In a dynamic convergence of robotics and trade, the Robotics Summit recently brought to light both the technological advancements in robotics and the looming challenges posed by geopolitical shifts. Kwame Zaire, an expert in manufacturing, production management, and a thought leader on predictive

In the rapidly advancing realm of artificial intelligence, the specialized data centers supporting AI's evolution are indispensable to the technology's transformative influence across various sectors. These facilities, like OpenAI's expansive "Stargate," are constructed to handle the intensive

In a world increasingly reliant on artificial intelligence, have you ever stopped to ponder the silent giants supporting this massive digital shift? AI data centers, those crucial monuments of technology, buzz tirelessly beneath the surface of our digital activity. Intriguingly, recent estimates

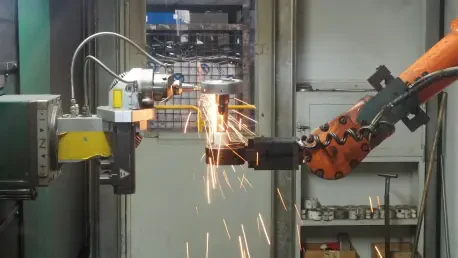

In the ever-evolving industrial landscape, the integration of artificial intelligence (AI) has significantly transformed operations on the modern plant floor. This transformation is not simply about automating existing tasks but rather enhancing and optimizing processes with intelligent insights.

The integration of AI into manufacturing processes has revolutionized the industry, offering significant advantages such as increased efficiency, cost reductions, and enhanced innovation. As companies adopt AI to streamline operations, they face the critical challenge of maintaining robust security

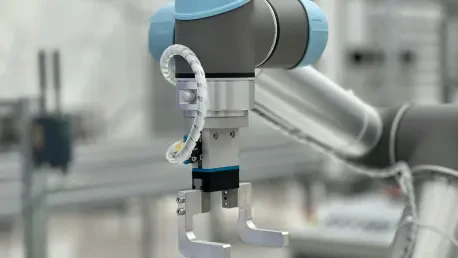

In the ever-evolving landscape of industrial automation, the unveiling of AI-driven cobots represents a groundbreaking shift. As the manufacturing world grapples with labor shortages, this strategic move introduces a solution poised to transform efficiency standards. At the forefront of this change