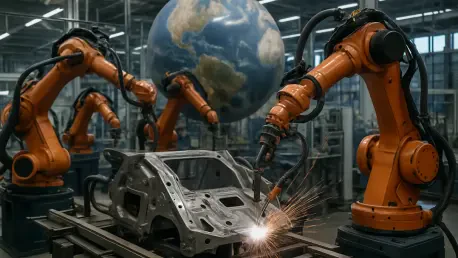

Deep within the industrial heartland of Chongqing, a sprawling factory floor operates in near-total darkness, its silence broken only by the hum and whir of machinery as a new car rolls off the assembly line every sixty seconds. This is the Chang’An Automobile "dark factory," a marvel of modern

The seamless integration of robotics, data analytics, and interconnected systems defines the modern smart factory, yet this picture of technological sophistication is often disrupted by an administrative function still rooted in the past. While the production floor operates with precision and

The immense potential of 3D printing for creating complex structures, from custom medical implants to engineered human tissues, is often hampered by an invisible and ever-present force: gravity. When dealing with soft, fluid-like materials such as bio-inks, Earth's gravitational pull can mask

Siemens' SIMOVE ANS+ navigation software represents a significant advancement in the industrial automation sector, offering a blueprint for the reconfigurable smart factories that are quickly becoming an industry necessity. This review will explore the evolution of this technology, its key

We're joined today by Kwame Zaire, a thought leader in production management with deep expertise in electronics, equipment, and advanced manufacturing. His work on predictive maintenance and quality control offers a critical perspective on the industrial challenges facing high-stakes sectors. We'll

The journey of produce from a sun-drenched field to a sterile supermarket aisle is increasingly managed not by the hands of a farmer but by the cold logic of algorithms, transforming pastoral landscapes into highly controlled, data-driven production zones. Modern agriculture stands at a critical