In the rapidly evolving landscape of aerospace manufacturing, the demand for innovative solutions to create complex, lightweight components has never been more pressing, especially for parts like rocket nozzles and turbomachinery that require precision and durability. A groundbreaking development in additive manufacturing has emerged from a team of six Bachelor’s students at ETH Zurich, who have designed a novel rotating laser powder bed fusion (L-PBF) machine specifically tailored for cylindrical aerospace parts. This advancement, developed under the Swiss Academic Space Initiative (ARIS), promises to address longstanding challenges in producing intricate geometries with efficiency and quality. By reimagining the traditional L-PBF process, this technology introduces a fresh approach to fabricating critical components, potentially transforming how the aerospace industry tackles production constraints. The significance of this innovation lies not only in its technical prowess but also in its targeted application, setting a new benchmark for specialized manufacturing solutions.

Breaking New Ground in Additive Manufacturing

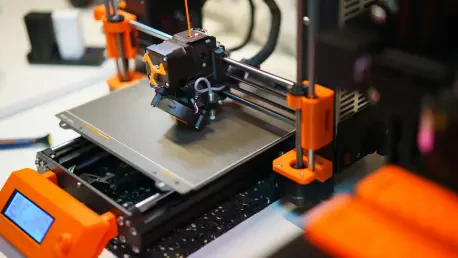

The core of this pioneering technology is a rotating platform that distinguishes it from conventional L-PBF systems, which typically rely on a rectilinear setup. Unlike traditional machines that pause for powder recoating after each layer is melted, this design enables continuous operation by synchronizing the laser scanning with the platform’s rotation. Such a mechanism proves especially advantageous for crafting axisymmetric components with large diameters and thin walls—features often found in aerospace applications like bi-liquid-fueled rocket nozzles. Moreover, the system optimizes inert gas flow, a critical factor in maintaining product quality during the printing process. This innovation reduces interruptions, streamlines production, and enhances the structural integrity of the final parts, marking a significant leap forward in the field of metal 3D printing. The focus on cylindrical geometries reflects a deliberate effort to address specific industry needs, highlighting the potential for customized manufacturing tools to solve niche problems.

Beyond the rotating mechanism, this machine introduces efficiencies through multi-material processing capabilities and reduced powder consumption. By integrating a system that supports varied material builds, it opens up possibilities for creating complex, hybrid components that meet diverse performance requirements in aerospace environments. The reduction in powder usage not only lowers costs but also minimizes waste, aligning with sustainability goals increasingly prioritized in industrial sectors. Additionally, the students tackled significant engineering challenges, such as aligning the scanning laser with a rotating gas inlet and powder supply. Custom solutions, including a rotatable gas connection and an automatic powder refill system, were developed to ensure seamless operation. These advancements underscore the ingenuity behind the project and demonstrate how targeted innovations can yield substantial improvements in manufacturing precision and resource efficiency, paving the way for broader adoption in specialized applications.

Overcoming Challenges and Scaling Potential

While the rotating L-PBF machine showcases remarkable potential, it is not without limitations that must be addressed for widespread industrial use. Currently, the technology is constrained by a maximum build volume, with component diameters limited to 20 centimeters, which restricts its application to smaller parts. Scaling up the process to accommodate larger dimensions and faster production speeds remains a key focus for the team. Efforts are underway to refine the system’s capacity, ensuring it can meet the demands of larger aerospace components without compromising quality or efficiency. Furthermore, synchronizing the intricate components of the machine posed significant hurdles during development, requiring custom engineering solutions that tested the team’s technical expertise. These challenges highlight the complexity of pioneering such a specialized tool, yet they also underscore the determination to push boundaries in additive manufacturing for high-stakes industries.

Looking ahead, the path to commercialization hinges on collaboration with industry partners who can provide the resources and expertise needed to elevate this technology. ETH Zurich has already filed a patent for the rotary multi-material L-PBF system, signaling confidence in its future applicability beyond academic research. The team’s ongoing work, as detailed in a publication in CIRP Annals, reflects a broader trend toward tailored additive manufacturing solutions that prioritize complex geometries, lightweighting, and conformal cooling—key priorities in aerospace design. Partnerships with industry leaders could accelerate advancements in build size and production speed, potentially transforming how critical components are fabricated. The emphasis on niche applications like rocket nozzles illustrates a strategic approach to innovation, balancing current constraints with ambitious goals for scalability and impact in a sector that thrives on cutting-edge technology.

Reflecting on a Milestone in Aerospace Innovation

Looking back, the development of this rotating L-PBF machine by ETH Zurich students marked a pivotal moment in the journey of additive manufacturing, particularly for the aerospace sector. The ingenuity behind a system that enabled continuous operation, supported multi-material builds, and improved gas flow for superior quality set a new standard for addressing geometric challenges in cylindrical part production. Despite early limitations in build volume, the determination to overcome technical obstacles through custom engineering solutions spoke volumes about the potential for academic research to drive industrial progress. As efforts to scale the technology gained momentum, the groundwork laid by this project inspired a renewed focus on specialized tools tailored to niche needs. Future steps involved forging strategic alliances with industry stakeholders to refine and expand the system’s capabilities, ensuring that the legacy of this innovation continued to shape manufacturing practices with precision and efficiency for years to come.