As robotics technology continues its relentless march forward, creating machines with unprecedented intelligence and complexity, their ultimate effectiveness in the real world is increasingly dictated not by their software but by the precision of their physical hardware. The most advanced control

In a significant strategic maneuver aimed at reshaping the manufacturing landscape, the recent appointment of Dave Evans, co-founder of Fictiv, to the presidency of Misumi Americas has set the stage for a monumental integration effort. This leadership transition, coming just nine months after

With a deep background in production management and a keen focus on the intersection of electronics, equipment, and predictive technologies, Kwame Zaire has become a leading voice in the strategic application of AI on the factory floor. He champions a human-centric approach, guiding manufacturers

The familiar hum of the automotive assembly line is increasingly being orchestrated by a new generation of sophisticated robotic workers, moving far beyond the simple mechanical arms that once defined industrial automation. This review explores the evolution of this technology at Ford Motor

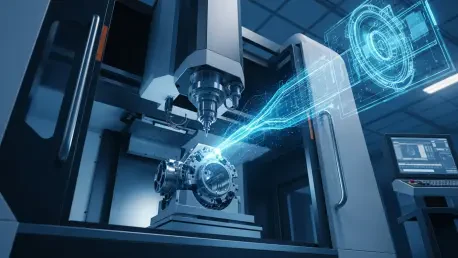

The long-held paradigm of a designer working in isolation with a static digital drafting tool is rapidly giving way to a collaborative ecosystem where artificial intelligence acts as a co-pilot, fundamentally reshaping the creative and engineering landscape. AI-driven Computer-Aided Design (CAD)

The combat readiness of the United States Army's most advanced ground vehicles is currently dictated by a complex web of global logistics, often stretching thousands of miles across contested territories. This intricate system, while a marvel of modern planning, also represents a significant