenses over time.

Market demand volatility also poses a challenge, as manufacturers must adapt quickly to changing consumer preferences and economic conditions. AI-driven demand forecasting allows companies to respond more effectively to these fluctuations, ensuring that production aligns with market needs. This adaptability is crucial for maintaining profitability and ensuring long-term growth.

Privacy and Data Protection Concerns

Stricter Regulatory Environments and Data Security

The growing reliance on AI and digital technologies brings heightened concerns about data privacy and protection. Manufacturers must navigate a landscape with increasingly stringent regulatory requirements for data security and user privacy. Compliance with regulations such as GDPR and CCPA is essential to avoid legal repercussions and maintain consumer trust.

Implementing robust data security measures, including encryption, access controls, and regular security audits, is vital to protect sensitive information. Manufacturers must also ensure transparency in data collection and usage practices, obtaining user consent and offering clear explanations of data handling procedures. This approach fosters trust and confidence among consumers and regulatory bodies alike.

Managing Cookies, User Consent, and Data Sharing

The management of cookies and user consent has become a focal point in addressing data privacy concerns. Manufacturers must adopt best practices for obtaining and managing user consent, ensuring that users are informed about the types of data collected and how it will be used. Providing users with control over their data and honoring their privacy preferences is critical in building and maintaining trust.

Data sharing practices also come under scrutiny, particularly in partnerships or collaborations. Manufacturers must establish clear guidelines for data sharing, ensuring that third parties adhere to the same stringent privacy standards. This approach minimizes risks associated with data breaches and misuse, safeguarding both corporate and user data.

Balancing Innovation and Responsibility

Continuous Innovation and Process Enhancement

Manufacturers are in a perpetual state of evolution, striving to innovate continuously in both technology and processes. Embracing a culture of innovation means not only adopting new technologies but also reassessing and refining existing methods. By fostering agility and flexibility, manufacturers can quickly adapt to external pressures and capitalize on emerging opportunities.

The integration of AI and digital transformation requires a holistic approach that includes rethinking business strategies, workforce management, and operational protocols. Manufacturers must establish a robust framework for evaluating and implementing new technologies, ensuring they align with broader business goals. This strategic focus is critical for sustaining growth and remaining competitive in a dynamic market environment.

Future Directions and Strategic Focus

As we progress further into the era of technological advancement, manufacturers are increasingly turning to artificial intelligence to maintain and enhance their competitive edge in the market. Reports within the industry underscore this transition, stressing the necessity for contemporary manufacturers to weave advanced technologies into their operational fabric. Alongside the implementation of AI, manufacturers must also confront an array of challenges, not least of which are growing concerns over data privacy. This dual focus—on integrating cutting-edge technology and safeguarding sensitive information—requires a nimble and thoughtful approach. Stakeholders keen on thriving in the rapidly evolving manufacturing landscape must grasp these dynamics, balancing innovation with the imperative of data security. By understanding these intertwined elements, they can better navigate the complexities and position themselves for sustained success in a highly competitive environment.