In the ever-evolving landscape of industrial automation, the unveiling of AI-driven cobots represents a groundbreaking shift. As the manufacturing world grapples with labor shortages, this strategic move introduces a solution poised to transform efficiency standards. At the forefront of this change is Schneider Electric’s integration of an AI Copilot within its EcoStruxure Automation Expert Platform, offering unprecedented opportunities for operational excellence.

Contextualizing the Technological Surge

Understanding the primary influences in industrial automation reveals the significance of these innovative strides. Over recent years, there has been an accelerated shift from traditional automation tools to comprehensive AI and cloud-based solutions, driven by a growing need for optimized productivity and operational efficiency. These advances establish why integrating AI into automation platforms isn’t simply a trend but a vital adaptation to meet the mounting demands of modern industries.

Emerging Prospects and Strategic Developments

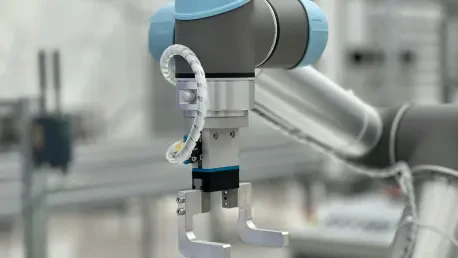

The central innovation from Schneider Electric involves the automation of routine tasks, empowering engineers to engage in complex problem-solving. This implementation, enhanced by Microsoft’s Azure AI Foundry, offers the cloud infrastructure essential for these advancements. The manufacturing sector’s labor deficits underline AI’s potential to bridge these gaps, enhancing effectiveness while inevitably navigating transitional challenges as legacy systems merge with innovative technologies.

Furthermore, the AI Copilot’s ability to expand and maintain production without workforce expansion is pivotal. By streamlining error-checking and code generation processes, it accelerates enhancements in production systems. As manufacturing moves toward software-defined paradigms, it also faces increased scrutiny over security and data management. Proper strategies, like regular workforce training and robust cybersecurity measures, become crucial.

Analyzing Regional Dynamics and Compliance Challenges

AI adoption varies considerably across regions, largely influenced by regulatory frameworks and market maturity levels. In places with stringent data governance, Schneider Electric’s AI initiatives must align with compliance standards while maximizing efficiency. The evolution of regulatory strategies will shape AI’s role in industry transformation, particularly amidst concerns such as employment displacement, which remains a central misconception.

Future Outlook and Transformative Implications

Manufacturing stands at the cusp of significant evolution, influenced by transformative trends such as the Internet of Things (IoT) and edge computing, which promise tighter synergy between AI systems and real-time operations. Schneider Electric, through its present initiatives, exemplifies early steps in intelligent manufacturing progress. In anticipating future regulatory developments, potential market shifts and evolving competitive landscapes remain key considerations.

Actionable Insights for Harnessing AI in Manufacturing

To maximize the substantial benefits of Schneider Electric’s AI Copilot, a proactive approach is essential. Investing in skill development ensures workers are adept at leveraging AI technologies. Comprehensive data management integrations further enhance operational effectiveness. By applying these strategies, businesses can achieve significant output increases without proportionally higher labor costs, supporting their market competitiveness.

In reflection, Schneider Electric’s strategic introduction of an AI Copilot signified a pivotal moment in industrial automation. As the manufacturing sector addressed challenges related to labor dynamics, the importance of integrating AI solutions to boost productivity and bridge workforce gaps became increasingly evident. Through Schneider Electric’s vision, the industrial domain continued its trajectory toward a digital and intelligent future, fortifying its future leadership position.