The long-promised age of advanced, humanoid robotics has remained stubbornly confined to viral videos and research labs, always seeming just over the horizon. At the Consumer Electronics Show, however, an unexpected contender from the automotive world, Hyundai Motor Group, presented a remarkably

A profound transformation is underway on the world's factory floors, where the sheer volume of data generated by modern machinery now dictates the pace of innovation and efficiency. The global market for Factory Floor Edge AI Industrial PCs (IPCs) is at the epicenter of this shift, poised for a

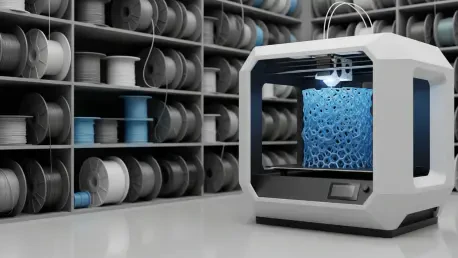

The once-niche world of desktop 3D printing has quietly staged a professional takeover, fundamentally reshaping the manufacturing landscape and setting the stage for a multi-billion dollar market expansion. A new, comprehensive market analysis reveals that the global polymer extrusion 3D printing

The pursuit of micron-level accuracy in today's high-stakes manufacturing environments places an unprecedented focus on every component within the production chain, yet the foundational element of workholding is often underestimated. Advanced workholding systems have evolved far beyond simple

An investigation has been launched into a significant data breach at Legacy Manufacturing Company, an Iowa-based producer of water and air hoses, after it was discovered that sensitive personal information may have been compromised. The incident, which came to light following a network disruption

The modern industrial landscape is facing unprecedented complexity, where even minor inefficiencies can cascade into significant production delays and financial losses, demanding a fundamental shift beyond traditional automation. In a landmark move poised to redefine industrial processes, Siemens